ABACA Activities in the Philippines - Unido

ABACA Activities in the Philippines - Unido

ABACA Activities in the Philippines - Unido

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Ref. No. CFC/FIGHF/09 CFC/UNIDO/FIDA 21<br />

The mach<strong>in</strong>e could extract good cleaned fiber with a recovery of 3.34%.<br />

However, <strong>the</strong>re was difficulty <strong>in</strong> transferr<strong>in</strong>g <strong>the</strong> materials from <strong>the</strong> first to <strong>the</strong><br />

second conveyor. To effect <strong>the</strong> proper transferr<strong>in</strong>g of material, it has to be guided<br />

manually. The steel cha<strong>in</strong>s caused <strong>the</strong> sta<strong>in</strong><strong>in</strong>g of <strong>the</strong> fiber (blacken<strong>in</strong>g of <strong>the</strong> portion<br />

gripped by <strong>the</strong> cha<strong>in</strong>), particularly <strong>in</strong> <strong>the</strong> second conveyor where <strong>the</strong> material be<strong>in</strong>g<br />

gripped was already defibered.<br />

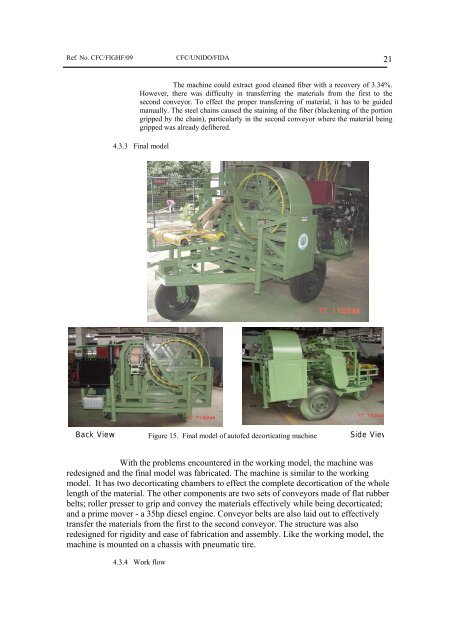

4.3.3 F<strong>in</strong>al model<br />

Back View<br />

Figure 15. F<strong>in</strong>al model of autofed decorticat<strong>in</strong>g mach<strong>in</strong>e<br />

Side View<br />

With <strong>the</strong> problems encountered <strong>in</strong> <strong>the</strong> work<strong>in</strong>g model, <strong>the</strong> mach<strong>in</strong>e was<br />

redesigned and <strong>the</strong> f<strong>in</strong>al model was fabricated. The mach<strong>in</strong>e is similar to <strong>the</strong> work<strong>in</strong>g<br />

model. It has two decorticat<strong>in</strong>g chambers to effect <strong>the</strong> complete decortication of <strong>the</strong> whole<br />

length of <strong>the</strong> material. The o<strong>the</strong>r components are two sets of conveyors made of flat rubber<br />

belts; roller presser to grip and convey <strong>the</strong> materials effectively while be<strong>in</strong>g decorticated;<br />

and a prime mover - a 35hp diesel eng<strong>in</strong>e. Conveyor belts are also laid out to effectively<br />

transfer <strong>the</strong> materials from <strong>the</strong> first to <strong>the</strong> second conveyor. The structure was also<br />

redesigned for rigidity and ease of fabrication and assembly. Like <strong>the</strong> work<strong>in</strong>g model, <strong>the</strong><br />

mach<strong>in</strong>e is mounted on a chassis with pneumatic tire.<br />

4.3.4 Work flow