ABACA Activities in the Philippines - Unido

ABACA Activities in the Philippines - Unido

ABACA Activities in the Philippines - Unido

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Ref. No. CFC/FIGHF/09 CFC/UNIDO/FIDA 20<br />

4.3 Development of abaca decorticat<strong>in</strong>g mach<strong>in</strong>e<br />

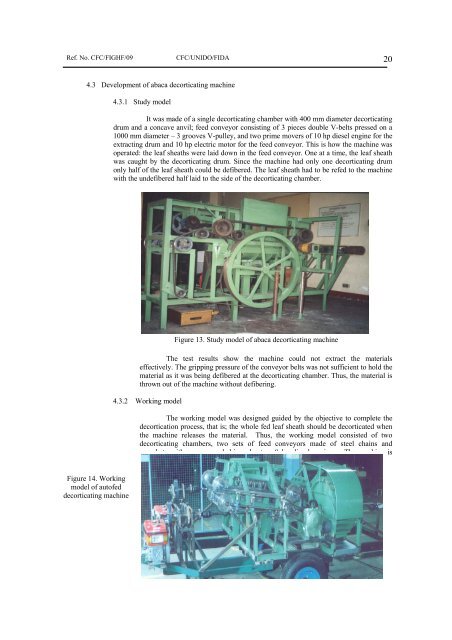

4.3.1 Study model<br />

It was made of a s<strong>in</strong>gle decorticat<strong>in</strong>g chamber with 400 mm diameter decorticat<strong>in</strong>g<br />

drum and a concave anvil; feed conveyor consist<strong>in</strong>g of 3 pieces double V-belts pressed on a<br />

1000 mm diameter – 3 grooves V-pulley, and two prime movers of 10 hp diesel eng<strong>in</strong>e for <strong>the</strong><br />

extract<strong>in</strong>g drum and 10 hp electric motor for <strong>the</strong> feed conveyor. This is how <strong>the</strong> mach<strong>in</strong>e was<br />

operated: <strong>the</strong> leaf sheaths were laid down <strong>in</strong> <strong>the</strong> feed conveyor. One at a time, <strong>the</strong> leaf sheath<br />

was caught by <strong>the</strong> decorticat<strong>in</strong>g drum. S<strong>in</strong>ce <strong>the</strong> mach<strong>in</strong>e had only one decorticat<strong>in</strong>g drum<br />

only half of <strong>the</strong> leaf sheath could be defibered. The leaf sheath had to be refed to <strong>the</strong> mach<strong>in</strong>e<br />

with <strong>the</strong> undefibered half laid to <strong>the</strong> side of <strong>the</strong> decorticat<strong>in</strong>g chamber.<br />

Figure 14. Work<strong>in</strong>g<br />

model of autofed<br />

decorticat<strong>in</strong>g mach<strong>in</strong>e<br />

The test results show <strong>the</strong> mach<strong>in</strong>e could not extract <strong>the</strong> materials<br />

effectively. The gripp<strong>in</strong>g pressure of <strong>the</strong> conveyor belts was not sufficient to hold <strong>the</strong><br />

material as it was be<strong>in</strong>g defibered at <strong>the</strong> decorticat<strong>in</strong>g chamber. Thus, <strong>the</strong> material is<br />

thrown out of <strong>the</strong> mach<strong>in</strong>e without defiber<strong>in</strong>g.<br />

4.3.2 Work<strong>in</strong>g model<br />

Figure 13. Study model of abaca decorticat<strong>in</strong>g mach<strong>in</strong>e<br />

The work<strong>in</strong>g model was designed guided by <strong>the</strong> objective to complete <strong>the</strong><br />

decortication process, that is; <strong>the</strong> whole fed leaf sheath should be decorticated when<br />

<strong>the</strong> mach<strong>in</strong>e releases <strong>the</strong> material. Thus, <strong>the</strong> work<strong>in</strong>g model consisted of two<br />

decorticat<strong>in</strong>g chambers, two sets of feed conveyors made of steel cha<strong>in</strong>s and<br />

sprockets with presser, and driven by two 8 hp diesel eng<strong>in</strong>es. The mach<strong>in</strong>e is<br />

mounted on chassis with pneumatic tires.