Download the July/August 2002 Issue in PDF format - Gear ...

Download the July/August 2002 Issue in PDF format - Gear ...

Download the July/August 2002 Issue in PDF format - Gear ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

of lead are usually <strong>in</strong>corporated,<br />

Each l<strong>in</strong>e has<br />

Inmeasur<strong>in</strong>g po<strong>in</strong>ts.<br />

Figure 3 compares data of a tooth flank 'form<br />

measured by boih <strong>the</strong> scann<strong>in</strong>g and po<strong>in</strong>t-to-po<strong>in</strong>t<br />

method. The objective 100111 Hank form has<br />

some wav<strong>in</strong>ess (high-frequency components).<br />

That wav<strong>in</strong>ess was found (0 be <strong>the</strong> ma<strong>in</strong> cause of<br />

unpleasant gear noise, The scann<strong>in</strong>g method, can<br />

detect <strong>the</strong> detail of a tooth flank form. but <strong>the</strong><br />

po<strong>in</strong>t-to-polnt method could not do so.<br />

Two K<strong>in</strong>ds 'Of Method-.S 110 Defme<br />

Reference Tooth Su-.rface<br />

Direct approacf' (Machir"e' setl<strong>in</strong>g base],<br />

Exist<strong>in</strong>g CMMs normally <strong>in</strong>corporate <strong>the</strong> nom<strong>in</strong>al<br />

surface calculated by cutt<strong>in</strong>g mach<strong>in</strong>e sett<strong>in</strong>g<br />

parameters and cutter geometry for both r<strong>in</strong>g gear<br />

and p<strong>in</strong>ion as <strong>the</strong> reference surface to def<strong>in</strong>e tooth<br />

flank: form deviation. It is good <strong>in</strong> practice 1:0<br />

check whe<strong>the</strong>r <strong>the</strong> tooth cutt<strong>in</strong>g i performed CO[-<br />

reetly 01' not. But hypoid gears are heat treated,<br />

usually case hardened, and <strong>the</strong>n lapped. Aller<br />

heat treatment or lapp<strong>in</strong>g. tooth surfaces are distorted<br />

or deformed from that of <strong>the</strong> cutt<strong>in</strong>g stage,<br />

That mean gears have lost <strong>the</strong>ir datum and it is<br />

<strong>the</strong>refore often not useful to mea lire <strong>the</strong> tooth<br />

flank form deviation of hypoid gears accord<strong>in</strong>g to<br />

<strong>the</strong> reference based on We mach<strong>in</strong>e sett<strong>in</strong>g.<br />

Conjugate app.roach. In <strong>the</strong> case of <strong>the</strong> scann<strong>in</strong>g<br />

method. <strong>the</strong> reference tooth surface of r<strong>in</strong>g<br />

gears is calculated by cutt<strong>in</strong>g mach<strong>in</strong>e sett<strong>in</strong>g<br />

parameters just like tile former case ..However, for<br />

<strong>the</strong> p<strong>in</strong>ion, <strong>the</strong> conjugate surface to <strong>the</strong> r<strong>in</strong>g gear<br />

urface i u ed, Inthis case, two reference surfaces<br />

can rotate <strong>the</strong>oretically without motion<br />

error.<br />

The conjugate surface of <strong>the</strong> p<strong>in</strong>ion i a virtuaJ<br />

one. If l1Iep<strong>in</strong>ion and gear teeth are measured<br />

5.5 fz component<br />

IOrd.r tQllb mesb<strong>in</strong>g '1rI!1(!!!mcy<br />

us<strong>in</strong>g such a conjugate approach. <strong>the</strong> measured Tooth Contact Anal,ysis Under No Load<br />

values of <strong>the</strong> flank form deviation would show Conventionally. tooth contact a.naJysis (TCA)<br />

how far <strong>the</strong> form is from its true surface. which of hypoid gear is performed us<strong>in</strong>g tooth surface<br />

would realize conjugate motion. Tile same is true geometry calculated by <strong>the</strong> tooth cutt<strong>in</strong>g mach<strong>in</strong>e<br />

,j'I'~"... ,...<br />

i..".... .r....... '\<br />

F •So.., .. olll'P .ib~<br />

- i"1 ... ,b:mpla o1 l lnullil~lti..<br />

,...4<br />

./ BySClnn<strong>in</strong>g rTJiI.sur<strong>in</strong>liimM;hi."<br />

,I) M,ul!rd res!!1101 vibration bllMeasu:rd curn ollootll "ID~:form<br />

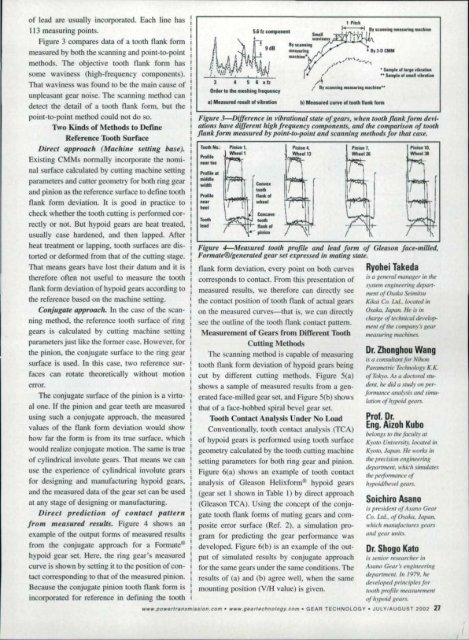

Figure 3-Difjerence ill vibrational stale oj gears, IIIlIel.' tootll,jlallkjorm de vialUms<br />

base dlfjert!flt high frequency ,componelll • alld tile comparo.'Oll 0/ tootll<br />

fll1II1c/ormmeasured by poirlt-to-poillt "",d. canllirlg mel/mas/or ,'I,al ca_I!.<br />

Pr.m.<br />

nl., tOI<br />

Pnlfl'-I!'<br />

.ifd_,<br />

·widtbl<br />

Prom.<br />

I!U!11<br />

IhRI<br />

P<strong>in</strong>iQo1.<br />

W-h •• ll<br />

of cyl<strong>in</strong>drical <strong>in</strong>volute gears. That mean we can sett<strong>in</strong>g parameters for bothr:<strong>in</strong>g gear and p<strong>in</strong>ion.<br />

use <strong>the</strong> experience of cyl<strong>in</strong>drical <strong>in</strong>volute gears Figure 6(a) hews an example of tooth contact<br />

for design<strong>in</strong>g and manufactur<strong>in</strong>g hypoidgears, analy is of Gleason Hehxform® hypoid gears<br />

and <strong>the</strong> measured data of <strong>the</strong> gear el can be used (gear et 1 shown <strong>in</strong> Table I) by direct approach<br />

at any stage of design<strong>in</strong>g or manufactur<strong>in</strong>g. (Gleason TCA). Us<strong>in</strong>g <strong>the</strong> concept of <strong>the</strong> conjuis<br />

president<br />

of Asmlo <strong>Gear</strong><br />

Direct' pred.iclioll of contact pat.tern gate tooth flank forms of mat<strong>in</strong>g gears and com- Co. ua.. of Osaka. Japan.<br />

from measured reslIlts. Figure 4 shows an po ite error surface (Ref. 2). a simulation pro- which manufactures Mears<br />

example of <strong>the</strong> output forms of measured results gram for predict<strong>in</strong>g <strong>the</strong> gear performance was and gear unhs.<br />

from <strong>the</strong> conjugate approach for a Forma!.e® developed. Figure 6(b) is an example of <strong>the</strong> out- Dr; Shogo Kato<br />

hypoidgear set. Here, <strong>the</strong> r<strong>in</strong>g gear's measured put of simulated results by conjugate approach I.r senior 1'f'.W!IJr'C'h('r ill<br />

curve i hown by sen<strong>in</strong>git to <strong>the</strong> po Won of coo- for <strong>the</strong> same gears under tile same condition. The Asalla <strong>Gear</strong>'s eIIR;t1eer;'lg<br />

department. 1/1 1979. he<br />

tact correspond<strong>in</strong>g to thaI of <strong>the</strong> measured p<strong>in</strong>ion. results of (a) and. (b) agree well, when <strong>the</strong> same<br />

lie veloped pr<strong>in</strong>ciples for<br />

Because <strong>the</strong> conjugate p<strong>in</strong>ion: tooth flank form is mount<strong>in</strong>g position (VIH valuerts given. 1001/1 profile m1.'fISIIYI.'m1'11I<br />

<strong>in</strong>corporated for reference <strong>in</strong> def<strong>in</strong><strong>in</strong>g <strong>the</strong> tooth of hypoiti gears.<br />

www.powerl,ansmlssion.com •.. W .... gfN.,rschnology.com '. GEAR TECHNOLOGY' JULY/AUGUST <strong>2002</strong> .27<br />

~nr!! __•<br />

1•• 1b<br />

".nk ,Dr<br />

wh •• r<br />

ICooe ...<br />

loath<br />

;F:...::.,,:lrltt- 'It,nk 0'<br />

pl.lo.<br />

P,<strong>in</strong>ion t,<br />

Wh •• 11]<br />

Figur:e 4-Measul'ed tooti. profill! alld teod [ormo[ Gleason jace-milled,<br />

Fiirmale@lgenerated gear set expressed ;n malill,g state.<br />

see <strong>the</strong> outl<strong>in</strong>e of <strong>the</strong> tooth flank contact pattern.<br />

Measurement of <strong>Gear</strong>s from DLfIcR!ol Tooth<br />

Cutt<strong>in</strong>g Methods<br />

The scann<strong>in</strong>g method is capable of measur<strong>in</strong>g<br />

tooth flank form deviation of hypoid gear be<strong>in</strong>g<br />

cut by different cutt<strong>in</strong>g methods, igure 5(a)<br />

shows a sample of measured results (rom a generated<br />

face-milled gear set. and Figure 5(b) shows<br />

that of a face-bobbed spiral bevelgear set.<br />

Ryohei Takedal<br />

flank form deviation, every po.<strong>in</strong>l on both curves<br />

. f is {/ general manager ill rile<br />

corresponds to contact. From this presentation or<br />

system eng<strong>in</strong>eer<strong>in</strong>g dept/rimea<br />

ured re ul • we <strong>the</strong>refore can directly see i1If'!l! (if Osako Seimil.fll<br />

<strong>the</strong> contact position of tooth flank of actual gears Kiwi Co. Ltd .. Jocml'd ill<br />

on <strong>the</strong> measured curves=that is. we can directly Osaka. Japo». HI' is ill<br />

ciJarge of technical del·elop·<br />

melll nJ <strong>the</strong> ('atfl{)(.III_~1$ sear<br />

measur<strong>in</strong>g mach<strong>in</strong>es.<br />

Dr. Zhonghou<br />

w.ang<br />

i.f a consultant for Nihon<br />

Parametric Technology I(.K.<br />

of Tokyo. As (l doctoral studau.<br />

Ire did a Sillily on perfonnance<br />

anotysis ana simu-<br />

/mimr of ttypoid Rears.<br />

Prof. Dr.<br />

Eng ..Aizoh Kl.lbol<br />

belol1gs to tht! jacullY at<br />

Kyoto Univer. iry, 1£l{'alt!d ill<br />

Kyoto. Japan. He 'l'or.b <strong>in</strong><br />

<strong>the</strong> precision eng<strong>in</strong>eerillg<br />

deportment. w/rk/l.l<strong>in</strong>rll/ares<br />

tlu: lJeifomrance of<br />

In·IJUidlbel·e/ gems.