Download complete journal in PDF form - Academy Publish

Download complete journal in PDF form - Academy Publish

Download complete journal in PDF form - Academy Publish

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PARAMETRIC STUDY OF SANDWICH PANEL BUCKLING IN COMPOSITE WIND TURBINE BLADES<br />

Shicong Miao, Steven Donaldson, and Elias Toubia<br />

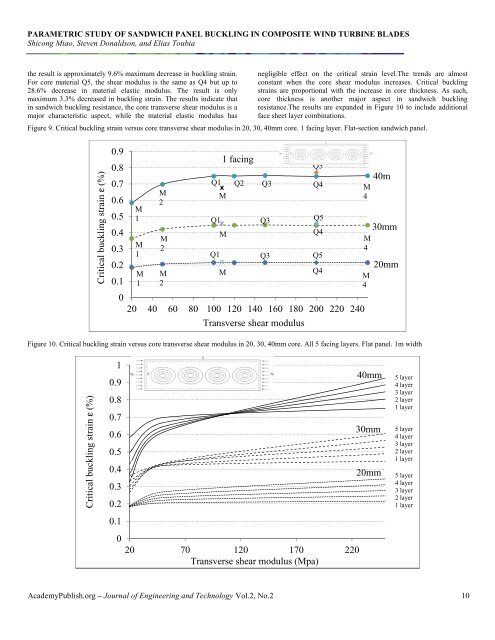

the result is approximately 9.6% maximum decrease <strong>in</strong> buckl<strong>in</strong>g stra<strong>in</strong>.<br />

For core material Q5, the shear modulus is the same as Q4 but up to<br />

28.6% decrease <strong>in</strong> material elastic modulus. The result is only<br />

maximum 3.3% decreased <strong>in</strong> buckl<strong>in</strong>g stra<strong>in</strong>. The results <strong>in</strong>dicate that<br />

<strong>in</strong> sandwich buckl<strong>in</strong>g resistance, the core transverse shear modulus is a<br />

major characteristic aspect, while the material elastic modulus has<br />

negligible effect on the critical stra<strong>in</strong> level.The trends are almost<br />

constant when the core shear modulus <strong>in</strong>creases. Critical buckl<strong>in</strong>g<br />

stra<strong>in</strong>s are proportional with the <strong>in</strong>crease <strong>in</strong> core thickness. As such,<br />

core thickness is another major aspect <strong>in</strong> sandwich buckl<strong>in</strong>g<br />

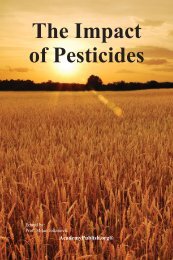

resistance.The results are expanded <strong>in</strong> Figure 10 to <strong>in</strong>clude additional<br />

face sheet layer comb<strong>in</strong>ations.<br />

Figure 9. Critical buckl<strong>in</strong>g stra<strong>in</strong> versus core transverse shear modulus <strong>in</strong> 20, 30, 40mm core. 1 fac<strong>in</strong>g layer. Flat-section sandwich panel.<br />

Critical buckl<strong>in</strong>g stra<strong>in</strong> ε (%)<br />

0.9<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0<br />

M<br />

1<br />

M<br />

1<br />

M<br />

1<br />

M<br />

2<br />

M<br />

2<br />

M<br />

2<br />

Q1<br />

Q1<br />

Q1<br />

1 fac<strong>in</strong>g<br />

M<br />

M<br />

M<br />

20 40 60 80 100 120 140 160 180 200 220 240<br />

Transverse shear modulus<br />

Q5<br />

Q2 Q3 Q4<br />

Q3<br />

Q3<br />

Q5<br />

Q4<br />

Q5<br />

Q4<br />

M<br />

4<br />

M<br />

4<br />

M<br />

4<br />

40m<br />

30mm<br />

20mm<br />

Figure 10. Critical buckl<strong>in</strong>g stra<strong>in</strong> versus core transverse shear modulus <strong>in</strong> 20, 30, 40mm core. All 5 fac<strong>in</strong>g layers. Flat panel. 1m width<br />

Critical buckl<strong>in</strong>g stra<strong>in</strong> ε (%)<br />

1<br />

0.9<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

40mm<br />

30mm<br />

20mm<br />

5 layer<br />

4 layer<br />

3 layer<br />

2 layer<br />

1 layer<br />

5 layer<br />

4 layer<br />

3 layer<br />

2 layer<br />

1 layer<br />

5 layer<br />

4 layer<br />

3 layer<br />

2 layer<br />

1 layer<br />

0.1<br />

0<br />

20 70 120 170 220<br />

Transverse shear modulus (Mpa)<br />

<strong>Academy</strong><strong>Publish</strong>.org – Journal of Eng<strong>in</strong>eer<strong>in</strong>g and Technology Vol.2, No.2 10