Explosion protection.pdf - Siemens

Explosion protection.pdf - Siemens

Explosion protection.pdf - Siemens

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

F1<br />

F2<br />

F3<br />

F4<br />

F5<br />

F6<br />

On<br />

Off<br />

Ent<br />

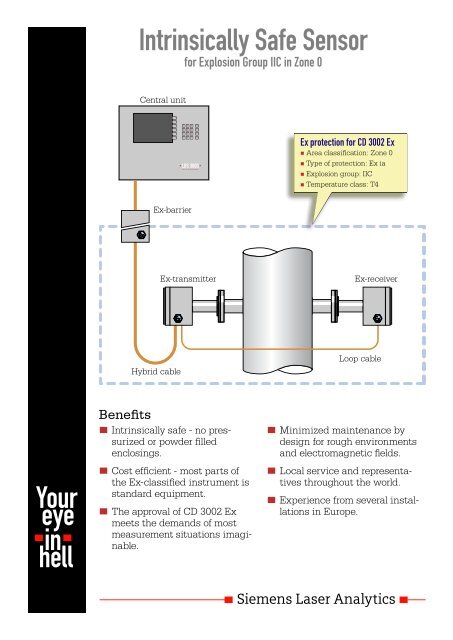

Intrinsically Safe Sensor<br />

for <strong>Explosion</strong> Group IIC in Zone 0<br />

Central unit<br />

7 8 9 Del<br />

4 5 6<br />

1 2 3<br />

• 0 —<br />

LDS 3000<br />

Laser Diode Spectrometer<br />

Ex <strong>protection</strong> for CD 3002 Ex<br />

• Area classification: Zone 0<br />

• Type of <strong>protection</strong>: Ex ia<br />

• <strong>Explosion</strong> group: IIC<br />

• Temperature class: T4<br />

Ex-barrier<br />

Ex-transmitter<br />

Ex-receiver<br />

Hybrid cable<br />

Loop cable<br />

Your<br />

eye<br />

in<br />

hell<br />

Benefits<br />

• Intrinsically safe - no pressurized<br />

or powder filled<br />

enclosings.<br />

• Cost efficient - most parts of<br />

the Ex-classified instrument is<br />

standard equipment.<br />

• The approval of CD 3002 Ex<br />

meets the demands of most<br />

measurement situations imaginable.<br />

• Minimized maintenance by<br />

design for rough environments<br />

and electromagnetic fields.<br />

• Local service and representatives<br />

throughout the world.<br />

• Experience from several installations<br />

in Europe.<br />

<strong>Siemens</strong> Laser Analytics

<strong>Explosion</strong> <strong>protection</strong> class for CD 3002 Ex<br />

Introduction<br />

One major advantage of the <strong>Siemens</strong> Laser Analytics concept<br />

with a central unit and sensors interconnected with<br />

optical fibres is the relative simplicity to achieve Ex-<strong>protection</strong>.<br />

Only a limited, low energy part of the electronics is<br />

located at the measurement site. The distance between the<br />

central unit and the sensors can be several hundred meters.<br />

The LDS 3000 system has an approval for use in a hazardous<br />

environment were explosive gases are in use.<br />

CD 3002 Ex combined with i.e. steam purging will provide<br />

a flexible, virtually maintenance free measurement situation<br />

in the most difficult and hazardous places.<br />

Approval<br />

The concept of the Ex approval is that the central unit<br />

is unchanged from a standard unit and that a special Ex<br />

sensor pair is used in the measurement zone. In addition<br />

to this an Ex barrier is added at the point of entry into<br />

the hazardous zone. An absolute condition for the approval<br />

is that the equipment is set up according to the <strong>Siemens</strong><br />

Laser Analytics drawing, ADM 3040 3050.<br />

The <strong>protection</strong> for CD 3002 Ex is as follows:<br />

• Area classification: Zone 0. Flammable material may be<br />

present continuously or for long periods.<br />

• Type of <strong>protection</strong>: Ex ia. The equipment present in the<br />

hazardous area is intrinsically safe.<br />

• <strong>Explosion</strong> group: IIC. This corresponds to a gas group<br />

containing Acetylene and Hydrogen.<br />

• Temperature class: T4. The maximum surface temperature<br />

on the equipment is 135°C and the ignition temperature<br />

of the gas or vapour is between 135°C and<br />

200°C.<br />

The Ingress <strong>protection</strong> is IP 65 and the ambient temperature<br />

must be between -30°C and +60°C.<br />

Labelling<br />

There are three different points that require Ex labels, the<br />

barrier, the transmitter and the receiver. These labels are<br />

similar and states <strong>protection</strong> class and installation requirements.<br />

The label below is for the receiver.<br />

<strong>Siemens</strong> Laser Analytics<br />

Östergårdsgatan 2-4, Box 5065, 402 22 Gbg, Sweden<br />

Gas Analyser model CD 3002 Ex<br />

Warning: For installation follow System drawing 3040-3050 1C<br />

Art. no. 3040-3052 1D Receiver Ex<br />

DEMKO<br />

SYST 00E. 127762<br />

EEx ia IIC T4<br />

IP 65<br />

-30 ˚C < Ta < +60 ˚C<br />

Ex Applications<br />

Gas analysis plays an important role in many applications.<br />

Many of these require explosion <strong>protection</strong> of the equipment<br />

exposed to the measuring area. The following are<br />

examples of such applications:<br />

• Petrochemical industry<br />

• Mining industry<br />

• Chemical industry<br />

Installation and Operation<br />

LDS 3000 with CD 3002 Ex is very easy to install and<br />

operate. The analyser is designed to handle the very rough<br />

industrial environment consisting of high temperature,<br />

electromagnetic fields, high dust loads, etc. The system is<br />

composed of four parts.<br />

• The central unit (standard)<br />

• Hybrid cable (standard)<br />

• The Ex-barrier<br />

• The Ex-sensor<br />

The transmitter and the receiver in the sensor are interconnected<br />

with a loop cable and the sensor is connected to<br />

the central unit with a hybrid cable containing fibre optics<br />

and, at the point of entry into the hazardous area, an Exbarrier<br />

for the electrical power. The length of this cable can<br />

exceed 1 km.<br />

Features<br />

The system has a lot of unique points which makes it very<br />

suitable for long term process operation in environments<br />

with Ex requirements.<br />

• Low maintenance<br />

• Intrinsically safe<br />

• No gas sampling - in-situ measurements<br />

• Three measuring points simultaneously. Not all has to<br />

be equipped with CD 3002 Ex - only the ones in the<br />

hazardous area.<br />

References (complete on the web)<br />

Shell Sweden 1998<br />

Refinery • Zone 2 • NH 3 0-25 ppm<br />

Ciba Italy 2000<br />

Chemical • Zone 0 • O 2 0-5%<br />

Contact<br />

<strong>Siemens</strong> Laser Analytics (headquarters)<br />

Marketing Director<br />

Jan Grimbrandt • jan.grimbrandt@siemens.com<br />

Marketing Assistant<br />

Michaela Hermansson • michaela.hermansson@siemens.com<br />

Phone: +46 (0)31 776 86 00<br />

<strong>Siemens</strong> Laser Analytics objective is not only to supply gas analysers measuring different gases in complicated<br />

and hostile environments – we also want to participate in managing difficult processes containing<br />

gas compounds by adding know-how, experience and professionallity in every aspect of the measurement.<br />

<strong>Siemens</strong> Laser Analytics<br />

<strong>Siemens</strong> Laser Analytics AB • Box 5065 • SE-402 22 Göteborg • Sweden • www.siemens.se/sla