Download the July/August 2002 Issue in PDF format - Gear ...

Download the July/August 2002 Issue in PDF format - Gear ...

Download the July/August 2002 Issue in PDF format - Gear ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1<br />

G<br />

1<br />

"<br />

• 1 TECHNOLOGY FOCUS<br />

M'i<strong>in</strong>'imizatioln of <strong>in</strong>-Process<br />

Corrosion of Aerospace <strong>Gear</strong>s<br />

Son 'Ng!uyen, .AI:i Manesh. Jim~ Reeves and Danny Mahan<br />

I<br />

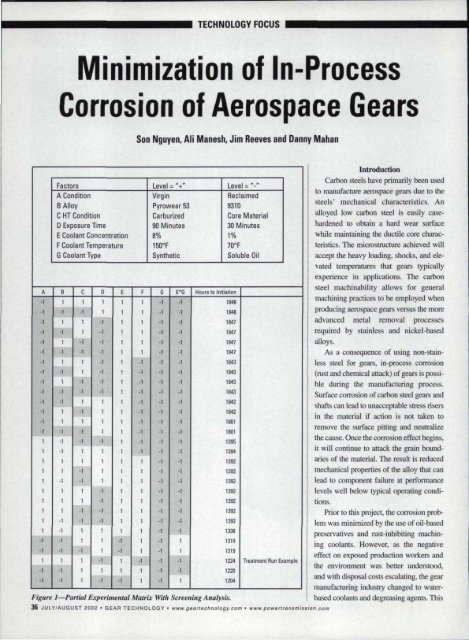

Factors Level = "+"<br />

U<br />

Level =<br />

I<br />

A Condition Virg<strong>in</strong> Heclaimed<br />

I B Alloy Pyrowear 53 9310<br />

C HT Condition Carburized Core Materia.1<br />

I<br />

o Exposure Time 90 M<strong>in</strong>utes 30 M<strong>in</strong>utes<br />

I<br />

E Coolant Concentration 8% 1%<br />

F Coolant Temperature 150°F iO°F<br />

I G Coolant Type Syn<strong>the</strong>tic Soluble Oil<br />

A B C 0 E F<br />

1<br />

,<br />

·1 1 1 1 1<br />

·1 ·1 ·1 1 , ,<br />

,<br />

E"G I Hours to Initiation i<br />

., ., 1848 II<br />

., ., 1848<br />

! I<br />

I -1 1 I 1 I -1 -, -,<br />

! '847<br />

I<br />

I<br />

I ·1 -1 I 1 I ·1 -t .,<br />

'841<br />

., I<br />

1 --:;-1 ·1 , -, -, '841<br />

·1 ., -, ., ,<br />

I 1 -1 ., 1847<br />

-, ,<br />

,<br />

I -I 1 ., -1 -, 1843<br />

.,<br />

!<br />

-, 1 -t 1 -, -1 -, 1843<br />

-1<br />

I<br />

I<br />

I ' -,<br />

1-<br />

-, I<br />

1 -1 -1 -, 1843<br />

·1 ·1 -1 -r 1 ., -, -I '843<br />

I-<br />

-t -I 1<br />

,<br />

1 -1 .,<br />

i<br />

I<br />

-t 1842<br />

-1 I ., 1 1 ·1 -1 I -1 1842<br />

:<br />

·1 1 I 1 1 ·1 ·1 ·1 'BOI<br />

·1 -, ·1 1 1 ·1 -1 ·1 18nt<br />

1 -1 ·1 ., 1 ·1 ·1 ., 1395 ,I I<br />

1 ·1 1 1 , -, ., ·1 1394 I<br />

I 1 1 1<br />

,<br />

1 I 1 ·1 .,<br />

I<br />

I<br />

1392<br />

I-<br />

1 1 ·1 1 1<br />

, I -, ·1 1392<br />

i I ., ·1<br />

, , 1 1 -, ., 1392<br />

I<br />

I I-<br />

I I 1 1 -1 ,<br />

1 -, ., 1392 I<br />

I<br />

I<br />

I<br />

1 1 1 -1 1 1 -, -1 1392<br />

I--~' !<br />

1 1 -t -1 ,<br />

1 -t ·1 1392<br />

I 1 -1 -t -1 1 1 -I -1 1392<br />

I<br />

I<br />

I<br />

I<br />

1 -I 1 1 1 1 ·1 -, 1338<br />

I<br />

-1 -1 1 1 , -1 1 -1 I 1 1319 I<br />

I<br />

I<br />

·1 ·1 ·1 1 ·1 1 ., 1 1319<br />

I<br />

I<br />

1 1 1 ·1 1 .,<br />

I ·1 -1 1224 : Treatment Run Example I<br />

.,<br />

,<br />

·1 1 1 1 1 I ·1 -1 1220 I<br />

I<br />

., ·1 1 ·1 ·1 1 I ·1 1 1204 ;<br />

i<br />

Figure i-Partial Experimental Matrix With Screen <strong>in</strong>g<br />

Analy<br />

sis.<br />

36 JULY/AUGUST <strong>2002</strong> .' GEAR TECHNOLOGY" www.qe srtecnnotoqv.com » www.powerrransmission ..ccm<br />

,<br />

I<br />

i<br />

I<br />

1<br />

Intrnduction<br />

Carbon steels have primarily been used<br />

to manufacture aerospace gears due to <strong>the</strong><br />

steels' mechanical characteristics. An<br />

alloyed low carbon steel is easily casehardened<br />

to obta<strong>in</strong> a hard wear surface<br />

while ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g <strong>the</strong> ductile core characteristics.<br />

The microstructure achieved will<br />

accept <strong>the</strong> heavy load<strong>in</strong>g. shocks, and elevated<br />

temperatures that gears typically<br />

experience <strong>in</strong> applications. The carbon<br />

steel mach<strong>in</strong>ability allows for general<br />

mach<strong>in</strong><strong>in</strong>g practices to be employed when<br />

produc<strong>in</strong>g aerospace gears versus <strong>the</strong> more<br />

advanced metal removal processes<br />

required by sta<strong>in</strong>less and nickel-based<br />

alloys.<br />

As a consequence<br />

of us<strong>in</strong>g non-sta<strong>in</strong>less<br />

steel for gears, <strong>in</strong>-process corrosion<br />

(rust and chemical attack) of gears is possible<br />

dur<strong>in</strong>g <strong>the</strong> manufactur<strong>in</strong>g process.<br />

Surface corrosion of carbon steel gears and<br />

shafts can lead to unacceptable stress risers<br />

<strong>in</strong> <strong>the</strong> material if action is not taken to<br />

remove <strong>the</strong> surface pitt<strong>in</strong>g and neutralize<br />

<strong>the</strong> cause. Once <strong>the</strong> corrosion effect beg<strong>in</strong>s,<br />

it wilLI cont<strong>in</strong>ue to attack <strong>the</strong> gra<strong>in</strong> boundaries<br />

of <strong>the</strong> material. The result is reduced<br />

mechanical properties of <strong>the</strong> alloy that can<br />

lead to component failure at performance<br />

levels wel.lbelow typical operat<strong>in</strong>g conditions.<br />

Prior to this project. <strong>the</strong> corrosion problem<br />

was m<strong>in</strong>imized by <strong>the</strong> use of oil-based<br />

preservatives and rust-<strong>in</strong>hibit<strong>in</strong>g mach<strong>in</strong><strong>in</strong>g<br />

coolants. However, as <strong>the</strong> negative<br />

effect on exposed production workers and<br />

<strong>the</strong> environment was better understood,<br />

and with disposal costs escalat<strong>in</strong>g, <strong>the</strong> gear<br />

manufactur<strong>in</strong>g <strong>in</strong>dustry changed to waterbased<br />

coolants and degreas<strong>in</strong>gagents. This