- Page 1 and 2:

y TABLE OF CONTENTS GENERAL........

- Page 3 and 4:

y 1.47.2 Expendable Materials .....

- Page 5 and 6:

y 2.33 EXCAVATION & BACKFILLING OF

- Page 7 and 8:

y 5.11.9 Aggregate Testing ........

- Page 9 and 10:

y 11.2.2 Steel.....................

- Page 11 and 12:

y 14.11 GLAZING TO WOOD - WITH BEAD

- Page 13 and 14:

y 18.6.10.1 Gradation Control unit.

- Page 15 and 16:

y 20.4.1.5 Setting-Out ............

- Page 17 and 18:

y 1 GENERAL 1.1 Scope of Work The w

- Page 19 and 20:

y 1.5 Units of Measurement and Abbr

- Page 21 and 22:

y Such approval, however, will not

- Page 23 and 24:

y The Engineer may check all or any

- Page 25 and 26:

y The Contractor shall be held sole

- Page 27 and 28:

1.23 Customs and Local Dues y All s

- Page 29 and 30:

y dewatering plant that may be nece

- Page 31 and 32:

y 1.34 Road Crossing Road crossing

- Page 33 and 34:

1.39 Cooperation with Other Contrac

- Page 35 and 36:

y 1.46 Site Office for the Engineer

- Page 37 and 38:

y SCHEDULE OF OFFICES The office re

- Page 39 and 40:

y Works and interpreting any inform

- Page 41 and 42:

j. Survey arrows, wooden pegs, nail

- Page 43 and 44:

y Materials Frequency Relevant Stan

- Page 45 and 46:

Materials Frequency Relevant Standa

- Page 47 and 48:

y 1.49.2 Standard Sampling Methods

- Page 49 and 50:

y Materials Frequency Standard Samp

- Page 51 and 52:

y Materials Frequency Standard Samp

- Page 53 and 54:

y 2 EARTH WORK 2.1 Scope of Work Th

- Page 55 and 56:

y If damage to existing utilities c

- Page 57 and 58:

y approved material and compacted b

- Page 59 and 60:

y material and shall provide a clea

- Page 61 and 62:

y as shown on the drawings or other

- Page 63 and 64:

2. Methods used for stockpiling gra

- Page 65 and 66:

y completion of such tests, the bac

- Page 67 and 68:

y When the embankment material resu

- Page 69 and 70:

y Embankments, which are formed of

- Page 71 and 72:

y All accepted subgrade preparation

- Page 73 and 74:

y Plasticity Index AASHTO T90 6% ma

- Page 75 and 76:

y Aggregate Base will be measured b

- Page 77 and 78:

y roadbase shall be maintained in a

- Page 79 and 80:

y 2.29 Dikes of Guiding Dams 2.29.1

- Page 81 and 82:

2.31.4 Measurement y Box Gabions wi

- Page 83 and 84:

y Surplus excavated material result

- Page 85 and 86:

8. The width and depth of the trenc

- Page 87 and 88:

y 3 CONCRETE WORKS 3.1 Quality of C

- Page 89 and 90:

− A minimum of 2 No. of vibrators

- Page 91 and 92:

y These specifications give methods

- Page 93 and 94:

y 3.9.2.3 Gradation Seive No. 1 1/2

- Page 95 and 96:

C. Sulfate-resisting Portland cemen

- Page 97 and 98:

y Each cylinder or cube shall be ma

- Page 99 and 100:

y 3.9.20 General Requirements For P

- Page 101 and 102:

y 3.9.28 Inspection of Concrete The

- Page 103 and 104:

y reinforcement. The gap lefts from

- Page 105 and 106:

y compaction of concrete under the

- Page 107 and 108:

y 3.17 Culverts 3.17.1 Description

- Page 109 and 110:

y 4 MASONRY WORKS A. Quality of mix

- Page 111 and 112:

y 3.2.5 Table of Grading BS410 Siev

- Page 113 and 114:

5 PAVIOUR (INCLUDING MARBLE AND TER

- Page 115 and 116:

y This screed shall be 2 1/2 cm. th

- Page 117 and 118:

5.11 Concrete Block Surfacing y 5.1

- Page 119 and 120:

y When directed by the Engineer, te

- Page 121 and 122:

y These blocks shall be tested for

- Page 123 and 124:

y The paving blocks shall be laid o

- Page 125 and 126:

y 5.12 Tiles Testing All paving sha

- Page 127 and 128:

y 5.14.2 Test Standards Unless stat

- Page 129 and 130:

y If any of the 20 test block do no

- Page 131 and 132:

6 ROOFER AND CORROSION PROTECTION M

- Page 133 and 134:

y period of seven days as described

- Page 135 and 136:

y 6.2 PART I 6.3 Specifications 6.4

- Page 137 and 138:

y Rubberized bitumen/polythene shal

- Page 139 and 140:

y 6.15 Roof Finishes Type D: (Traff

- Page 141 and 142:

y 7.1.4 PVC Sheet Lining Materials

- Page 143 and 144:

y (a) An epoxy resin, acrylic, poly

- Page 145 and 146:

Notes : y (1) For manufactured item

- Page 147 and 148:

y Softwood in carpentry work shall

- Page 149 and 150:

y 9 IRONMONGERY 9.1 Generally The C

- Page 151 and 152:

y 10.4 Sundries Wrought steel balus

- Page 153 and 154:

y 11.2.3 Stainless Steel Stainless

- Page 155 and 156:

y (One) Unreinforced gel coats shal

- Page 157 and 158:

y (2) Electrical strength of sheet

- Page 159 and 160:

y Valves shall normally be metal se

- Page 161 and 162:

y 11.2.5.11 Reinforced Plastic Line

- Page 163 and 164:

y The complete seal plate shall be

- Page 165 and 166:

y Bright (high tensile) items to a

- Page 167 and 168:

y 11.2.6 Installation of Metal and

- Page 169 and 170:

y 'On-seating' installation : 5 lit

- Page 171 and 172:

y gutter outlet. Gutter brackets ar

- Page 173 and 174:

y comply with B.S. 1212 and be mark

- Page 175 and 176:

y Pipes shall be connected to manho

- Page 177 and 178:

y 12.18.3 Kitchen Sinks Is manufact

- Page 179 and 180:

y which the cast iron frame is embe

- Page 181 and 182:

y Two types of cast iron manholes c

- Page 183 and 184:

y - Not to be such proximity to any

- Page 185 and 186:

13 PLASTER WORK AND OTHER FLOOR WAL

- Page 187 and 188:

y refitted and jointed afterwards.

- Page 189 and 190:

y 13.10 Tiles All the tiling works

- Page 191 and 192:

y 14.4 Wired Glass Wired glass shal

- Page 193 and 194:

y 14.17 Measurement &Payment The ac

- Page 195 and 196:

y Synthetic alkyd based undercoatin

- Page 197 and 198:

y FINISHING PROGRESS 15.9 Internal

- Page 199 and 200:

The contractor has to supply and in

- Page 201 and 202:

y Paltough sheets are easily cut wi

- Page 203 and 204:

y 15.19.8 Cleaning and Finishing Fo

- Page 205 and 206:

y 16 ROADWAY LIGHTING 16.1 General

- Page 207 and 208:

y manufacturers installation instru

- Page 209 and 210:

y Eight) Armour Tests − − Sampl

- Page 211 and 212:

y Five) The Contractor shall leave

- Page 213 and 214:

shall be soundly made by use of har

- Page 215 and 216:

for hot dip galvanizing. Alternativ

- Page 217 and 218:

y − Contractor shall provide alon

- Page 219 and 220:

y − − − − Protective sheath

- Page 221 and 222:

components. It shall also be distin

- Page 223 and 224:

y − Utilization factor curve for

- Page 225 and 226:

y 17.5 Specification for Mid-Hinged

- Page 227 and 228:

y − The maximum and the minimum o

- Page 229 and 230:

y 17.7 Raising/Lowering Crown High

- Page 231 and 232:

y The lowering raising device with

- Page 233 and 234:

a 16A, 220V weatherproof socket and

- Page 235 and 236:

3. An approved locking device shall

- Page 237 and 238:

y 3rd) Gantry Sign Lighting Require

- Page 239 and 240:

- Fuse Holder shall be DIN rail mou

- Page 241 and 242:

y 17.13 Feeder Pillar Specification

- Page 243 and 244: y Height: 1000 mm (without canopy)

- Page 245 and 246: - Busbars shall be of the same ampe

- Page 247 and 248: y Auto ON/OFF; ON OFF 1. Power S

- Page 249 and 250: y TABLE No. 2 1000 W HPSV 400 W HPS

- Page 251 and 252: y 18.1.3.2 Application of Bituminou

- Page 253 and 254: y Unused bituminous material shall

- Page 255 and 256: y Traffic control and the applicati

- Page 257 and 258: y 18.4.2 Materials 18.4.2.1 Bitumin

- Page 259 and 260: y Transverse joints shall be made b

- Page 261 and 262: y 18.6.2 Bitumen Materials Unless o

- Page 263 and 264: y Table for DBM Aggregate Grading f

- Page 265 and 266: y The gradation of the combined agg

- Page 267 and 268: y Tanks for the storage of bitumen

- Page 269 and 270: y interval between the application

- Page 271 and 272: y they are to be mixed. When the mi

- Page 273 and 274: y The temperature of the D.B.M. jus

- Page 275 and 276: y The Contractor will make a survey

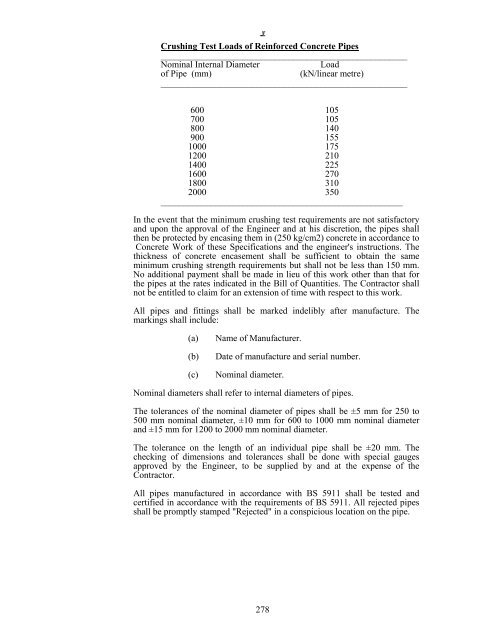

- Page 277 and 278: y 18.6.16.9 Trial Area After the ap

- Page 279 and 280: y 18.6.20 Payment No payment will b

- Page 281 and 282: y 18.7.2 Sampling of Bituminous Mat

- Page 283 and 284: 18.8.6 Binder y 18.8.6.1 Binder The

- Page 285 and 286: y In addition to the ballotini incl

- Page 287 and 288: y 18.9 Road Signs 18.9.1 Descriptio

- Page 289 and 290: y 18.9.6 Lettering Sign lettering s

- Page 291 and 292: y For structural purposes pipes sha

- Page 293: y unless otherwise specified and th

- Page 297 and 298: y 12) Wrinkles over than 3% of the

- Page 299 and 300: y 19.1.12.2 Trench Widths for Pipel

- Page 301 and 302: y 19.1.12.4 Pipelines Bedded on Tre

- Page 303 and 304: Group B and C Pipe Materials y Exce

- Page 305 and 306: y or a mixture of sand and clay, co

- Page 307 and 308: The encasing shall be by one of the

- Page 309 and 310: y 19.1.13 Pipe Work 19.1.13.1 Pipe

- Page 311 and 312: y Construction Solid Solid Solid Co

- Page 313 and 314: the public highway rights of way or

- Page 315 and 316: 20.4.1.1 Scope of Works y This sect

- Page 317 and 318: Removal of Existing Structures and

- Page 319 and 320: y Trench excavation work shall be p

- Page 321 and 322: y Any over-excavation at the bottom

- Page 323 and 324: y Trenches shall not be backfilled

- Page 325 and 326: y All pipes shall be laid and maint

- Page 327 and 328: y These fittings shall be either P.

- Page 329 and 330: 20.4.7 Indicator Posts to Pressure

- Page 331 and 332: y The pressure test shall be 1.5 ti

- Page 333 and 334: - Materials y - Precast Concrete El

- Page 335 and 336: 3) Welded Elbows y These shall cons

- Page 337 and 338: y Bend Test, Break Test and Tensile

- Page 339 and 340: y The traffic control plan shall ta

- Page 341 and 342: y 1. The Contractor shall be respon

- Page 343 and 344: always be at the same end. Painting

- Page 345 and 346:

y 20.4.18.1 General 2. Valves shall

- Page 347 and 348:

closed when the water rises in the

- Page 349 and 350:

17. Each hose connection shall have

- Page 351 and 352:

1. The Contractor shall furnish the

- Page 353 and 354:

Material IS0/BS Standard Descriptio

- Page 355 and 356:

y Material IS0/BS Standard Descript

- Page 357 and 358:

y replaced no backfilling will be a

- Page 359 and 360:

CCTV Inspection of Gravity Sewers y

- Page 361 and 362:

y 21.3 Inspection and Testing of Al

- Page 363 and 364:

y 21.3.3 Site Testing and Commissio

- Page 365 and 366:

y h) Work plan The contractor has t

- Page 367 and 368:

y quantities are executed without i

- Page 369:

The fittings required under this co