Steel Protection Submittal - Hilti Egypt

Steel Protection Submittal - Hilti Egypt

Steel Protection Submittal - Hilti Egypt

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

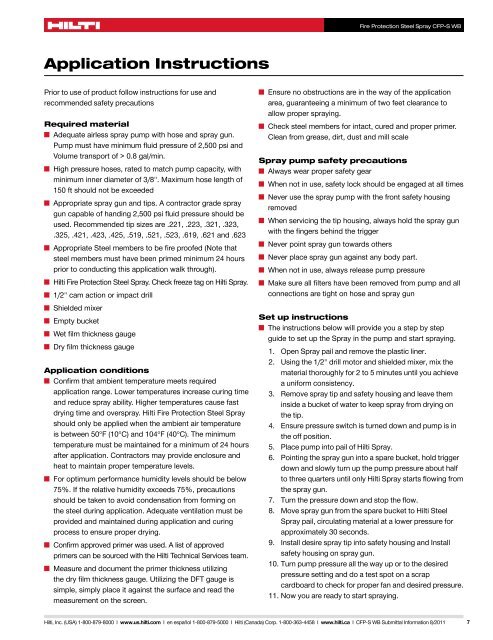

Fire <strong>Protection</strong> <strong>Steel</strong> Spray CFP-S WB<br />

Application Instructions<br />

Prior to use of product follow instructions for use and<br />

recommended safety precautions<br />

Required material<br />

■■ Adequate airless spray pump with hose and spray gun.<br />

Pump must have minimum fluid pressure of 2,500 psi and<br />

Volume transport of > 0.8 gal/min.<br />

■■ High pressure hoses, rated to match pump capacity, with<br />

minimum inner diameter of 3/8". Maximum hose length of<br />

150 ft should not be exceeded<br />

■■ Appropriate spray gun and tips. A contractor grade spray<br />

gun capable of handing 2,500 psi fluid pressure should be<br />

used. Recommended tip sizes are .221, .223, .321, .323,<br />

.325, .421, .423, .425, .519, .521, .523, .619, .621 and .623<br />

■■ Appropriate <strong>Steel</strong> members to be fire proofed (Note that<br />

steel members must have been primed minimum 24 hours<br />

prior to conducting this application walk through).<br />

■■ <strong>Hilti</strong> Fire <strong>Protection</strong> <strong>Steel</strong> Spray. Check freeze tag on <strong>Hilti</strong> Spray.<br />

■■ 1/2" cam action or impact drill<br />

■■ Shielded mixer<br />

■■ Empty bucket<br />

■■ Wet film thickness gauge<br />

■■ Dry film thickness gauge<br />

Application conditions<br />

■■ Confirm that ambient temperature meets required<br />

application range. Lower temperatures increase curing time<br />

and reduce spray ability. Higher temperatures cause fast<br />

drying time and overspray. <strong>Hilti</strong> Fire <strong>Protection</strong> <strong>Steel</strong> Spray<br />

should only be applied when the ambient air temperature<br />

is between 50°F (10°C) and 104°F (40°C). The minimum<br />

temperature must be maintained for a minimum of 24 hours<br />

after application. Contractors may provide enclosure and<br />

heat to maintain proper temperature levels.<br />

■■ For optimum performance humidity levels should be below<br />

75%. If the relative humidity exceeds 75%, precautions<br />

should be taken to avoid condensation from forming on<br />

the steel during application. Adequate ventilation must be<br />

provided and maintained during application and curing<br />

process to ensure proper drying.<br />

■■ Confirm approved primer was used. A list of approved<br />

primers can be sourced with the <strong>Hilti</strong> Technical Services team.<br />

■■ Measure and document the primer thickness utilizing<br />

the dry film thickness gauge. Utilizing the DFT gauge is<br />

simple, simply place it against the surface and read the<br />

measurement on the screen.<br />

■■ Ensure no obstructions are in the way of the application<br />

area, guaranteeing a minimum of two feet clearance to<br />

allow proper spraying.<br />

■■ Check steel members for intact, cured and proper primer.<br />

Clean from grease, dirt, dust and mill scale<br />

Spray pump safety precautions<br />

■■ Always wear proper safety gear<br />

■■ When not in use, safety lock should be engaged at all times<br />

■■ Never use the spray pump with the front safety housing<br />

removed<br />

■■ When servicing the tip housing, always hold the spray gun<br />

with the fingers behind the trigger<br />

■■ Never point spray gun towards others<br />

■■ Never place spray gun against any body part.<br />

■■ When not in use, always release pump pressure<br />

■■ Make sure all filters have been removed from pump and all<br />

connections are tight on hose and spray gun<br />

Set up instructions<br />

■■ The instructions below will provide you a step by step<br />

guide to set up the Spray in the pump and start spraying.<br />

1. Open Spray pail and remove the plastic liner.<br />

2. Using the 1/2" drill motor and shielded mixer, mix the<br />

material thoroughly for 2 to 5 minutes until you achieve<br />

a uniform consistency.<br />

3. Remove spray tip and safety housing and leave them<br />

inside a bucket of water to keep spray from drying on<br />

the tip.<br />

4. Ensure pressure switch is turned down and pump is in<br />

the off position.<br />

5. Place pump into pail of <strong>Hilti</strong> Spray.<br />

6. Pointing the spray gun into a spare bucket, hold trigger<br />

down and slowly turn up the pump pressure about half<br />

to three quarters until only <strong>Hilti</strong> Spray starts flowing from<br />

the spray gun.<br />

7. Turn the pressure down and stop the flow.<br />

8. Move spray gun from the spare bucket to <strong>Hilti</strong> <strong>Steel</strong><br />

Spray pail, circulating material at a lower pressure for<br />

approximately 30 seconds.<br />

9. Install desire spray tip into safety housing and Install<br />

safety housing on spray gun.<br />

10. Turn pump pressure all the way up or to the desired<br />

pressure setting and do a test spot on a scrap<br />

cardboard to check for proper fan and desired pressure.<br />

11. Now you are ready to start spraying.<br />

<strong>Hilti</strong>, Inc. (USA) 1-800-879-8000 I www.us.hilti.com I en español 1-800-879-5000 I <strong>Hilti</strong> (Canada) Corp. 1-800-363-4458 I www.hilti.ca I CFP-S WB <strong>Submittal</strong> Information 8/2011<br />

7