ABACA Activities in the Philippines - Unido

ABACA Activities in the Philippines - Unido

ABACA Activities in the Philippines - Unido

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Ref. No. CFC/FIGHF/09 CFC/UNIDO/FIDA 22<br />

The extraction of abaca fiber us<strong>in</strong>g <strong>the</strong> autofed decorticat<strong>in</strong>g mach<strong>in</strong>e<br />

observed <strong>the</strong> follow<strong>in</strong>g work flow:<br />

3<br />

haul<strong>in</strong>g of<br />

stalks<br />

2<br />

dry<strong>in</strong>g of<br />

fiber<br />

4<br />

splitt<strong>in</strong>g of<br />

leafsheaths<br />

1<br />

delivery of<br />

fiber for<br />

dry<strong>in</strong>g<br />

2<br />

feed<strong>in</strong>g of<br />

materials<br />

1<br />

ga<strong>the</strong>r<strong>in</strong>g of<br />

fiber<br />

Figure 16. Work flow <strong>in</strong> <strong>the</strong> extraction of abaca fiber us<strong>in</strong>g autofed decorticat<strong>in</strong>g mach<strong>in</strong>e<br />

The figure above each work unit represents <strong>the</strong> number of laborers needed for each<br />

phase. As such, a total of 13 laborers will be employed to operate <strong>the</strong> autofed<br />

decorticat<strong>in</strong>g mach<strong>in</strong>e cont<strong>in</strong>uously for 8 hours.<br />

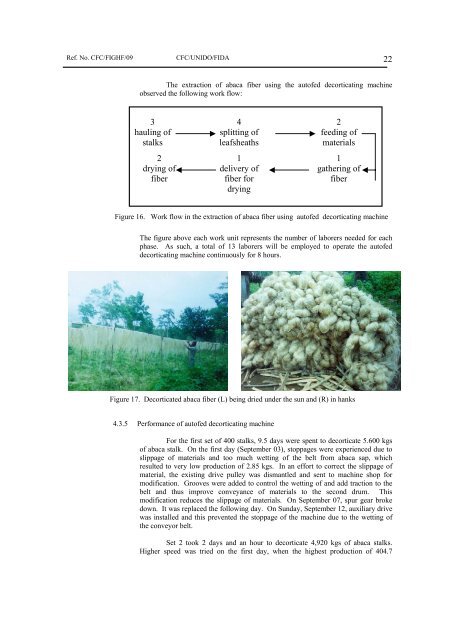

Figure 17. Decorticated abaca fiber (L) be<strong>in</strong>g dried under <strong>the</strong> sun and (R) <strong>in</strong> hanks<br />

4.3.5 Performance of autofed decorticat<strong>in</strong>g mach<strong>in</strong>e<br />

For <strong>the</strong> first set of 400 stalks, 9.5 days were spent to decorticate 5.600 kgs<br />

of abaca stalk. On <strong>the</strong> first day (September 03), stoppages were experienced due to<br />

slippage of materials and too much wett<strong>in</strong>g of <strong>the</strong> belt from abaca sap, which<br />

resulted to very low production of 2.85 kgs. In an effort to correct <strong>the</strong> slippage of<br />

material, <strong>the</strong> exist<strong>in</strong>g drive pulley was dismantled and sent to mach<strong>in</strong>e shop for<br />

modification. Grooves were added to control <strong>the</strong> wett<strong>in</strong>g of and add traction to <strong>the</strong><br />

belt and thus improve conveyance of materials to <strong>the</strong> second drum. This<br />

modification reduces <strong>the</strong> slippage of materials. On September 07, spur gear broke<br />

down. It was replaced <strong>the</strong> follow<strong>in</strong>g day. On Sunday, September 12, auxiliary drive<br />

was <strong>in</strong>stalled and this prevented <strong>the</strong> stoppage of <strong>the</strong> mach<strong>in</strong>e due to <strong>the</strong> wett<strong>in</strong>g of<br />

<strong>the</strong> conveyor belt.<br />

Set 2 took 2 days and an hour to decorticate 4,920 kgs of abaca stalks.<br />

Higher speed was tried on <strong>the</strong> first day, when <strong>the</strong> highest production of 404.7