Fortron PPS Product Brochure (B240) - Hi Polymers

Fortron PPS Product Brochure (B240) - Hi Polymers

Fortron PPS Product Brochure (B240) - Hi Polymers

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Fortron</strong> ®<br />

Polyphenylene sulphide (<strong>PPS</strong>)<br />

Change<br />

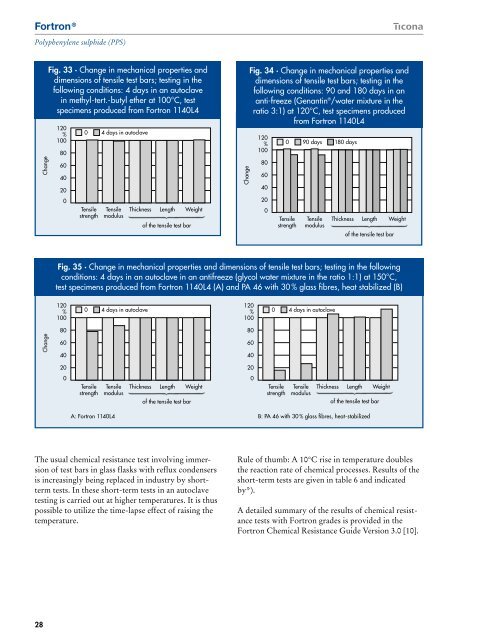

Fig. 33 · Change in mechanical properties and<br />

dimensions of tensile test bars; testing in the<br />

following conditions: 4 days in an autoclave<br />

in methyl-tert.-butyl ether at 100°C, test<br />

specimens produced from <strong>Fortron</strong> 1140L4<br />

120<br />

%<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

0 4 days in autoclave<br />

Tensile<br />

strength<br />

Tensile<br />

modulus<br />

Thickness Length Weight<br />

of the tensile test bar<br />

Change<br />

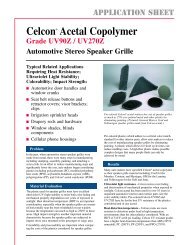

Fig. 34 · Change in mechanical properties and<br />

dimensions of tensile test bars; testing in the<br />

following conditions: 90 and 180 days in an<br />

anti-freeze (Genantin ® /water mixture in the<br />

ratio 3:1) at 120°C, test specimens produced<br />

from <strong>Fortron</strong> 1140L4<br />

120<br />

%<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

0 90 days 180 days<br />

Tensile<br />

strength<br />

Tensile<br />

modulus<br />

Thickness Length Weight<br />

of the tensile test bar<br />

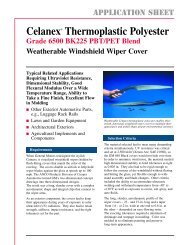

Fig. 35 · Change in mechanical properties and dimensions of tensile test bars; testing in the following<br />

conditions: 4 days in an autoclave in an antifreeze (glycol water mixture in the ratio 1:1) at 150°C,<br />

test specimens produced from <strong>Fortron</strong> 1140L4 (A) and PA 46 with 30 % glass fibres, heat stabilized (B)<br />

120<br />

%<br />

100<br />

0 4 days in autoclave<br />

120<br />

%<br />

100<br />

0 4 days in autoclave<br />

Change<br />

80<br />

60<br />

40<br />

80<br />

60<br />

40<br />

20<br />

20<br />

0<br />

Tensile<br />

strength<br />

Tensile<br />

modulus<br />

Thickness Length Weight<br />

of the tensile test bar<br />

0<br />

Tensile<br />

strength<br />

Tensile<br />

modulus<br />

Thickness Length Weight<br />

of the tensile test bar<br />

A: <strong>Fortron</strong> 1140L4 B: PA 46 with 30 % glass fibres, heat-stabilized<br />

The usual chemical resistance test involving immersion<br />

of test bars in glass flasks with reflux condensers<br />

is increasingly being replaced in industry by shortterm<br />

tests. In these short-term tests in an autoclave<br />

testing is carried out at higher temperatures. It is thus<br />

possible to utilize the time-lapse effect of raising the<br />

temperature.<br />

Rule of thumb: A 10°C rise in temperature doubles<br />

the reaction rate of chemical processes. Results of the<br />

short-term tests are given in table 6 and indicated<br />

by*).<br />

A detailed summary of the results of chemical resistance<br />

tests with <strong>Fortron</strong> grades is provided in the<br />

<strong>Fortron</strong> Chemical Resistance Guide Version 3.0 [10].<br />

28