Boxoffice_May.09.1960

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

BASIC REQUIREMENTS FOR<br />

BETTER PROJECTION<br />

A Review of Maintenance Procedures<br />

I<br />

To Keep Equipment in<br />

Top Condition<br />

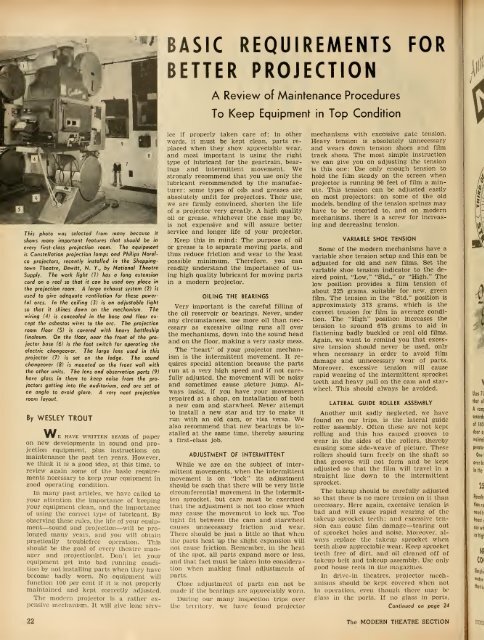

This photo was selected from many because it<br />

shows many important features that should be in<br />

every first-class projection room. The equipment<br />

is Constellation projection lamps and Philips Norelco<br />

projectors, recently installed in the Shoppingtown<br />

Theatre, Dewitt, N. Y., by National Theatre<br />

Supply. The work light (I) has a long extension<br />

cord on a reel so that it can be used any place in<br />

the projection room. A large exhaust system (2) is<br />

used to give adequate ventilation for these powerful<br />

arcs. In the ceiling (3) is an adjustable light<br />

so that it shines down on the mechanism. The<br />

wiring (4) is concealed in the base and floor except<br />

the asbestos wires to the arc. The projection<br />

room floor (5) is covered with heavy battleship<br />

linoleum. On the floor, near the front of the projector<br />

base (6) is the foot switch for operating the<br />

electric changeover. The large lens used in this<br />

projector (7) is set on the ledge. The sound<br />

changeover (8) is mounted on the front wall with<br />

the other units. The lens and observation ports (9)<br />

have glass in them to keep noise from the projectors<br />

getting into the auditorium, and are set at<br />

an angle to avoid glare. A very neat projection<br />

room layout.<br />

By<br />

WESLEY TROUT<br />

w.E HAVE WRITTEN REAMS Of papCl"<br />

on new developments in sound and projection<br />

equipment, plus instructions on<br />

maintenance the past ten years. However,<br />

we think it is a good idea, at this time, to<br />

review again some of the basic requirements<br />

necessary to keep your equipment in<br />

good operating condition.<br />

In many past articles, we have called to<br />

your attention the importance of keeping<br />

your equipment clean, and the importance<br />

of using the correct type of lubricant. By<br />

observing these rules, the life of your equipment—sound<br />

and projection— will be prolonged<br />

many years, and you will obtain<br />

practically troublefree operation. This<br />

.should be the goal of every theatre manager<br />

and projectionist. Don't let your<br />

equipment get into bad running condition<br />

by not installing parts when they have<br />

become badly worn. No equipment will<br />

function 100 per cent if it is not properly<br />

maintained and kept correctly adjusted.<br />

The modern projector is a rather expensive<br />

mechanism. It will give long serv-<br />

ice if properly taken care of: in other<br />

words, it must be kept clean, parts replaced<br />

when they show appreciable wear,<br />

and most important is using the right<br />

type of lubricant for the geartrain, bearings<br />

and intermittent movement. We<br />

strongly recommend that you use only the<br />

lubricant recommended by the manufacturer:<br />

some types of oils and greases are<br />

absolutely unfit for projectors. Their use.<br />

we are firmly convinced, shorten the life<br />

of a projector very greatly. A high quality<br />

oil or grease, whichever the case may be,<br />

is not expensive and will assure better<br />

service and longer life of your projector.<br />

Keep this in mind: The purpose of oil<br />

or grease is to separate moving parts, and<br />

thus reduce friction and wear to the least<br />

possible minimum. Therefore, you can<br />

readily understand the importance of using<br />

high quality lubricant for moving parts<br />

in a modern projector.<br />

OILING THE<br />

BEARINGS<br />

Very important is the careful filling of<br />

the oil reservoir or bearings. Never, under<br />

any circumstances, use more oil than necessary<br />

as excessive oiling runs all over<br />

the mechanisms, down into the sound head<br />

and on the floor, making a very nasty mess.<br />

The "heart" of your projector mechanism<br />

is the intermittent movement. It requires<br />

special attention because the parts<br />

run at a very high speed and if not carefully<br />

adjusted, the movement will be noisy<br />

and sometimes cause picture jump. Always<br />

insist, if you have your movement<br />

repaired at a shop, on installation of both<br />

a new cam and starwheel. Never attempt<br />

to install a new star and try to make it<br />

run with an old cam, or visa versa. We<br />

also recommend that new bearings be installed<br />

at the same time, thereby assuring<br />

a first-class job.<br />

ADJUSTMENT OF<br />

INTERMITTENT<br />

While we are on the subject of intermittent<br />

movements, when the intermittent<br />

movement is on "lock" its adjustment<br />

should be such that there will be very little<br />

circumferential movement in the intermitten<br />

sprocket, but care must be exercised<br />

that the adjustment is not too close which<br />

may cause the movement to lock up. Too<br />

tight fit between the cam and starwheel<br />

causes unnecessary friction and wear.<br />

There should be just a little so that when<br />

the parts heat up the slight expansion will<br />

not cause friction. Remember, in the heat<br />

of the spot, all parts expand more or less,<br />

and that fact must be taken into consideration<br />

when making final adjustments of<br />

parts.<br />

Close adjustment of parts can not be<br />

made if the bearings are appreciably worn.<br />

During our many inspection trips over<br />

the territory, we have found projector<br />

mechanisms with excessive gate tension.<br />

Heavy tension is absolutely unnecessary<br />

and wears down tension shoes and film<br />

track shoes. The most simple instruction<br />

we can give you on adjusting the tension<br />

is this one: Use only enough tension to<br />

hold the film steady on the screen when<br />

projector is running 90 feet of film a minute.<br />

This tension can be adjusted easily<br />

on most projectors: on some of the old<br />

models, bending of the tension springs may<br />

have to be resorted to, and on modern<br />

mechanisms, there is a screw for increasing<br />

and decreasing tension.<br />

VARIABLE SHOE TENSION<br />

Some of the modern mechanisms have a<br />

variable shoe tension setup and this can be<br />

adjusted for old and new films. Set the<br />

variable shoe tension indicator to the desired<br />

point, "Low," "Std.," or "High." The<br />

low position provides a film tension of<br />

about 225 grams, suitable for new, green<br />

film. The tension in the "Std." position is<br />

approximately 373 grams, which is the<br />

correct tension for film in average condition.<br />

The "High" position increases the<br />

tension to around 675 grams to aid in<br />

flattening badly buckled or real old films.<br />

Again, we want to remind you that excessive<br />

tension should never be used, only<br />

when necessary in order to avoid film<br />

damage and unnecessary wear of parts.<br />

Moreover, excessive tension will cause<br />

rapid wearing of the intermittent sprocket<br />

teeth and heavy pull on the cam and starwheel.<br />

This should always be avoided.<br />

LATERAL GUIDE ROLLER ASSEMBLY<br />

Another unit sadly neglected, we have<br />

found on our trips, is the lateral guide<br />

roller assembly. Often these are not kept<br />

rolling and this has caused grooves to<br />

wear in the sides of the rollers, thereby<br />

causing some side-weave of picture. These<br />

rollers should turn freely on the shaft so<br />

that grooves will not form and be kept<br />

adjusted so that the film will travel in a<br />

straight line down to the intermittent<br />

sprocket.<br />

The takeup should be carefully adjusted<br />

so that there is no more tension on it than<br />

necessary. Here again, excessive tension is<br />

bad and will cause rapid wearing of the<br />

takeup sprocket teeth: and excessive tension<br />

can cause film damage— tearing out<br />

of sprocket holes and noise. Moreover, always<br />

replace the takeup sprocket when<br />

teeth show appreciable wear. Keep sprocket<br />

teeth free of dirt, and oil cleaned off of<br />

takeup belt and takeup assembly. Use only<br />

good house reels in the magazines.<br />

In drive-in theatres, projector mechanisms<br />

should be kept covered when not<br />

in operation, even though there may be<br />

glass in the ports. If no glass in ports.<br />

Continued on page 24<br />

22<br />

The<br />

MODERN THEATRE SECTION