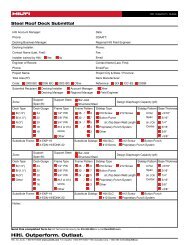

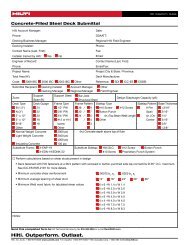

Steel Protection Submittal - Hilti Egypt

Steel Protection Submittal - Hilti Egypt

Steel Protection Submittal - Hilti Egypt

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Fire <strong>Protection</strong> <strong>Steel</strong> Spray CFP-S WB<br />

Fire <strong>Protection</strong> <strong>Steel</strong> Spray<br />

CFP-S WB<br />

Product description<br />

■■ Fire protection dispersion to help protect load bearing steel structures<br />

in interior environments against the effects of fire<br />

Product features<br />

■■ Tested to ASTM E119 for up to 4h fire rating<br />

■■ Water Based, low VOC — allows for fast, easy and safe clean up<br />

■■ Reduced dry time permits additional coats to be applied faster<br />

■■ Infinite color options possible with approved topcoats<br />

Areas of application<br />

■■ Wide flange steel columns<br />

■■ Hollow steel sections<br />

■■ Restrained and unrestrained beams<br />

■■ Restrained and unrestrained concrete and steel floor units<br />

Primer<br />

■■ The primer used should be of the phenolic resin modified alkyd type. A<br />

corresponding listing of tested and approved primers can be found at<br />

the <strong>Hilti</strong> Technical Services Department.<br />

Top coats<br />

If desired or required the following tested and approved top coats may be<br />

applied for decorative purposes.<br />

■■ Glidden Premium Exterior Latex Semi-Gloss GL68XX<br />

®<br />

■ ■ Benjamin Moore Moorglo Soft Gloss Fortified Acrylic House Paint<br />

■■ Sherwin Williams <strong>Steel</strong> Master 9500 30% Silicone Alkyd<br />

UL-Listing<br />

■■ BXUV.Y611 — for wide flange steel columns<br />

■■ BXUV.Y612 — for hollow sections columns<br />

■■ BXUV.N631 — for beams<br />

■■ BXUV.D975 — for concrete and steel floor units<br />

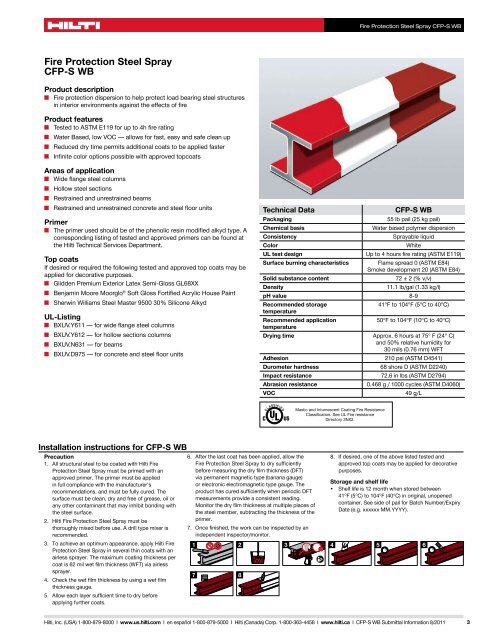

Technical Data<br />

Packaging<br />

Chemical basis<br />

Consistency<br />

Color<br />

CFP-S WB<br />

55 lb pail (25 kg pail)<br />

Water based polymer dispersion<br />

Sprayable liquid<br />

White<br />

UL test design Up to 4 hours fire rating (ASTM E119)<br />

Surface burning characteristics Flame spread 0 (ASTM E84)<br />

Smoke development 20 (ASTM E84)<br />

Solid substance content<br />

Density<br />

72 ± 2 (% v/v)<br />

11.1 lb/gal (1.33 kg/l)<br />

pH value 8-9<br />

Recommended storage<br />

41°F to 104°F (5°C to 40°C)<br />

temperature<br />

Recommended application<br />

50°F to 104°F (10°C to 40°C)<br />

temperature<br />

Drying time Approx. 6 hours at 75° F (24° C)<br />

and 50% relative humidity for<br />

30 mils (0.76 mm) WFT<br />

Adhesion 210 psi (ASTM D4541)<br />

Durometer hardness 68 shore D (ASTM D2240)<br />

Impact resistance 72.6 in lbs (ASTM D2794)<br />

Abrasion resistance 0.468 g / 1000 cycles (ASTM D4060)<br />

VOC<br />

49 g/L<br />

Mastic and Intumescent Coating Fire Resistance<br />

Classification. See UL Fire resistance<br />

Directory 3NX2.<br />

Installation instructions for CFP-S WB<br />

Precaution<br />

1. All structural steel to be coated with <strong>Hilti</strong> Fire<br />

<strong>Protection</strong> <strong>Steel</strong> Spray must be primed with an<br />

approved primer. The primer must be applied<br />

in full compliance with the manufacturer’s<br />

recommendations, and must be fully cured. The<br />

surface must be clean, dry and free of grease, oil or<br />

any other contaminant that may inhibit bonding with<br />

the steel surface.<br />

2. <strong>Hilti</strong> Fire <strong>Protection</strong> <strong>Steel</strong> Spray must be<br />

thoroughly mixed before use. A drill type mixer is<br />

recommended.<br />

3. To achieve an optimum appearance, apply <strong>Hilti</strong> Fire<br />

<strong>Protection</strong> <strong>Steel</strong> Spray in several thin coats with an<br />

airless sprayer. The maximum coating thickness per<br />

coat is 62 mil wet film thickness (WFT) via airless<br />

sprayer.<br />

4. Check the wet film thickness by using a wet film<br />

thickness gauge.<br />

5. Allow each layer sufficient time to dry before<br />

applying further coats.<br />

6. After the last coat has been applied, allow the<br />

Fire <strong>Protection</strong> <strong>Steel</strong> Spray to dry sufficiently<br />

before measuring the dry film thickness (DFT)<br />

via permanent magnetic type (banana gauge)<br />

or electronic electromagnetic type gauge. The<br />

product has cured sufficiently when periodic DFT<br />

measurements provide a consistent reading.<br />

Monitor the dry film thickness at multiple places of<br />

the steel member, subtracting the thickness of the<br />

primer.<br />

7. Once finished, the work can be inspected by an<br />

independent inspector/monitor.<br />

8. If desired, one of the above listed tested and<br />

approved top coats may be applied for decorative<br />

purposes.<br />

Storage and shelf life<br />

• Shelf life is 12 month when stored between<br />

41°F (5°C) to 104°F (40°C) in original, unopened<br />

container. See side of pail for Batch Number/Expiry<br />

Date (e.g. xxxxxx MM.YYYY).<br />

1 2 3 4 5 6<br />

7 8<br />

<strong>Hilti</strong>, Inc. (USA) 1-800-879-8000 I www.us.hilti.com I en español 1-800-879-5000 I <strong>Hilti</strong> (Canada) Corp. 1-800-363-4458 I www.hilti.ca I CFP-S WB <strong>Submittal</strong> Information 8/2011<br />

3