Reliable Plant July August 2008

Reliable Plant July August 2008

Reliable Plant July August 2008

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

will create a competitive advantage. However, if the manufacturing<br />

system isn’t set up to create that solution, we’re left with the<br />

following options:<br />

A) Withdraw the offering from the portfolio, which may be<br />

difficult if the marketing team has already committed to deliver<br />

the offering to a customer or to the market in general.<br />

B) Manufacture the product or packaging solution using the<br />

existing processes and machines, which often leads to compromised<br />

availability, speed and/or quality – the three elements of<br />

overall business effectiveness/overall equipment effectiveness<br />

(OBE/OEE).<br />

C) Purchase a bespoke machine or manufacturing system to<br />

deliver the product/packaging solution, increasing the net operating<br />

asset in place (NOAP), driving down asset utilization and<br />

potentially reducing return on net assets (RONA).<br />

Functionally, where did things go wrong? In my view, the two<br />

following underlying organizational root causes lead to this very<br />

common scenario where sales and marketing oversells the manufacturing<br />

capabilities of the plant:<br />

1) Focused on driving top-line revenue and/or market share,<br />

the sales and marketing team develops and/or offers a<br />

product/packaging solution that lacks manufacturability. Their<br />

vector: increase sales and market share, period.<br />

2) Focused on minimizing cost, the manufacturing process and<br />

equipment design team lack the vision to build manufacturing flexibility<br />

into the process. Their vector: get currently required<br />

manufacturing capability installed fast and with the lowest upfront<br />

purchase price.<br />

Clearly, communication is our dilemma. However, I believe<br />

communication suffers because functional groups are often<br />

focused on the wrong objective within their silo. Irrespective of<br />

how they are written, all mission statements require the organization<br />

to create value. Very few functional groups pursue value<br />

creation within their silo. Some are focused on driving top-line<br />

revenue, while others are focused on cost containment. The<br />

problem is that you can increase revenue and decrease contribution<br />

margin. Most organizations have product SKUs and/or<br />

customers that are profit-losers because of excessive manufacturing<br />

costs, excessive customer support costs, etc. Also, it’s very<br />

easy to reduce operating costs and simultaneously destroy profitability.<br />

Many procurement teams, for instance, focus their efforts<br />

on reducing the cost of raw materials, which is great, unless the<br />

cost savings reduce manufacturing effectiveness – affecting availability,<br />

yield and/or quality.<br />

What is the moral to the story? Get your organizational vectors<br />

aligned. The key to success is to create business processes and a<br />

culture (a.k.a. behaviors) that drive and encourage cross-functional<br />

communication and to carefully focus the actions of each<br />

function on the overall organizational mission, which must be<br />

expressed in the form of value creation and contribution margin<br />

for the profit-seeking entity. This changes the direction of the organizational<br />

vectors back toward the mission (Figure 2).<br />

This sounds easy, but it’s not. Functional groups tend to focus<br />

on revenue maximization or cost minimization because they are<br />

both much easier to measure than value. Measuring value requires<br />

that we consider the impact other functional groups have on the<br />

equation, which requires communication. Do you see my point?<br />

The value-seeking organization works hard to blur the barriers<br />

between the functional groups instead of blurring the functions<br />

themselves. This requires communication and enables value<br />

creation, which serves the mission!<br />

Accounting<br />

and Finance<br />

Product<br />

Engineering<br />

Accounting<br />

and Finance<br />

Product<br />

Engineering<br />

Talent<br />

Management<br />

Process<br />

Engineering<br />

Talent<br />

Management<br />

Process<br />

Engineering<br />

Mission<br />

Mission<br />

Manufacturing<br />

Maintenance<br />

Sales and<br />

Marketing<br />

Manufacturing<br />

Maintenance<br />

Sales and<br />

Marketing<br />

Manufacturing<br />

Operations<br />

Supply<br />

Chain<br />

Manufacturing<br />

Operations<br />

Supply<br />

Chain<br />

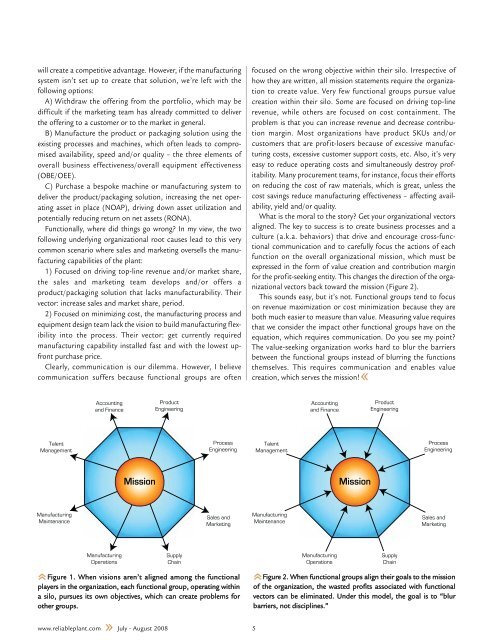

Figure 1. When visions aren’t aligned among the functional<br />

players in the organization, each functional group, operating within<br />

a silo, pursues its own objectives, which can create problems for<br />

other groups.<br />

Figure 2. When functional groups align their goals to the mission<br />

of the organization, the wasted profits associated with functional<br />

vectors can be eliminated. Under this model, the goal is to “blur<br />

barriers, not disciplines.”<br />

www.reliableplant.com <strong>July</strong> - <strong>August</strong> <strong>2008</strong> 5