- Page 1 and 2:

u,. : - •

- Page 3:

% mm,

- Page 8 and 9:

\I>K BULLETIN 3 WATT m ^r+\ MINE *

- Page 10 and 11:

22 THE COAL TRADE BULLETIN. passing

- Page 12 and 13:

24 THE COAL TRADE BULLETIN. (c) Emp

- Page 14 and 15:

26 THE COAL TRADE BULLETIN. that ma

- Page 16 and 17:

28 THE COAL TRADE BULLETIN. while m

- Page 18 and 19:

30 THE COAL TRADE BULLETIN. oil-soa

- Page 20 and 21:

32 THE COAL TRADE BULLETIN. times g

- Page 22 and 23:

34 THE COAL TRADE BULLETIN. the cor

- Page 24 and 25:

36 THE COAL TRADE BULLETIN. can be

- Page 26 and 27:

38 THE COAL TRADE BULLETIN. Six hun

- Page 28 and 29:

40 THE COAL TRADE BULLETIN. "TOM" L

- Page 30 and 31:

42 THE C( )AL TRADE BULLETIN. PRODU

- Page 32 and 33:

44 THE COAL TRADE BULLETIN. little

- Page 34 and 35:

46 THE COAL TRADE BULLETIN. TELEPHO

- Page 36 and 37:

48 THE COAL TRADE BULLETIN. OPENING

- Page 38 and 39:

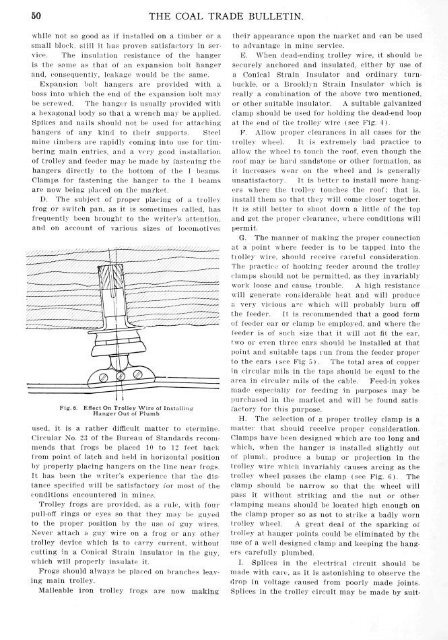

50 THE COAL TRADE BULLETIN. system

- Page 40 and 41:

52 THE COAL TRADE BULLETIN. ( as be

- Page 42 and 43:

54 THE COAL TRADE BULLETIN. TOWARDS

- Page 44 and 45:

56 THE COAL TRADE BULLETIN. COKE MA

- Page 46 and 47:

58 THE COAL TRADE BULLETIN. Timber

- Page 48 and 49:

20 THE COAL TRADE BULLETIN. quarter

- Page 50 and 51:

22 THE COAL TRADE BULLETIN. between

- Page 52 and 53:

24 THE COAL TRADE BULLETIN. KENTUCK

- Page 54 and 55:

26 THE COAL TRADE BULLETIN. PERTINE

- Page 56 and 57:

28 THE COAL TRADE BULLETIN. all acc

- Page 58 and 59:

30 THE COAL TRADE BULLETIN. matter

- Page 60 and 61:

32 operation. They shall not move t

- Page 62 and 63:

34 THE COAL TRADE BULLETIN. of said

- Page 64 and 65:

36 THE COAL TRADE BULLETIN. can be

- Page 66 and 67:

38 THE COAL TRADE BULLETIN. he of t

- Page 68 and 69:

40 THE COAL TRADE BULLETIN. JEFFREY

- Page 70 and 71:

42 THE COAL TRADE BULLETIN. THE SAM

- Page 72 and 73:

44 THE COAL TRADE BULLETIN. it is p

- Page 74 and 75:

46 THE COAL TRADE BULLETIN. THE EXP

- Page 76 and 77:

48 THE COAL TRADE BULLETIN. ally sl

- Page 78 and 79:

50 THE COAL TRADE BULLETIN. of boil

- Page 80 and 81:

Y2 THE COAL TRADE BULLETIN. THE TES

- Page 82 and 83:

54 THE COAL TRADE BULLETIN. of shov

- Page 84 and 85:

56 BESSEMER AND BASIC PIG IRON PROD

- Page 86 and 87:

58 THE COAL TRADE BULLETIN. Timber

- Page 88 and 89:

22 THE COAL TRADE BULLETIN. ket dar

- Page 90 and 91:

24 THE COAL TRADE BULLETIN. of the

- Page 92 and 93:

26 THE COAL TRADE BULLETIN. ogy and

- Page 94 and 95:

28 THE COAL TRADE BULLETIN. was, th

- Page 96 and 97:

3D THE COAL TRADE BULLETIN. pared p

- Page 98 and 99:

32 THE COAL TRADE BULLETIN. takes t

- Page 100 and 101:

34 THE COAL TRADE BULLETIN. • ) I

- Page 102 and 103:

36 THE COAL TRADE BULLETIN. COKE PR

- Page 104 and 105:

38 THE COAL TRADE BULLETIN. bottom

- Page 106 and 107:

40 THE COAL TRADE BULLETIN. Univers

- Page 108 and 109:

42 THE COAL TRADE BULLETIN. COKE PR

- Page 110 and 111:

41 THE COAL TRADE BULLETIN. day fil

- Page 112 and 113:

46 THE COAL TRADE BULLETIN. be able

- Page 114 and 115:

48 THE COAL TRADE BULLETIN. TEXT OF

- Page 116 and 117:

60 THE COAL TRADE BULLETIN. and the

- Page 118 and 119:

52 THE COAL TRADE BULLETIN. and in

- Page 120 and 121:

64 THE COAL TRADE BULLETIN. cars; w

- Page 122 and 123:

66 THE COAL TRADE BULLETIN. METHODS

- Page 124 and 125:

58 THE COAL TRADE BULLETIN. JAMISON

- Page 126 and 127:

22 THE COAL TRADE BULLETIN. that al

- Page 128 and 129:

24 THE COAL TRADE BULLETIN. Pittsbu

- Page 130 and 131:

26 THE COAL TRADE BULLETIN. AUDITOR

- Page 132 and 133:

28 THE COAL TRADE BULLETIN. owners

- Page 134 and 135:

30 THE COAL TRADE BULLETIN. W. P. R

- Page 136 and 137:

32 THE COAL TRADE BULLETIN. HANDS W

- Page 138 and 139:

34 THE COAL TRADE BULLETIN. NATURE

- Page 140 and 141:

36 THE COAL TRADE BULLETIN. in the

- Page 142 and 143:

38 THE COAL TRADE BULLETIN. hence t

- Page 144 and 145:

40 THE COAL TRADE BULLETIN. KENTUCK

- Page 146 and 147:

42 THE COAL TRADE BULLETIN. added t

- Page 148 and 149:

44 THE COAL TRADE BULLETIN. J. Seiv

- Page 150 and 151:

46 THE COAL TRADE BULLETIN. Meridit

- Page 152 and 153:

48 THE COAL TRADE BULLETIN. cate of

- Page 154 and 155:

50 THE COAL TRADE BULLETIN. sistant

- Page 156 and 157:

52 THE COAL TRADE BULLETIN. Section

- Page 158 and 159:

54 THE COAL TRADE BULLETIN. tries,

- Page 160 and 161:

56 THE COAL TRADE BULLETIN. employe

- Page 162 and 163:

58 FIRST SHIPMENT OF COAL TO PARAGU

- Page 164 and 165:

60 THE COAL TRADE BULLETIN.

- Page 166 and 167:

22 THE COAL TRADE BULLETIN. the pro

- Page 168 and 169:

'24 THE COAL TRADE BULLETIN. ship s

- Page 170 and 171:

26 THE COAL TRADE BULLETIN. WESTMOR

- Page 172 and 173:

28 THE COAL TRADE BULLETIN. 771.3 m

- Page 174 and 175:

30 THE COAL TRADE BULLETIN. ance of

- Page 176 and 177:

32 THE COAL TRADE BULLETIN. WEST VI

- Page 178 and 179:

34 THE COAL TRADE BULLETIN. off and

- Page 180 and 181:

36 THE COAL TRADE BULLETIN. Supplem

- Page 182 and 183:

38 THE COAL TRADE BULLETIN. fl CONS

- Page 184 and 185:

40 THE COAL TRADE BULLETIN. IS THE

- Page 186 and 187:

42 JUNE LAKE LEVELS. THE COAL TRADE

- Page 188 and 189:

44 THE COAL TRADE BULLETIN. for ove

- Page 190 and 191:

46 THE COAL TRADE BULLETIN. Section

- Page 192 and 193:

48 THE COAL TRADE BULLETIN. Section

- Page 194 and 195:

50 THE COAL TRADE BULLETIN. points

- Page 196 and 197:

52 THE COAL TRADE BULLETIN. 32. If

- Page 198 and 199:

64 THE COAL TRADE BULLETIN. tion of

- Page 200 and 201:

56 THE COAL TRADE BULLETIN. Text of

- Page 202 and 203:

58 THE COAL TRADE BULLETIN. Telepho

- Page 204 and 205:

60 THE COAL TRADE BULLETIN. (6~ ^ G

- Page 206 and 207:

22 THE COAL TRADE BULLETIN. quence,

- Page 208 and 209:

24 THE COAL TRADE BULLETIN. MINERS'

- Page 210 and 211:

26 THE COAL TRADE BULLETIN. BIG ATT

- Page 212 and 213:

28 THE COAL TRADE BULLETIN. them, a

- Page 214 and 215:

30 THE COAL TRADE BULLETIN. coupler

- Page 216 and 217:

32 THE COAL TRADE BULLETIN. intelli

- Page 218 and 219:

34 THE COAL TRADE BULLETIN. man thi

- Page 220 and 221:

36 THE COAL TRADE BULLETIN. vide ev

- Page 222 and 223:

38 THE COAL TRADE BULLETIN. PROGRAM

- Page 224 and 225:

40 THE COAL TRADE BULLETIN. PROGRAM

- Page 226 and 227:

42 THE COAL TRADE BULLETIN. LAKE OR

- Page 228 and 229:

44 THE COAL TRADE BULLETIN. the rea

- Page 230 and 231:

46 THE COAL TRADE BULLETIN. vision,

- Page 232 and 233:

48 THE COAL TRADE BULLETIN. surface

- Page 234 and 235:

50 THE COAL TRADE BULLETIN. ARTICLE

- Page 236 and 237:

52 THE COAL TRADE BULLETIN. their r

- Page 238 and 239:

64 THE COAL TRADE BULLETIN. of malf

- Page 240 and 241:

56 THE COAL TRADE BULLETIN. OHIO TA

- Page 242 and 243:

58 RECENT COAL TRADE PATENTS. The f

- Page 244 and 245:

22 THE COAL TRADE BULLETIN. shows t

- Page 246 and 247:

24 THE COAL TRADE BULLETIN. ENORMOU

- Page 248 and 249:

26 THE COAL TRADE BULLETIN. LAKE CO

- Page 250 and 251:

28 THE COAL TRADE BULLETIN. In addi

- Page 252 and 253:

30 THE COAL TRADE BULLETIN. operato

- Page 254 and 255:

32 THE COAL TRADE BULLETIN. than at

- Page 256 and 257:

34 THE COAL TRADE BULLETIN. careful

- Page 258 and 259:

36 THE COAL TRADE BULLETIN. about,

- Page 260 and 261:

38 THE COAL TRADE BULLETIN. boiler

- Page 262 and 263:

40 THE COAL TRADE BULLETIN. IDLE CA

- Page 264 and 265:

42 THE COAL TRADE BULLETIN. annum o

- Page 266 and 267:

44 THE COAL TRADE BULLETIN. their h

- Page 268 and 269:

46 THE COAL TRADE BULLETIN. positiv

- Page 270 and 271:

48 THE COAL TRADE BULLETIN. meeting

- Page 272 and 273:

50 THE COAL TRADE BULLETIN. The min

- Page 274 and 275:

52 THE COAL TRADE BULLETIN. man or

- Page 276 and 277:

64 THE COAL TRADE BULLETIN. whether

- Page 278 and 279:

66 THE COAL TRADE BULLETIN. RECENT

- Page 280 and 281:

58 THE COAL TRADE BULLETIN. THE J.

- Page 282 and 283:

22 THE COAL TRADE BULLETIN. their w

- Page 284 and 285:

24 THE COAL TRADE BULLETIN. DAVIS C

- Page 286 and 287:

26 THE COAL TRADE BULLETIN. enabled

- Page 288 and 289:

28 THE COAL TRADE BULLETIN. Public

- Page 290 and 291:

30 THE COAL TRADE BULLETIN. several

- Page 292 and 293:

32 THE COAL TRADE BULLETIN. pose in

- Page 294 and 295:

34 THE COAL TRADE BULLETIN. by such

- Page 296 and 297:

36 THE COAL TRADE BULLETIN. Inspect

- Page 298 and 299:

38 THE COAL TRADE BULLETIN. Adam Yo

- Page 300 and 301:

40 THE COAL TRADE BULLETIN. COAL PR

- Page 302 and 303:

42 THE COAL TRADE BULLETIN. composi

- Page 304 and 305:

44 THE COAL TRADE BULLETIN. mitted

- Page 306 and 307:

46 THE COAL TRADE BULLETIN. coal us

- Page 308 and 309:

48 THE COAL TRADE BULLETIN. was not

- Page 310 and 311:

50 THE COAL TRADE BULLETIN. The Cas

- Page 312 and 313:

52 THE COAL TRADE BULLETIN. these a

- Page 314 and 315:

64 THE COAL TRADE BULLETIN. Immedia

- Page 316 and 317:

56 THE COAL TRADE BULLETIN. COAL PR

- Page 318 and 319:

58 THE COAL TRADE BULLETIN. THE J.

- Page 320 and 321:

60 Production of The Finer Metals F

- Page 322 and 323:

22 THE COAL TRADE BULLETIN. is pick

- Page 324 and 325:

24 THE COAL TRADE BULLETIN. but tho

- Page 326 and 327:

26 THE COAL TRADE BULLETIN. 209.66S

- Page 328 and 329:

28 THE COAL TRADE BULLETIN. with th

- Page 330 and 331:

30 THE COAL TRADE BULLETIN. tive. H

- Page 332 and 333:

32 THE COAL TRADE BULLETIN. be prov

- Page 334 and 335:

34 THE COAL TRADE BULLETIN. Mr. H.

- Page 336 and 337:

36 THE COAL TRADE BULLETIN. as the

- Page 338 and 339:

38 THE COAL TRADE BULLETIN. run and

- Page 340 and 341:

40 THE COAL TRADE BULLETIN. Third.

- Page 342 and 343:

42 THE COAL TRADE BULLETIN. 6. As s

- Page 344 and 345:

44 THE COAL TRADE BULLETIN. LEHIGH

- Page 346 and 347:

46 THE COAL TRADE BULLETIN. by each

- Page 348 and 349:

48 THE COAL TRADE BULLETIN. inspect

- Page 350 and 351:

50 THE COAL TRADE BULLETIN. opening

- Page 352 and 353:

52 THE COAL TRADE BULLETIN. 6. When

- Page 354 and 355:

64 THE COAL TRADE BULLETIN. before

- Page 356 and 357:

56 PITTSBURGH DISTRICT CONSUMED THE

- Page 358 and 359:

58 THE J. B. SANBORN CO. Special Me

- Page 360 and 361:

60 THE COAL TRADE BULLETIN. J. H. S

- Page 362 and 363:

22 THE COAL TRADE BULLETIN. noticea

- Page 364 and 365:

24 THE COAL TRADE BULLETIN. T. L. L

- Page 366 and 367:

26 THE COAL TRADE BULLETIN. Pittsbu

- Page 368 and 369:

28 THE COAL TRADE BULLETIN. develop

- Page 370 and 371:

30 THE COAL TRADE BULLETIN. may be

- Page 372 and 373:

32 THE COAL TRADE BULLETIN. j MININ

- Page 374 and 375:

34 THE COAL TRADE BULLETIN. depende

- Page 376 and 377:

36 THE COAL TRADE BULLETIN. be used

- Page 378 and 379:

38 THE COAL TRADE BULLETIN. duction

- Page 380 and 381:

40 THE COAL TRADE BULLETIN. DISTRIC

- Page 382 and 383:

42 THE COAL TRADE BULLETIN. not by

- Page 384 and 385:

44 THE COAL TRADE BULLETIN. same ac

- Page 386 and 387:

46 THE COAL TRADE BULLETIN. MINE IN

- Page 388 and 389:

48 THE COAL TRADE BULLETIN. water g

- Page 390 and 391:

50 THE COAL TRADE BULLETIN. placed

- Page 392 and 393:

52 THE COAL TRADE BULLETIN. trie la

- Page 394 and 395:

64 THE COAL TRADE BULLETIN. THE UND

- Page 396 and 397:

56 THE COAL TRADE BULLETIN. NEW BRU

- Page 398 and 399:

58 THE COAL TRADE BULLETIN. THE J.

- Page 400 and 401:

60 THE COAL TRADE BULLETIN. Here is

- Page 402 and 403:

24 THE COAL TRADE BULLETIN. are $1.

- Page 404 and 405:

26 THE COAL TRADE BULLETIN panies,

- Page 406 and 407:

28 IHE COAL TRADE BULLETIN. "comedy

- Page 408 and 409:

30 THE COAL TRADE BULLETIN. PITTSBU

- Page 410 and 411:

32 THE COAL TRADE BULLETIN. as this

- Page 412 and 413:

34 THE COAL TRADE BULLETIN. interfe

- Page 414 and 415:

3fi THE COAL TRADE BULLETIN. divert

- Page 416 and 417: 38 THE COAL TRADE BULLETIN. chises

- Page 418 and 419: 40 THE COAL TRADE BULLETIN. 000 wor

- Page 420 and 421: 42 THE COAL TRADE BULLETIN. RESULTS

- Page 422 and 423: 44 THE COAL TRADE BULLETIN. der the

- Page 424 and 425: 46 THE COAL TRADE BULLETIN. Nationa

- Page 426 and 427: 48 THE COAL TRADE BULLETIN. Iron Ci

- Page 428 and 429: 50 THE COAL TRADE BULLETIN. Colorad

- Page 430 and 431: 52 Alaskan Problems. (Continued fro

- Page 432 and 433: 54 THE COAL TRADE BULLETIN. develop

- Page 434 and 435: 66 THE COAL TRADE BULLETIN. GOVERNM

- Page 436 and 437: 58 THE COAL TRADE BULLETIN. THE J.

- Page 438 and 439: 60 THE COAL TRADE BULLETIN. LARGEST

- Page 440 and 441: 24 THE COAL TRADE BULLETIN. paring

- Page 442 and 443: 26 THE COAL TRADE BULLETIN. OKLAHOM

- Page 444 and 445: 28 THE COAL TRADE BULLETIN. Mountai

- Page 446 and 447: .'50 THE COAL TRADE BULLETIN. throu

- Page 448 and 449: 32 THE COAL TRADE BULLETIN. IRON OR

- Page 450 and 451: 34 THE COAL TRADE BULLETIN. from 11

- Page 452 and 453: 36 THE COAL TRADE BULLETIN. WILL MA

- Page 454 and 455: 38 THE COAL TRADE BULLETIN. install

- Page 456 and 457: 40 THE COAL TRADE BULLETIN. Slate c

- Page 458 and 459: 42 THE COAL TRADE BULLETIN. Great s

- Page 460 and 461: 44 THE COAL TRADE BULLETIN. ENFORCI

- Page 462 and 463: 46 THE COAL TRADE BULLETIN. FAST WO

- Page 464 and 465: 46 THE COAL TRADE BULLETIN. factory

- Page 468 and 469: 52 THE COAL TRADE BULLETIN. STEEL M

- Page 470 and 471: 54 THE COAL TRADE BULLETIN. will be

- Page 472 and 473: 56 THE COAL TRADE BULLETIN. The bod

- Page 474 and 475: 58 THE COAL TRADE BULLETIN. The sal

- Page 476 and 477: 60 THE COAL TRADE BULLETIN. PHILIPP

- Page 478: 62 THE COAL TRADE BULLETIN. Atlanti

- Page 483 and 484: ,,.. ft* f&V2£P»i3sorR«d