The Compleat Distiller

The Compleat Distiller

The Compleat Distiller

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

THE COMPLEAT DISTILLER 56<br />

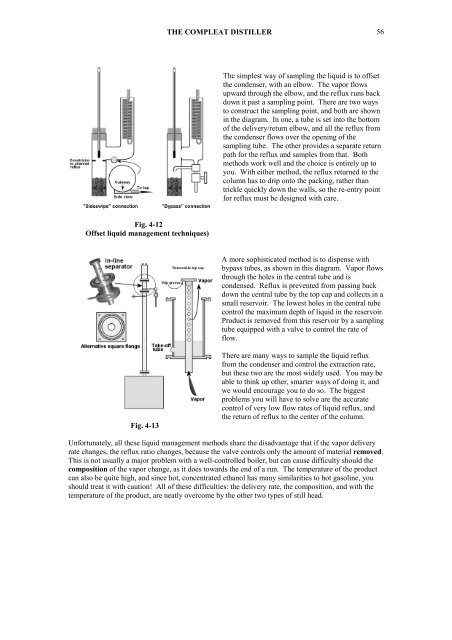

<strong>The</strong> simplest way of sampling the liquid is to offset<br />

the condenser, with an elbow. <strong>The</strong> vapor flows<br />

upward through the elbow, and the reflux runs back<br />

down it past a sampling point. <strong>The</strong>re are two ways<br />

to construct the sampling point, and both are shown<br />

in the diagram. In one, a tube is set into the bottom<br />

of the delivery/return elbow, and all the reflux from<br />

the condenser flows over the opening of the<br />

sampling tube. <strong>The</strong> other provides a separate return<br />

path for the reflux and samples from that. Both<br />

methods work well and the choice is entirely up to<br />

you. With either method, the reflux returned to the<br />

column has to drip onto the packing, rather than<br />

trickle quickly down the walls, so the re-entry point<br />

for reflux must be designed with care.<br />

Fig. 4-12<br />

Offset liquid management techniques)<br />

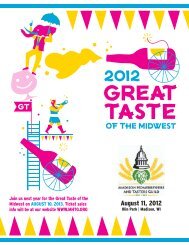

A more sophisticated method is to dispense with<br />

bypass tubes, as shown in this diagram. Vapor flows<br />

through the holes in the central tube and is<br />

condensed. Reflux is prevented from passing back<br />

down the central tube by the top cap and collects in a<br />

small reservoir. <strong>The</strong> lowest holes in the central tube<br />

control the maximum depth of liquid in the reservoir.<br />

Product is removed from this reservoir by a sampling<br />

tube equipped with a valve to control the rate of<br />

flow.<br />

Fig. 4-13<br />

<strong>The</strong>re are many ways to sample the liquid reflux<br />

from the condenser and control the extraction rate,<br />

but these two are the most widely used. You may be<br />

able to think up other, smarter ways of doing it, and<br />

we would encourage you to do so. <strong>The</strong> biggest<br />

problems you will have to solve are the accurate<br />

control of very low flow rates of liquid reflux, and<br />

the return of reflux to the center of the column.<br />

Unfortunately, all these liquid management methods share the disadvantage that if the vapor delivery<br />

rate changes, the reflux ratio changes, because the valve controls only the amount of material removed.<br />

This is not usually a major problem with a well-controlled boiler, but can cause difficulty should the<br />

composition of the vapor change, as it does towards the end of a run. <strong>The</strong> temperature of the product<br />

can also be quite high, and since hot, concentrated ethanol has many similarities to hot gasoline, you<br />

should treat it with caution! All of these difficulties: the delivery rate, the composition, and with the<br />

temperature of the product, are neatly overcome by the other two types of still head.