singapore engineer singapore engineer singapore engineer

singapore engineer singapore engineer singapore engineer

singapore engineer singapore engineer singapore engineer

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

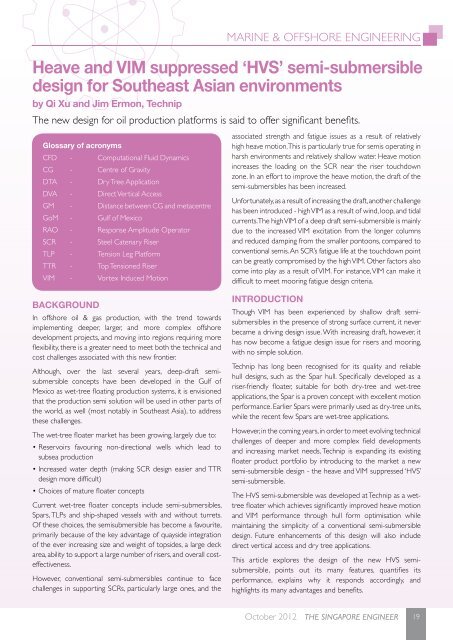

MARINE & OFFSHORE ENGINEERING<br />

Heave and VIM suppressed ‘HVS’ semi-submersible<br />

design for Southeast Asian environments<br />

by Qi Xu and Jim Ermon, Technip<br />

The new design for oil production platforms is said to offer significant benefits.<br />

Glossary of acronyms<br />

CFD - Computational Fluid Dynamics<br />

CG - Centre of Gravity<br />

DTA - Dry Tree Application<br />

DVA - Direct Vertical Access<br />

GM - Distance between CG and metacentre<br />

GoM - Gulf of Mexico<br />

RAO - Response Amplitude Operator<br />

SCR - Steel Catenary Riser<br />

TLP - Tension Leg Platform<br />

TTR - Top Tensioned Riser<br />

VIM - Vortex Induced Motion<br />

BACKGROUND<br />

In offshore oil & gas production, with the trend towards<br />

implementing deeper, larger, and more complex offshore<br />

development projects, and moving into regions requiring more<br />

flexibility, there is a greater need to meet both the technical and<br />

cost challenges associated with this new frontier.<br />

Although, over the last several years, deep-draft semisubmersible<br />

concepts have been developed in the Gulf of<br />

Mexico as wet-tree floating production systems, it is envisioned<br />

that the production semi solution will be used in other parts of<br />

the world, as well (most notably in Southeast Asia), to address<br />

these challenges.<br />

The wet-tree floater market has been growing, largely due to:<br />

• Reservoirs favouring non-directional wells which lead to<br />

subsea production<br />

• Increased water depth (making SCR design easier and TTR<br />

design more difficult)<br />

• Choices of mature floater concepts<br />

Current wet-tree floater concepts include semi-submersibles,<br />

Spars, TLPs and ship-shaped vessels with and without turrets.<br />

Of these choices, the semisubmersible has become a favourite,<br />

primarily because of the key advantage of quayside integration<br />

of the ever increasing size and weight of topsides, a large deck<br />

area, ability to support a large number of risers, and overall costeffectiveness.<br />

However, conventional semi-submersibles continue to face<br />

challenges in supporting SCRs, particularly large ones, and the<br />

associated strength and fatigue issues as a result of relatively<br />

high heave motion. This is particularly true for semis operating in<br />

harsh environments and relatively shallow water. Heave motion<br />

increases the loading on the SCR near the riser touchdown<br />

zone. In an effort to improve the heave motion, the draft of the<br />

semi-submersibles has been increased.<br />

Unfortunately, as a result of increasing the draft, another challenge<br />

has been introduced - high VIM as a result of wind, loop, and tidal<br />

currents. The high VIM of a deep draft semi-submersible is mainly<br />

due to the increased VIM excitation from the longer columns<br />

and reduced damping from the smaller pontoons, compared to<br />

conventional semis. An SCR’s fatigue life at the touchdown point<br />

can be greatly compromised by the high VIM. Other factors also<br />

come into play as a result of VIM. For instance, VIM can make it<br />

difficult to meet mooring fatigue design criteria.<br />

INTRODUCTION<br />

Though VIM has been experienced by shallow draft semisubmersibles<br />

in the presence of strong surface current, it never<br />

became a driving design issue. With increasing draft, however, it<br />

has now become a fatigue design issue for risers and mooring,<br />

with no simple solution.<br />

Technip has long been recognised for its quality and reliable<br />

hull designs, such as the Spar hull. Specifically developed as a<br />

riser-friendly floater, suitable for both dry-tree and wet-tree<br />

applications, the Spar is a proven concept with excellent motion<br />

performance. Earlier Spars were primarily used as dry-tree units,<br />

while the recent few Spars are wet-tree applications.<br />

However, in the coming years, in order to meet evolving technical<br />

challenges of deeper and more complex field developments<br />

and increasing market needs, Technip is expanding its existing<br />

floater product portfolio by introducing to the market a new<br />

semi-submersible design - the heave and VIM suppressed ‘HVS’<br />

semi-submersible.<br />

The HVS semi-submersible was developed at Technip as a wettree<br />

floater which achieves significantly improved heave motion<br />

and VIM performance through hull form optimisation while<br />

maintaining the simplicity of a conventional semi-submersible<br />

design. Future enhancements of this design will also include<br />

direct vertical access and dry tree applications.<br />

This article explores the design of the new HVS semisubmersible,<br />

points out its many features, quantifies its<br />

performance, explains why it responds accordingly, and<br />

highlights its many advantages and benefits.<br />

October 2012 THE SINGAPORE ENGINEER<br />

19