ABACA Activities in the Philippines - Unido

ABACA Activities in the Philippines - Unido

ABACA Activities in the Philippines - Unido

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Ref. No. CFC/FIGHF/09 CFC/UNIDO/FIDA 9<br />

4.0 Results and discussions<br />

4.1 Assessment of <strong>the</strong> efficiency of exist<strong>in</strong>g fiber extraction mach<strong>in</strong>es and tools<br />

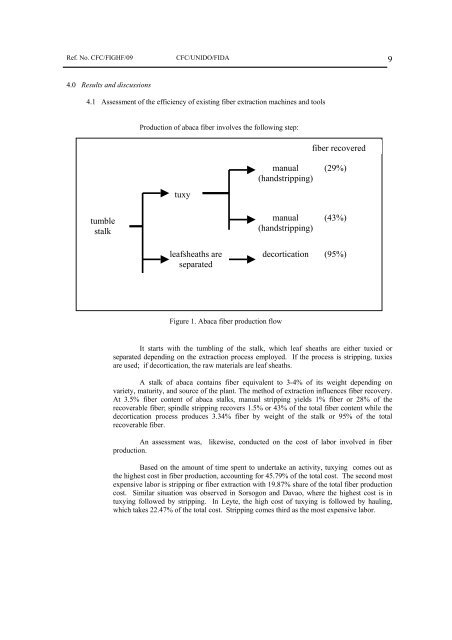

Production of abaca fiber <strong>in</strong>volves <strong>the</strong> follow<strong>in</strong>g step:<br />

fiber recovered<br />

manual<br />

(handstripp<strong>in</strong>g)<br />

(29%)<br />

tuxy<br />

tumble<br />

stalk<br />

manual<br />

(handstripp<strong>in</strong>g)<br />

(43%)<br />

leafsheaths are<br />

separated<br />

decortication<br />

(95%)<br />

Figure 1. Abaca fiber production flow<br />

It starts with <strong>the</strong> tumbl<strong>in</strong>g of <strong>the</strong> stalk, which leaf sheaths are ei<strong>the</strong>r tuxied or<br />

separated depend<strong>in</strong>g on <strong>the</strong> extraction process employed. If <strong>the</strong> process is stripp<strong>in</strong>g, tuxies<br />

are used; if decortication, <strong>the</strong> raw materials are leaf sheaths.<br />

A stalk of abaca conta<strong>in</strong>s fiber equivalent to 3-4% of its weight depend<strong>in</strong>g on<br />

variety, maturity, and source of <strong>the</strong> plant. The method of extraction <strong>in</strong>fluences fiber recovery.<br />

At 3.5% fiber content of abaca stalks, manual stripp<strong>in</strong>g yields 1% fiber or 28% of <strong>the</strong><br />

recoverable fiber; sp<strong>in</strong>dle stripp<strong>in</strong>g recovers 1.5% or 43% of <strong>the</strong> total fiber content while <strong>the</strong><br />

decortication process produces 3.34% fiber by weight of <strong>the</strong> stalk or 95% of <strong>the</strong> total<br />

recoverable fiber.<br />

An assessment was, likewise, conducted on <strong>the</strong> cost of labor <strong>in</strong>volved <strong>in</strong> fiber<br />

production.<br />

Based on <strong>the</strong> amount of time spent to undertake an activity, tuxy<strong>in</strong>g comes out as<br />

<strong>the</strong> highest cost <strong>in</strong> fiber production, account<strong>in</strong>g for 45.79% of <strong>the</strong> total cost. The second most<br />

expensive labor is stripp<strong>in</strong>g or fiber extraction with 19.87% share of <strong>the</strong> total fiber production<br />

cost. Similar situation was observed <strong>in</strong> Sorsogon and Davao, where <strong>the</strong> highest cost is <strong>in</strong><br />

tuxy<strong>in</strong>g followed by stripp<strong>in</strong>g. In Leyte, <strong>the</strong> high cost of tuxy<strong>in</strong>g is followed by haul<strong>in</strong>g,<br />

which takes 22.47% of <strong>the</strong> total cost. Stripp<strong>in</strong>g comes third as <strong>the</strong> most expensive labor.