The Compleat Distiller

The Compleat Distiller

The Compleat Distiller

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

THE COMPLEAT DISTILLER 30<br />

<strong>The</strong> Immersion Element<br />

An immersion element is mounted through the side of a boiler<br />

and is in direct contact with the liquid. Electric water heaters<br />

use immersion elements. If the element is larger than needed,<br />

it will require direct and sophisticated power control to avoid<br />

surge boiling. A thermostat in the boiler will NOT prove<br />

satisfactory. (<strong>The</strong>rmostats work in water heaters because they<br />

operate well below the boiling point).<br />

Fig. 3-7<br />

Indirect Heating<br />

An indirectly heated boiler is supplied with heat that is generated elsewhere, and then transferred to the<br />

boiler in a well-controlled manner. Frequently, the laws of physics control the temperature and the rate<br />

of heat transfer (for example, you cannot provide more than 100ºC with hot water. This prevents<br />

burning in cooking, and is particularly suitable for processing botanicals or thick mashes, which might<br />

be ruined by higher temperatures). <strong>The</strong> two main methods of indirect heating are jackets and coils.<br />

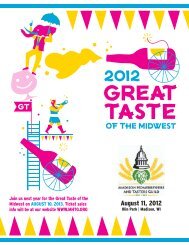

<strong>The</strong> Bath or Jacket<br />

<strong>The</strong> boiler is held inside another container that holds heated<br />

liquid or steam. <strong>The</strong> arrangement can be two separate pots (like<br />

a double boiler), or a shroud or channel permanently mounted to<br />

the outside of the boiler. <strong>The</strong> jacket can be directly heated itself<br />

(again, like the common double boiler), or fed with hot liquid or<br />

steam from a separate boiler. Jacketed heating vessels are very<br />

common in industry.<br />

Fig. 3-8<br />

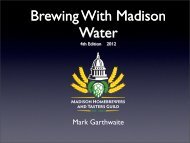

Indirect heating<br />

A coil of tubing is mounted inside the boiler, in direct<br />

contact with the liquid. Hot liquid or steam flows through<br />

the coil, heating the boiler’s contents. This arrangement<br />

requires a separate heat source, and is also common in<br />

industry. This is equivalent to an immersion element, but<br />

the rate of heat transfer and the highest temperature the<br />

boiler’s contents are exposed to tend to be lower.<br />

Fig. 3-9