Reliable Plant July August 2008

Reliable Plant July August 2008

Reliable Plant July August 2008

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

BY PAUL V. ARNOLD<br />

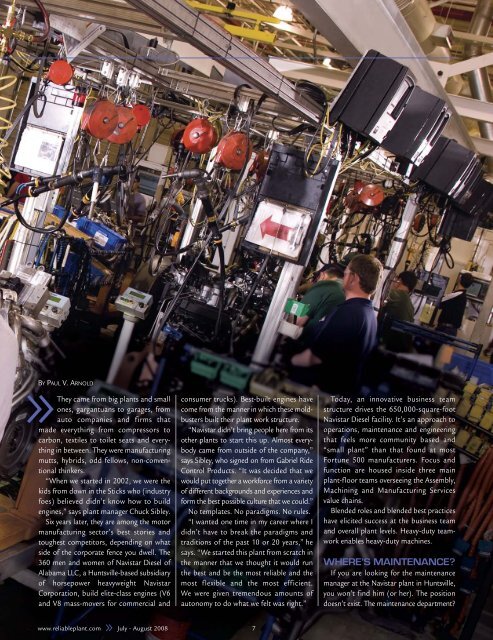

They came from big plants and small<br />

ones, gargantuans to garages, from<br />

auto companies and firms that<br />

made everything from compressors to<br />

carbon, textiles to toilet seats and everything<br />

in between. They were manufacturing<br />

mutts, hybrids, odd fellows, non-conventional<br />

thinkers.<br />

“When we started in 2002, we were the<br />

kids from down in the Sticks who (industry<br />

foes) believed didn’t know how to build<br />

engines,” says plant manager Chuck Sibley.<br />

Six years later, they are among the motor<br />

manufacturing sector’s best stories and<br />

toughest competitors, depending on what<br />

side of the corporate fence you dwell. The<br />

360 men and women of Navistar Diesel of<br />

Alabama LLC, a Huntsville-based subsidiary<br />

of horsepower heavyweight Navistar<br />

Corporation, build elite-class engines (V6<br />

and V8 mass-movers for commercial and<br />

consumer trucks). Best-built engines have<br />

come from the manner in which these moldbusters<br />

built their plant work structure.<br />

“Navistar didn’t bring people here from its<br />

other plants to start this up. Almost everybody<br />

came from outside of the company,”<br />

says Sibley, who signed on from Gabriel Ride<br />

Control Products. “It was decided that we<br />

would put together a workforce from a variety<br />

of different backgrounds and experiences and<br />

form the best possible culture that we could.”<br />

No templates. No paradigms. No rules.<br />

“I wanted one time in my career where I<br />

didn’t have to break the paradigms and<br />

traditions of the past 10 or 20 years,” he<br />

says. “We started this plant from scratch in<br />

the manner that we thought it would run<br />

the best and be the most reliable and the<br />

most flexible and the most efficient.<br />

We were given tremendous amounts of<br />

autonomy to do what we felt was right.”<br />

Today, an innovative business team<br />

structure drives the 650,000-square-foot<br />

Navistar Diesel facility. It’s an approach to<br />

operations, maintenance and engineering<br />

that feels more community based and<br />

“small plant” than that found at most<br />

Fortune 500 manufacturers. Focus and<br />

function are housed inside three main<br />

plant-floor teams overseeing the Assembly,<br />

Machining and Manufacturing Services<br />

value chains.<br />

Blended roles and blended best practices<br />

have elicited success at the business team<br />

and overall plant levels. Heavy-duty teamwork<br />

enables heavy-duty machines.<br />

WHERE’S MAINTENANCE?<br />

If you are looking for the maintenance<br />

manager at the Navistar plant in Huntsville,<br />

you won’t find him (or her). The position<br />

doesn’t exist. The maintenance department?<br />

www.reliableplant.com <strong>July</strong> - <strong>August</strong> <strong>2008</strong> 7