The Compleat Distiller

The Compleat Distiller

The Compleat Distiller

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

THE COMPLEAT DISTILLER 52<br />

Designing and building stills<br />

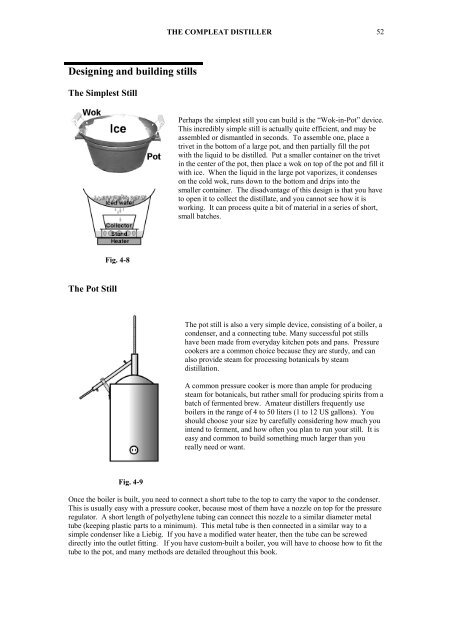

<strong>The</strong> Simplest Still<br />

Perhaps the simplest still you can build is the “Wok-in-Pot” device.<br />

This incredibly simple still is actually quite efficient, and may be<br />

assembled or dismantled in seconds. To assemble one, place a<br />

trivet in the bottom of a large pot, and then partially fill the pot<br />

with the liquid to be distilled. Put a smaller container on the trivet<br />

in the center of the pot, then place a wok on top of the pot and fill it<br />

with ice. When the liquid in the large pot vaporizes, it condenses<br />

on the cold wok, runs down to the bottom and drips into the<br />

smaller container. <strong>The</strong> disadvantage of this design is that you have<br />

to open it to collect the distillate, and you cannot see how it is<br />

working. It can process quite a bit of material in a series of short,<br />

small batches.<br />

Fig. 4-8<br />

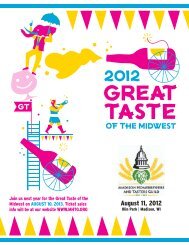

<strong>The</strong> Pot Still<br />

<strong>The</strong> pot still is also a very simple device, consisting of a boiler, a<br />

condenser, and a connecting tube. Many successful pot stills<br />

have been made from everyday kitchen pots and pans. Pressure<br />

cookers are a common choice because they are sturdy, and can<br />

also provide steam for processing botanicals by steam<br />

distillation.<br />

A common pressure cooker is more than ample for producing<br />

steam for botanicals, but rather small for producing spirits from a<br />

batch of fermented brew. Amateur distillers frequently use<br />

boilers in the range of 4 to 50 liters (1 to 12 US gallons). You<br />

should choose your size by carefully considering how much you<br />

intend to ferment, and how often you plan to run your still. It is<br />

easy and common to build something much larger than you<br />

really need or want.<br />

Fig. 4-9<br />

Once the boiler is built, you need to connect a short tube to the top to carry the vapor to the condenser.<br />

This is usually easy with a pressure cooker, because most of them have a nozzle on top for the pressure<br />

regulator. A short length of polyethylene tubing can connect this nozzle to a similar diameter metal<br />

tube (keeping plastic parts to a minimum). This metal tube is then connected in a similar way to a<br />

simple condenser like a Liebig. If you have a modified water heater, then the tube can be screwed<br />

directly into the outlet fitting. If you have custom-built a boiler, you will have to choose how to fit the<br />

tube to the pot, and many methods are detailed throughout this book.