Untitled - UNU-IAS - United Nations University

Untitled - UNU-IAS - United Nations University

Untitled - UNU-IAS - United Nations University

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

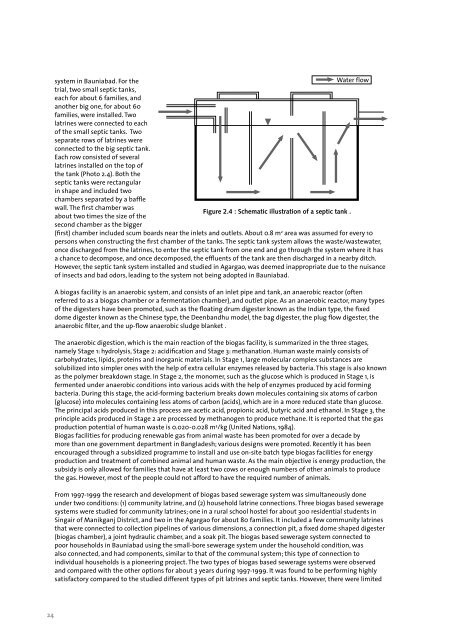

system in Bauniabad. For the<br />

<br />

trial, two small septic tanks,<br />

each for about 6 families, and<br />

another big one, for about 60<br />

families, were installed. Two<br />

latrines were connected to each<br />

of the small septic tanks. Two<br />

separate rows of latrines were<br />

connected to the big septic tank.<br />

Each row consisted of several<br />

latrines installed on the top of<br />

the tank (Photo 2.4). Both the<br />

septic tanks were rectangular<br />

in shape and included two<br />

chambers separated by a baffle<br />

wall. The first chamber was<br />

<br />

about two times the size of the<br />

second chamber as the bigger<br />

(first) chamber included scum boards near the inlets and outlets. About 0.8 m 2 area was assumed for every 10<br />

persons when constructing the first chamber of the tanks. The septic tank system allows the waste/wastewater,<br />

once discharged from the latrines, to enter the septic tank from one end and go through the system where it has<br />

a chance to decompose, and once decomposed, the effluents of the tank are then discharged in a nearby ditch.<br />

However, the septic tank system installed and studied in Agargao, was deemed inappropriate due to the nuisance<br />

of insects and bad odors, leading to the system not being adopted in Bauniabad.<br />

A biogas facility is an anaerobic system, and consists of an inlet pipe and tank, an anaerobic reactor (often<br />

referred to as a biogas chamber or a fermentation chamber), and outlet pipe. As an anaerobic reactor, many types<br />

of the digesters have been promoted, such as the floating drum digester known as the Indian type, the fixed<br />

dome digester known as the Chinese type, the Deenbandhu model, the bag digester, the plug flow digester, the<br />

anaerobic filter, and the up-flow anaerobic sludge blanket .<br />

The anaerobic digestion, which is the main reaction of the biogas facility, is summarized in the three stages,<br />

namely Stage 1: hydrolysis, Stage 2: acidification and Stage 3: methanation. Human waste mainly consists of<br />

carbohydrates, lipids, proteins and inorganic materials. In Stage 1, large molecular complex substances are<br />

solubilized into simpler ones with the help of extra cellular enzymes released by bacteria. This stage is also known<br />

as the polymer breakdown stage. In Stage 2, the monomer, such as the glucose which is produced in Stage 1, is<br />

fermented under anaerobic conditions into various acids with the help of enzymes produced by acid forming<br />

bacteria. During this stage, the acid-forming bacterium breaks down molecules containing six atoms of carbon<br />

(glucose) into molecules containing less atoms of carbon (acids), which are in a more reduced state than glucose.<br />

The principal acids produced in this process are acetic acid, propionic acid, butyric acid and ethanol. In Stage 3, the<br />

principle acids produced in Stage 2 are processed by methanogen to produce methane. It is reported that the gas<br />

production potential of human waste is 0.020-0.028 m 3 /kg (<strong>United</strong> <strong>Nations</strong>, 1984).<br />

Biogas facilities for producing renewable gas from animal waste has been promoted for over a decade by<br />

more than one government department in Bangladesh; various designs were promoted. Recently it has been<br />

encouraged through a subsidized programme to install and use on-site batch type biogas facilities for energy<br />

production and treatment of combined animal and human waste. As the main objective is energy production, the<br />

subsidy is only allowed for families that have at least two cows or enough numbers of other animals to produce<br />

the gas. However, most of the people could not afford to have the required number of animals.<br />

From 1997-1999 the research and development of biogas based sewerage system was simultaneously done<br />

under two conditions: (1) community latrine, and (2) household latrine connections. Three biogas based sewerage<br />

systems were studied for community latrines; one in a rural school hostel for about 300 residential students in<br />

Singair of Manikganj District, and two in the Agargao for about 80 families. It included a few community latrines<br />

that were connected to collection pipelines of various dimensions, a connection pit, a fixed dome shaped digester <br />

(biogas chamber), a joint hydraulic chamber, and a soak pit. The biogas based sewerage system connected to <br />

poor households in Bauniabad using the small-bore sewerage system under the household condition, was <br />

also connected, and had components, similar to that of the communal system; this type of connection to<br />

individual households is a pioneering project. The two types of biogas based sewerage systems were observed<br />

<br />

and compared with the other options for about 3 years during 1997-1999. It was found to be performing highly <br />

satisfactory compared to the studied different types of pit latrines and septic tanks. However, there were limited <br />

<br />

<br />

24