The Compleat Distiller

The Compleat Distiller

The Compleat Distiller

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

THE COMPLEAT DISTILLER 49<br />

Condensers<br />

In Chapter 3, we discussed five important factors of condenser design. <strong>The</strong>y are:<br />

a. <strong>The</strong> area of the cooling surface. If you double the area, you double the heat transfer.<br />

b. <strong>The</strong> thermal resistivity of the condenser material. Again, double this factor and halve the heat<br />

transfer.<br />

c. <strong>The</strong> thickness of the material separating the vapor from the coolant. If you double the thickness,<br />

you halve the heat transfer.<br />

d. Turbulence − the movement of both vapor and cooling medium relative to the cooling surface that<br />

separates them.<br />

e. Usually, you get the best efficiency when vapor and cooling medium run in opposite directions.<br />

We also arrived at a Rule of Thumb:<br />

1 kW of boiler power will raise the temperature of cooling water flowing at 1 liter per minute by<br />

14ºC (26ºF)<br />

<strong>The</strong> molecules of a gas are much further apart than in a liquid, making heat transfer less efficient. It is<br />

possible to pass vapor through a tube or system of tubes and to cool those tubes with air, but it will be<br />

difficult because both materials are gases, and have poor heat transfer characteristics. <strong>The</strong> design of<br />

such a system will have to be quite clever. Car radiators work quite efficiently because the medium<br />

being cooled is a liquid and is in intimate contact with the finned radiator tubing. And on that subject,<br />

if you are contemplating using a car radiator as a condenser for your vapor - DON’T! Car radiators are<br />

generally manufactured with lead solder, and if they have been used, are probably contaminated with<br />

lead from the fuel. You don't want lead to get into your product, because you will be consuming it.<br />

Lead is a very nasty and cumulative poison that builds up in the body.<br />

<strong>The</strong>se factors should be considered when you choose what type and size of condenser you want to<br />

make. Since your requirements may be unique, and different from anyone else’s, any dimensions that<br />

we give are only indicative. Feel free to change them slightly, as your purposes or materials require.<br />

This is the Ideas Department, and the most important ideas are your own!<br />

We discussed the various types of condenser in Chapter 3. Now - how can you make them yourself?<br />

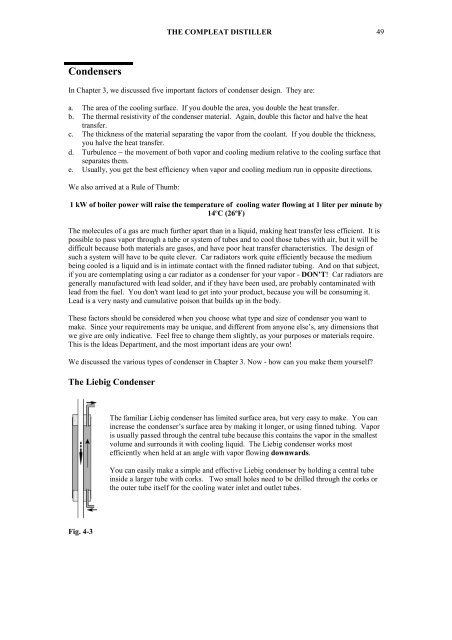

<strong>The</strong> Liebig Condenser<br />

<strong>The</strong> familiar Liebig condenser has limited surface area, but very easy to make. You can<br />

increase the condenser’s surface area by making it longer, or using finned tubing. Vapor<br />

is usually passed through the central tube because this contains the vapor in the smallest<br />

volume and surrounds it with cooling liquid. <strong>The</strong> Liebig condenser works most<br />

efficiently when held at an angle with vapor flowing downwards.<br />

You can easily make a simple and effective Liebig condenser by holding a central tube<br />

inside a larger tube with corks. Two small holes need to be drilled through the corks or<br />

the outer tube itself for the cooling water inlet and outlet tubes.<br />

Fig. 4-3