The Compleat Distiller

The Compleat Distiller

The Compleat Distiller

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

THE COMPLEAT DISTILLER 51<br />

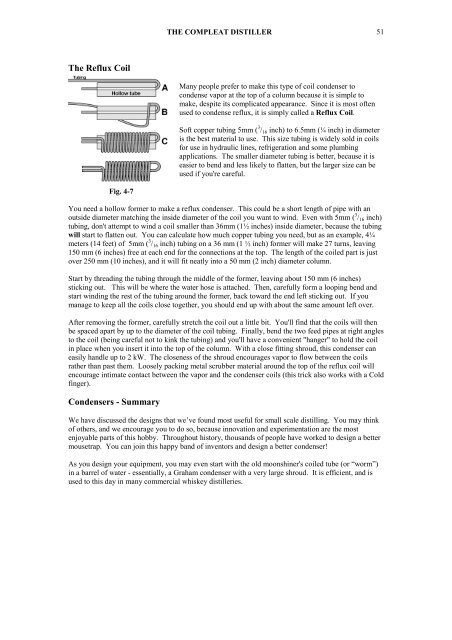

<strong>The</strong> Reflux Coil<br />

Many people prefer to make this type of coil condenser to<br />

condense vapor at the top of a column because it is simple to<br />

make, despite its complicated appearance. Since it is most often<br />

used to condense reflux, it is simply called a Reflux Coil.<br />

Soft copper tubing 5mm ( 3 / 16 inch) to 6.5mm (¼ inch) in diameter<br />

is the best material to use. This size tubing is widely sold in coils<br />

for use in hydraulic lines, refrigeration and some plumbing<br />

applications. <strong>The</strong> smaller diameter tubing is better, because it is<br />

easier to bend and less likely to flatten, but the larger size can be<br />

used if you're careful.<br />

Fig. 4-7<br />

You need a hollow former to make a reflux condenser. This could be a short length of pipe with an<br />

outside diameter matching the inside diameter of the coil you want to wind. Even with 5mm ( 3 / 16 inch)<br />

tubing, don't attempt to wind a coil smaller than 36mm (1½ inches) inside diameter, because the tubing<br />

will start to flatten out. You can calculate how much copper tubing you need, but as an example, 4¼<br />

meters (14 feet) of 5mm ( 3 / 16 inch) tubing on a 36 mm (1 ½ inch) former will make 27 turns, leaving<br />

150 mm (6 inches) free at each end for the connections at the top. <strong>The</strong> length of the coiled part is just<br />

over 250 mm (10 inches), and it will fit neatly into a 50 mm (2 inch) diameter column.<br />

Start by threading the tubing through the middle of the former, leaving about 150 mm (6 inches)<br />

sticking out. This will be where the water hose is attached. <strong>The</strong>n, carefully form a looping bend and<br />

start winding the rest of the tubing around the former, back toward the end left sticking out. If you<br />

manage to keep all the coils close together, you should end up with about the same amount left over.<br />

After removing the former, carefully stretch the coil out a little bit. You'll find that the coils will then<br />

be spaced apart by up to the diameter of the coil tubing. Finally, bend the two feed pipes at right angles<br />

to the coil (being careful not to kink the tubing) and you'll have a convenient "hanger" to hold the coil<br />

in place when you insert it into the top of the column. With a close fitting shroud, this condenser can<br />

easily handle up to 2 kW. <strong>The</strong> closeness of the shroud encourages vapor to flow between the coils<br />

rather than past them. Loosely packing metal scrubber material around the top of the reflux coil will<br />

encourage intimate contact between the vapor and the condenser coils (this trick also works with a Cold<br />

finger).<br />

Condensers - Summary<br />

We have discussed the designs that we’ve found most useful for small scale distilling. You may think<br />

of others, and we encourage you to do so, because innovation and experimentation are the most<br />

enjoyable parts of this hobby. Throughout history, thousands of people have worked to design a better<br />

mousetrap. You can join this happy band of inventors and design a better condenser!<br />

As you design your equipment, you may even start with the old moonshiner's coiled tube (or “worm”)<br />

in a barrel of water - essentially, a Graham condenser with a very large shroud. It is efficient, and is<br />

used to this day in many commercial whiskey distilleries.