Download the July/August 2002 Issue in PDF format - Gear ...

Download the July/August 2002 Issue in PDF format - Gear ...

Download the July/August 2002 Issue in PDF format - Gear ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

al·GI.....<br />

~f<br />

~lLJ<br />

'.::<br />

No,. 01 teeth:<br />

\ tll,l'll<br />

~ M':!~I.'<br />

,,~ hce Width:<br />

".lV· : 25.0mm<br />

.. P<strong>in</strong>ion Ofbet<br />

_ 5jt mill<br />

"<strong>in</strong>al •• at PLniQP<br />

:gan.raled/generated hnoid gelt<br />

p...m.<br />

r••!fiLud<br />

''li-i"'tr.<br />

" \<br />

Figure 5 Measured tooth ./klnk form of gears of different cutt<strong>in</strong>g met/JOds.<br />

Tooth contllc': pattern<br />

!Motion CUIflI8<br />

-.,..... _',L--<br />

Vill., ..IJ.~1.13 (mm)<br />

a) Direct appr,olch (Gleason TCA)<br />

Figure 6-TCA<br />

.::.,<br />

r.,l,\~~ ....<br />

1/.: ~;"<br />

'If! ~<br />

it<br />

C~ntaclP.lttem<br />

1"--- ... -<br />

! j TraR.mission Errllf<br />

j __ M~~<br />

AI. <strong>the</strong> first stage of hypoid<br />

cutt<strong>in</strong>g<br />

28 JULY/AUGUST <strong>2002</strong>· GEAR TECHNOLOGV • www.geartschnology.com' wwW.powsftransm/ss/on.com<br />

..<br />

~ liiim~':J;<br />

! u - -<br />

• --':11 !I' -, -<br />

-------'<br />

ViIl,= ..1),081'1.'13 (mm)<br />

of direct approach amI conjugaleappr:oach.<br />

.,<br />

..<br />

..<br />

..<br />

..<br />

Contac! Pattern & Plm 01ColIIId<br />

., ; II<br />

J J<br />

/"<br />

r /<br />

of F F<br />

... ..<br />

"<br />

fI Trusm'ission' Enor<br />

(Too.h Harmonics)<br />

u<br />

IJ<br />

u<br />

u<br />

u<br />

1-'<br />

.....-<br />

OJ •<br />

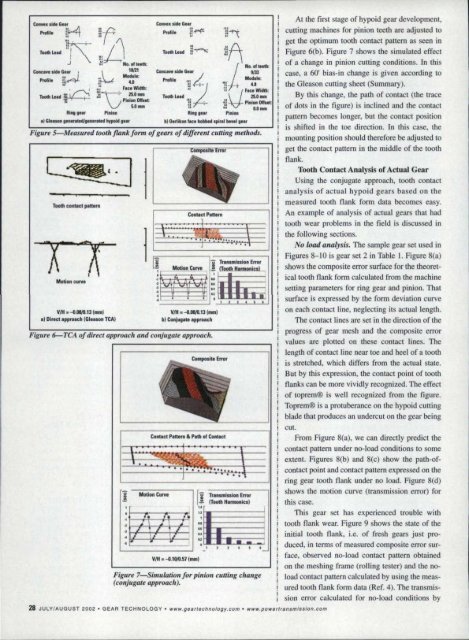

Figure "" Simuiatio.n! for pillio/l CUttilig ehang«<br />

(conjugate approacll).<br />

I<br />

gear development,<br />

mach<strong>in</strong>es for p<strong>in</strong>ion teeth are adjusted to<br />

get <strong>the</strong> optimum tooth contact pattern as seen <strong>in</strong><br />

Figure 6(b). Figure 7 shows <strong>the</strong> simulated effect<br />

of a change <strong>in</strong> p<strong>in</strong>ion cutt<strong>in</strong>g conditions. In this<br />

case, a 60' bias-<strong>in</strong> change is given accord<strong>in</strong>g to'<br />

<strong>the</strong> Gleason cutt<strong>in</strong>g sheet (Summary).<br />

By this change, <strong>the</strong> path of contact (<strong>the</strong> trace<br />

of dots <strong>in</strong> <strong>the</strong> figure) is <strong>in</strong>cl<strong>in</strong>ed and <strong>the</strong> contact<br />

pattern becomes longer, but <strong>the</strong> contact position<br />

is shifted <strong>in</strong> <strong>the</strong> toe direction .. In this case, <strong>the</strong><br />

mount<strong>in</strong>g position should <strong>the</strong>refore be adjusted to<br />

get <strong>the</strong> contact. pattern. <strong>in</strong> <strong>the</strong> middle<br />

of <strong>the</strong> moth<br />

Hank.<br />

Tooth Contact Analysis of Actual <strong>Gear</strong><br />

Us<strong>in</strong>g <strong>the</strong> conjugate approach, tooth contact<br />

analysis of actual hypcid gears based on <strong>the</strong><br />

measured tooth flank form data becomes easy.<br />

An example of analysis of acrualgears that had<br />

tooth wear problems <strong>in</strong> <strong>the</strong> field is discussed <strong>in</strong><br />

<strong>the</strong> fol1ow<strong>in</strong>g sections.<br />

No load analysis. The sample<br />

gear set used<strong>in</strong><br />

Figures 8-10 is gear set 2 il] Table 1. Figure 8(a)<br />

shows <strong>the</strong> composite error surface for <strong>the</strong> <strong>the</strong>oretical<br />

tooth flank form calculated<br />

from. <strong>the</strong> mach<strong>in</strong>e<br />

sett<strong>in</strong>g parameters for r<strong>in</strong>g gear and p<strong>in</strong>ion. That<br />

surface is expressed by <strong>the</strong> form deviation curve<br />

on each contact l<strong>in</strong>e, neglect<strong>in</strong>g its actual length.<br />

The contact l<strong>in</strong>es are set <strong>in</strong> <strong>the</strong> direction of <strong>the</strong><br />

progress of gear mesh and <strong>the</strong> composite error<br />

values are plotted on <strong>the</strong>se contact l<strong>in</strong>es. The<br />

length of contact l<strong>in</strong>e near toe and heel of a tooth<br />

is stretched, which differs from <strong>the</strong> actual state ..<br />

But by this expression, <strong>the</strong> contact po<strong>in</strong>t of tooth<br />

flanks can be more vividly recognized. The effect<br />

of toprem® is well recognized from <strong>the</strong> figure ..<br />

Toprem® is a protuberance on <strong>the</strong> hypoid cutt<strong>in</strong>g<br />

blade that produces an undercut on <strong>the</strong> gear be<strong>in</strong>g<br />

cut.<br />

FCQm Figure 8(a), we can directlypredict <strong>the</strong><br />

contact pattern under no-load conditions to some<br />

extent, Figures 8(b) and 8(c) show <strong>the</strong> path-ofcontactpe<strong>in</strong>t<br />

and contact pattem expressed on <strong>the</strong><br />

r<strong>in</strong>g gear tooth flank under no load. Figure 8Cd)<br />

shows <strong>the</strong> motion curve (transmission error) for<br />

this case,<br />

This gear set has experienced trouble with<br />

tooth flank wear. Figure '9 shows <strong>the</strong> state of <strong>the</strong><br />

<strong>in</strong>itial tooth flank, l.e. of fresh gears just produced,<br />

<strong>in</strong> terms of measured composite error surface,<br />

observed no-load contact pattern obta<strong>in</strong>ed<br />

on <strong>the</strong> mesh<strong>in</strong>g frame (roll<strong>in</strong>g tester) and<strong>the</strong> noload<br />

contact pa:ttern calculated by us<strong>in</strong>g <strong>the</strong> measured<br />

tooth flank form data (Ref. 4). The transmission<br />

error calculated for no-load conditions by