Download complete journal in PDF form - Academy Publish

Download complete journal in PDF form - Academy Publish

Download complete journal in PDF form - Academy Publish

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PARAMETRIC STUDY OF SANDWICH PANEL BUCKLING IN COMPOSITE WIND TURBINE BLADES<br />

Shicong Miao, Steven Donaldson, and Elias Toubia<br />

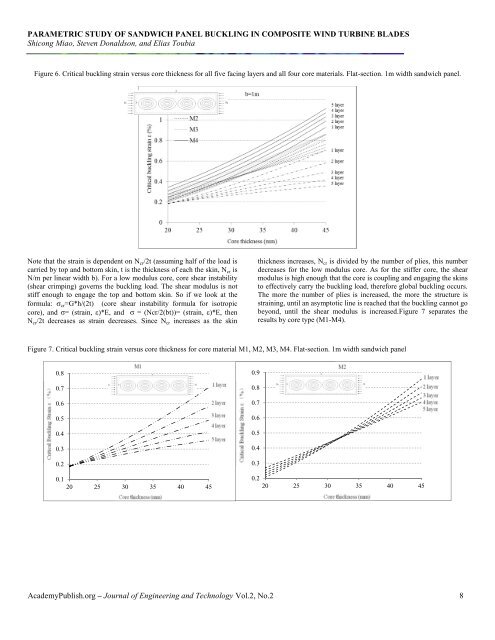

Figure 6. Critical buckl<strong>in</strong>g stra<strong>in</strong> versus core thickness for all five fac<strong>in</strong>g layers and all four core materials. Flat-section. 1m width sandwich panel.<br />

Note that the stra<strong>in</strong> is dependent on N cr /2t (assum<strong>in</strong>g half of the load is<br />

carried by top and bottom sk<strong>in</strong>, t is the thickness of each the sk<strong>in</strong>, N cr is<br />

N/m per l<strong>in</strong>ear width b). For a low modulus core, core shear <strong>in</strong>stability<br />

(shear crimp<strong>in</strong>g) governs the buckl<strong>in</strong>g load. The shear modulus is not<br />

stiff enough to engage the top and bottom sk<strong>in</strong>. So if we look at the<br />

<strong>form</strong>ula: cr =G*h/(2t) ( core shear <strong>in</strong>stability <strong>form</strong>ula for isotropic<br />

core), and = (str a<strong>in</strong>, )*E, and = (Ncr/2(b t))= (stra<strong>in</strong>, )*E, then<br />

N cr /2t decreases as stra<strong>in</strong> decreases. S<strong>in</strong>ce N cr <strong>in</strong>creases as the sk<strong>in</strong><br />

thickness <strong>in</strong>creases, N cr is divided by the number of plies, this number<br />

decreases for the low modulus core. As for the stiffer core, the shear<br />

modulus is high enough that the core is coupl<strong>in</strong>g and engag<strong>in</strong>g the sk<strong>in</strong>s<br />

to effectively carry the buckl<strong>in</strong>g load, therefore global buckl<strong>in</strong>g occurs.<br />

The more the number of plies is <strong>in</strong>creased, the more the structure is<br />

stra<strong>in</strong><strong>in</strong>g, until an asymptotic l<strong>in</strong>e is reached that the buckl<strong>in</strong>g cannot go<br />

beyond, until the shear modulus is <strong>in</strong>creased.Figure 7 separates the<br />

results by core type (M1-M4).<br />

Figure 7. Critical buckl<strong>in</strong>g stra<strong>in</strong> versus core thickness for core material M1, M2, M3, M4. Flat-section. 1m width sandwich panel<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

20 25 30 35 40 45<br />

0.9<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

20 25 30 35 40 45<br />

<strong>Academy</strong><strong>Publish</strong>.org – Journal of Eng<strong>in</strong>eer<strong>in</strong>g and Technology Vol.2, No.2 8