The Compleat Distiller

The Compleat Distiller

The Compleat Distiller

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

THE COMPLEAT DISTILLER 36<br />

Types of Still<br />

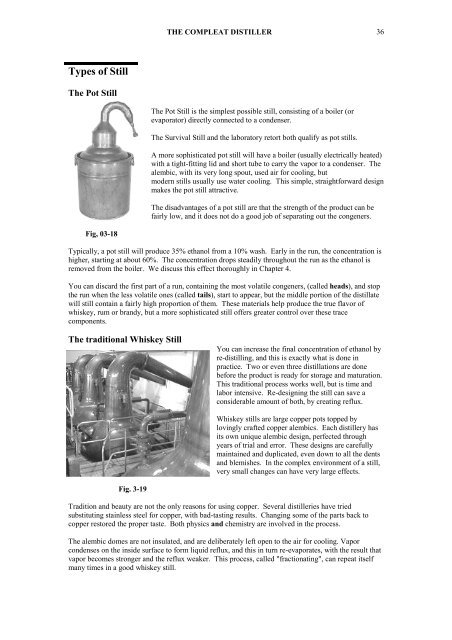

<strong>The</strong> Pot Still<br />

<strong>The</strong> Pot Still is the simplest possible still, consisting of a boiler (or<br />

evaporator) directly connected to a condenser.<br />

<strong>The</strong> Survival Still and the laboratory retort both qualify as pot stills.<br />

A more sophisticated pot still will have a boiler (usually electrically heated)<br />

with a tight-fitting lid and short tube to carry the vapor to a condenser. <strong>The</strong><br />

alembic, with its very long spout, used air for cooling, but<br />

modern stills usually use water cooling. This simple, straightforward design<br />

makes the pot still attractive.<br />

<strong>The</strong> disadvantages of a pot still are that the strength of the product can be<br />

fairly low, and it does not do a good job of separating out the congeners.<br />

Fig, 03-18<br />

Typically, a pot still will produce 35% ethanol from a 10% wash. Early in the run, the concentration is<br />

higher, starting at about 60%. <strong>The</strong> concentration drops steadily throughout the run as the ethanol is<br />

removed from the boiler. We discuss this effect thoroughly in Chapter 4.<br />

You can discard the first part of a run, containing the most volatile congeners, (called heads), and stop<br />

the run when the less volatile ones (called tails), start to appear, but the middle portion of the distillate<br />

will still contain a fairly high proportion of them. <strong>The</strong>se materials help produce the true flavor of<br />

whiskey, rum or brandy, but a more sophisticated still offers greater control over these trace<br />

components.<br />

<strong>The</strong> traditional Whiskey Still<br />

You can increase the final concentration of ethanol by<br />

re-distilling, and this is exactly what is done in<br />

practice. Two or even three distillations are done<br />

before the product is ready for storage and maturation.<br />

This traditional process works well, but is time and<br />

labor intensive. Re-designing the still can save a<br />

considerable amount of both, by creating reflux.<br />

Whiskey stills are large copper pots topped by<br />

lovingly crafted copper alembics. Each distillery has<br />

its own unique alembic design, perfected through<br />

years of trial and error. <strong>The</strong>se designs are carefully<br />

maintained and duplicated, even down to all the dents<br />

and blemishes. In the complex environment of a still,<br />

very small changes can have very large effects.<br />

Fig. 3-19<br />

Tradition and beauty are not the only reasons for using copper. Several distilleries have tried<br />

substituting stainless steel for copper, with bad-tasting results. Changing some of the parts back to<br />

copper restored the proper taste. Both physics and chemistry are involved in the process.<br />

<strong>The</strong> alembic domes are not insulated, and are deliberately left open to the air for cooling. Vapor<br />

condenses on the inside surface to form liquid reflux, and this in turn re-evaporates, with the result that<br />

vapor becomes stronger and the reflux weaker. This process, called "fractionating", can repeat itself<br />

many times in a good whiskey still.