- Page 1 and 2:

Please note that this PDF is subjec

- Page 3 and 4:

WORLD ENERGY 2 0 11 OUTLOOK

- Page 5 and 6:

FOREWORD It is the job of governmen

- Page 7 and 8:

ACKNOWLEDGEMENTS © OECD/IEA, 2011

- Page 9 and 10:

© OECD/IEA, 2011 Alexey Biteryakov

- Page 11 and 12:

© OECD/IEA, 2011 James Jensen Jan-

- Page 13 and 14:

© OECD/IEA, 2011 Jeff Piper Oleg P

- Page 15 and 16:

Liu Xiaoli Vitaly Yermakov Shigehir

- Page 17 and 18:

CONTEXT AND ANALYTICAL FRAMEWORK 1

- Page 19 and 20:

Trade 136 Trends in oil and gas pro

- Page 21 and 22:

9 Implications of Russia’s energy

- Page 23 and 24:

Electricity access - financing on-g

- Page 25 and 26:

3.5 Average annual change in transp

- Page 27 and 28:

5.19 Renewables grid integration co

- Page 29 and 30:

8.13 Changes in Russian natural gas

- Page 31 and 32:

11.14 Cumulative coal-supply invest

- Page 33 and 34:

List of tables Part A: GLOBAL ENERG

- Page 35 and 36:

10.5 CO 2 emissions from coal combu

- Page 37 and 38:

8.5 The “Northern Route” to mar

- Page 39 and 40:

Comments and questions are welcome

- Page 41 and 42:

EXECUTIVE SUMMARY “If we don’t

- Page 43 and 44:

Rising transport demand and upstrea

- Page 45 and 46:

Treading water or full steam ahead

- Page 47 and 48:

Achieving energy for all will not c

- Page 49 and 50:

PART A GLOBAL ENERGY TRENDS PREFACE

- Page 51 and 52:

CHAPTER 1 CONTEXT AND ANALYTICAL FR

- Page 53 and 54:

East and North Africa, a region tha

- Page 55 and 56:

© OECD/IEA, 2011 Chapter 1 - Conte

- Page 57 and 58:

The New Policies Scenario should no

- Page 59 and 60:

on welfare programmes. While this i

- Page 61 and 62:

6.8 billion in 2009 to around 8.6 b

- Page 63 and 64:

Energy prices The evolution of ener

- Page 65 and 66:

Natural gas prices Historically, na

- Page 67 and 68:

Figure 1.2 Ratio of average natura

- Page 69 and 70:

© OECD/IEA, 2011 In the 450 Scenar

- Page 71 and 72:

CHAPTER 2 ENERGY PROJECTIONS TO 203

- Page 73 and 74:

In the 450 Scenario, global energy

- Page 75 and 76:

Figure 2.4 World energy-related CO

- Page 77 and 78:

Box 2.1 The impact of lower near-t

- Page 79 and 80:

SPOTLIGHT © OECD/IEA, 2011 What ar

- Page 81 and 82:

Figure 2.7 Shares of energy source

- Page 83 and 84:

of the total in 2035, the absolute

- Page 85 and 86:

© OECD/IEA, 2011 In Latin America,

- Page 87 and 88:

adoption of hybrids (32% of passeng

- Page 89 and 90:

Figure 2.12 Incremental energy dem

- Page 91 and 92:

Figure 2.14 Incremental world ener

- Page 93 and 94:

production continue to clarify the

- Page 95 and 96:

stabilising thereafter, to settle a

- Page 97 and 98:

The answer will depend on China’s

- Page 99 and 100:

investment needs are not as high, b

- Page 101 and 102:

Energy-related emissions Greenhouse

- Page 103 and 104:

© OECD/IEA, 2011 Chapter 2 - Energ

- Page 105 and 106:

CHAPTER 3 OIL MARKET OUTLOOK Will i

- Page 107 and 108:

the assumed higher GDP growth, howe

- Page 109 and 110:

Policies Scenario, OECD primary dem

- Page 111 and 112:

Chapter 13 for a discussion of ener

- Page 113 and 114:

if large-scale projects were succes

- Page 115 and 116:

Passenger light-duty vehicles Passe

- Page 117 and 118:

countries own a car today, while av

- Page 119 and 120:

Box 3.1 The future of car making T

- Page 121 and 122:

wait-and-see strategy in a still na

- Page 123 and 124:

eserves additions amounted to 29 bi

- Page 125 and 126:

Figure 3.15 World oil production i

- Page 127 and 128:

© OECD/IEA, 2011 By country, Iraq

- Page 129 and 130:

in production from older fields. Ru

- Page 131 and 132:

States (US DOE/EIA, 2011a). Of cour

- Page 133 and 134:

Europe’s production decline is we

- Page 135 and 136:

have acknowledged that the target l

- Page 137 and 138:

© OECD/IEA, 2011 this potential wi

- Page 139 and 140:

© OECD/IEA, 2011 Chapter 3 - Oil m

- Page 141 and 142:

and most of the easily accessible o

- Page 143 and 144:

egions where international oil comp

- Page 145 and 146:

Trends in upstream spending differ

- Page 147 and 148:

Impact of deferred upstream investm

- Page 149 and 150:

good by other regions. Higher oil a

- Page 151 and 152:

atios of gas and coal prices to oil

- Page 153 and 154:

Oil demand falls much less in volum

- Page 155 and 156:

than offset by higher oil prices (a

- Page 157 and 158:

CHAPTER 4 NATURAL GAS MARKET OUTLOO

- Page 159 and 160:

decreases through the projection pe

- Page 161 and 162:

Middle East (included in “other e

- Page 163 and 164:

Figure 4.4 Primary natural gas dem

- Page 165 and 166:

Table 4.3 Primary natural gas prod

- Page 167 and 168:

Table 4.4 Primary natural gas prod

- Page 169 and 170:

production growth in Iran is likely

- Page 171 and 172:

projections of the New Policies Sce

- Page 173 and 174:

of additional unconventional gas su

- Page 175 and 176:

SPOTLIGHT Do all roads lead to a Go

- Page 177 and 178:

CHAPTER 5 POWER AND RENEWABLES OUTL

- Page 179 and 180:

Around 80% of the growth in electri

- Page 181 and 182:

Figure 5.2 Share of world electric

- Page 183 and 184:

Figure 5.4 Incremental global coal

- Page 185 and 186:

driving the growth in this technolo

- Page 187 and 188:

wind power producer. Generation fro

- Page 189 and 190:

In OECD countries, the reduction in

- Page 191 and 192:

© OECD/IEA, 2011 Chapter 5 - Power

- Page 193 and 194:

Box 5.1 Costs of integrating varia

- Page 195 and 196:

of renewables can also improve capa

- Page 197 and 198:

Focus on T&D infrastructure Robust

- Page 199 and 200:

years and this is set to continue.

- Page 201 and 202:

© OECD/IEA, 2011 Chapter 5 - Power

- Page 203 and 204:

total system integration costs (see

- Page 205 and 206:

systems, smart grids can also incre

- Page 207 and 208:

CHAPTER 6 CLIMATE CHANGE AND THE 45

- Page 209 and 210:

Box 6.1 What is special about 2°C

- Page 211 and 212:

© OECD/IEA, 2011 was driven by eco

- Page 213 and 214:

Table 6.1 World anthropogenic gree

- Page 215 and 216:

over 6 000 terawatt hours (TWh) in

- Page 217 and 218:

Efficiency policies are by far the

- Page 219 and 220:

Union in the 450 Scenario). China a

- Page 221 and 222:

SPOTLIGHT The International Year of

- Page 223 and 224:

The power generation sector plays a

- Page 225 and 226:

© OECD/IEA, 2011 Chapter 6 - Clima

- Page 227 and 228:

the total). 7 Refurbishment of buil

- Page 229 and 230:

which by 2035 are $42/tonne, or 38%

- Page 231 and 232:

Implications of delayed action This

- Page 233 and 234:

cumulative budgeted emissions of th

- Page 235 and 236:

of its technical lifetime before 20

- Page 237 and 238:

the case for transport, however, th

- Page 239 and 240:

Figure 6.17 Potential CO 2 emissio

- Page 241 and 242:

example, it would require an averag

- Page 243 and 244:

Figure 6.19 Change in global energ

- Page 245 and 246:

PART B OUTLOOK FOR RUSSIAN ENERGY P

- Page 247 and 248:

CHAPTER 7 RUSSIAN DOMESTIC ENERGY P

- Page 249 and 250:

(Urengoy and Yamburg) that have mad

- Page 251 and 252:

Figure 7.2 Energy production in Ru

- Page 253 and 254:

Trends in policies and governance T

- Page 255 and 256:

and those in Russian strategy docum

- Page 257 and 258:

Another target adopted by the Russi

- Page 259 and 260:

Figure 7.4 Total energy costs as a

- Page 261 and 262:

accounts for a significant share (F

- Page 263 and 264:

stricter building codes, are consid

- Page 265 and 266:

Figure 7.9 Primary energy savings

- Page 267 and 268:

this decline is projected to contin

- Page 269 and 270:

The current contribution of non-fos

- Page 271 and 272:

energy economy and the government c

- Page 273 and 274:

Figure 7.15 Age profile of install

- Page 275 and 276:

Reform efforts directed at the elec

- Page 277 and 278:

difficult to assess with any accura

- Page 279 and 280:

energy demand in the transport sect

- Page 281 and 282:

at around 20 kilogrammes of oil equ

- Page 283 and 284:

In the New Policies Scenario, polic

- Page 285 and 286:

CHAPTER 8 RUSSIAN RESOURCES AND SUP

- Page 287 and 288:

Figure 8.2 Russian oil balance in

- Page 289 and 290:

Russian industrial groups (and ther

- Page 291 and 292:

subsequent updates, 6 IEA analysis

- Page 293 and 294:

Our USGS-based estimates have been

- Page 295 and 296:

9.6 mb/d throughout the period to 2

- Page 297 and 298:

incentives for companies to invest

- Page 299 and 300:

© OECD/IEA, 2011 Chapter 8 - Russi

- Page 301 and 302:

Production in Eastern Siberia is pr

- Page 303 and 304:

Estimating decline rates at existin

- Page 305 and 306:

Natural gas Resources Proven reserv

- Page 307 and 308:

ecoverable resources suggest, Russi

- Page 309 and 310:

SPOTLIGHT © OECD/IEA, 2011 The las

- Page 311 and 312:

Figure 8.13 Changes in Russian nat

- Page 313 and 314:

Flaring The rate of utilisation of

- Page 315 and 316:

© OECD/IEA, 2011 Chapter 8 - Russi

- Page 317 and 318:

Box 8.5 The “Northern Route” t

- Page 319 and 320:

information about project developme

- Page 321 and 322:

the Kansko-Achinsk basin and Easter

- Page 323 and 324:

not been affected by any change of

- Page 325 and 326:

Russia has significant uranium reso

- Page 327 and 328:

obstacle, as discussed for the coal

- Page 329 and 330:

The adoption of renewable technolog

- Page 331 and 332:

CHAPTER 9 IMPLICATIONS OF RUSSIA’

- Page 333 and 334:

Figure 9.1 Structure of Russian ex

- Page 335 and 336:

Taken together, our assumption for

- Page 337 and 338:

in infrastructure for liquefied nat

- Page 339 and 340:

in the Middle East (see Chapter 3).

- Page 341 and 342:

There is similar evidence in the oi

- Page 343 and 344:

with the overall aim to decrease th

- Page 345 and 346:

Table 9.1 Main gas trade flows fro

- Page 347 and 348:

At the same time, the position of R

- Page 349 and 350:

Policies Scenario, so that they are

- Page 351 and 352:

Comparing this Outlook with Russian

- Page 353 and 354:

PART C OUTLOOK FOR COAL MARKETS PRE

- Page 355 and 356:

CHAPTER 10 COAL DEMAND PROSPECTS Tr

- Page 357 and 358:

Box 10.1 A decade of booming coal

- Page 359 and 360: the imposition of a carbon price an

- Page 361 and 362: Table 10.3 Summary of the main dri

- Page 363 and 364: Figure 10.5 World crude steel prod

- Page 365 and 366: under $200/tonne in nominal terms b

- Page 367 and 368: Box 10.3 Coal-fired power generati

- Page 369 and 370: The projections described above, an

- Page 371 and 372: Table 10.4 Levelised electricity g

- Page 373 and 374: Fuel choice in industry Coal has di

- Page 375 and 376: ange of capital costs only for capa

- Page 377 and 378: In the 450 Scenario, OECD coal dema

- Page 379 and 380: © OECD/IEA, 2011 PCC plants, they

- Page 381 and 382: Figure 10.16 Coal-fired generating

- Page 383 and 384: coal demand rebounds in the short t

- Page 385 and 386: energy intensity and carbon intensi

- Page 387 and 388: Figure 10.20 New additions of powe

- Page 389 and 390: © OECD/IEA, 2011 around 85% of the

- Page 391 and 392: Figure 10.24 Coal-fired generating

- Page 393 and 394: In the New Policies Scenario, coal

- Page 395 and 396: over the projection period, as the

- Page 397 and 398: urning for power generation. Load f

- Page 399 and 400: CHAPTER 11 COAL SUPPLY AND INVESTME

- Page 401 and 402: Table 11.1 Coal* production by typ

- Page 403 and 404: in 2009 (Figure 11.2). Marginal cha

- Page 405 and 406: Just under three-quarters, or nearl

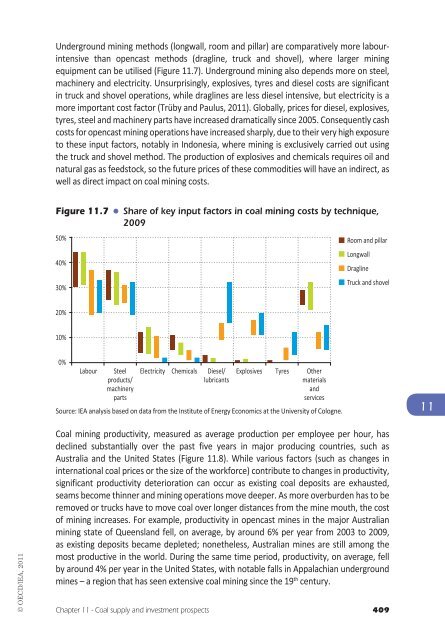

- Page 407 and 408: generally risen much less than inte

- Page 409: and the United States have moved up

- Page 413 and 414: near the coast. Furthermore, bottle

- Page 415 and 416: capacity in the next two to four ye

- Page 417 and 418: exemptions and credits, grants for

- Page 419 and 420: coal derivatives, which together al

- Page 421 and 422: Table 11.6 Key figures for the 30

- Page 423 and 424: Trade prospects In the New Policies

- Page 425 and 426: Colombia, along with new entrants s

- Page 427 and 428: freight, to connect the coal-fields

- Page 429 and 430: monopoly, which is able to extract

- Page 431 and 432: the west of China, together with in

- Page 433 and 434: the past few years, especially of c

- Page 435 and 436: Indonesian and South African steam

- Page 437 and 438: coal sold at the mine-mouth. The co

- Page 439 and 440: © OECD/IEA, 2011 rates, total coal

- Page 441 and 442: their markets. Additionally, over t

- Page 443 and 444: Figure 11.25 Coal production in So

- Page 445 and 446: © OECD/IEA, 2011 Figure 11.26 Har

- Page 447 and 448: PART D SPECIAL TOPICS PREFACE Part

- Page 449 and 450: CHAPTER 12 THE IMPLICATIONS OF LESS

- Page 451 and 452: On the basis of a necessarily arbit

- Page 453 and 454: of the construction starts in 2010,

- Page 455 and 456: © OECD/IEA, 2011 SPOTLIGHT How did

- Page 457 and 458: © OECD/IEA, 2011 the country’s 5

- Page 459 and 460: Our projections of future nuclear p

- Page 461 and 462:

projected in the New Policies Scena

- Page 463 and 464:

Figure 12.4 Power generation by fu

- Page 465 and 466:

period 2011 to 2035 are higher by 1

- Page 467 and 468:

In short, to the extent that energy

- Page 469 and 470:

other generating options because of

- Page 471 and 472:

CHAPTER 13 ENERGY FOR ALL Financing

- Page 473 and 474:

© OECD/IEA, 2011 International con

- Page 475 and 476:

Table 13.1 People without access t

- Page 477 and 478:

Box 13.2 Measuring investment in m

- Page 479 and 480:

In the New Policies Scenario, aroun

- Page 481 and 482:

© OECD/IEA, 2011 Chapter 13 - Ener

- Page 483 and 484:

significant progress in establishin

- Page 485 and 486:

most suitable option for all urban

- Page 487 and 488:

In the Energy for All Case, hydropo

- Page 489 and 490:

additional investment of $20 billio

- Page 491 and 492:

As well as the economic development

- Page 493 and 494:

to pay. In these areas, the share o

- Page 495 and 496:

Electricity access - financing mini

- Page 497 and 498:

y entrepreneurs providing solar por

- Page 499 and 500:

The government, through a national

- Page 501 and 502:

Multilateral and bilateral developm

- Page 503 and 504:

generation at an investment cost of

- Page 505 and 506:

including to end-users, to generate

- Page 507 and 508:

to be sufficiently expert regarding

- Page 509 and 510:

CHAPTER 14 DEVELOPMENTS IN ENERGY S

- Page 511 and 512:

G-20 and APEC leaders in 2009 and 2

- Page 513 and 514:

availability and foreign currency e

- Page 515 and 516:

subsidies, which may subsidise part

- Page 517 and 518:

Figure 14.3 Economic cost of fossi

- Page 519 and 520:

© OECD/IEA, 2011 Chapter 14 - Deve

- Page 521 and 522:

In practice, the poor capture only

- Page 523 and 524:

that would follow from subsidy remo

- Page 525 and 526:

SPOTLIGHT Are the G-20 and APEC com

- Page 527 and 528:

lessens the burden of the rising co

- Page 529 and 530:

© OECD/IEA, 2011 While the return

- Page 531 and 532:

Measuring renewable-energy subsidie

- Page 533 and 534:

grow considerably in non-OECD count

- Page 535 and 536:

exploited earlier, but there are ex

- Page 537 and 538:

© OECD/IEA, 2011 in the United Sta

- Page 539 and 540:

As depicted in the 450 Scenario, mo

- Page 541 and 542:

lowest in Japan, due partly to elec

- Page 543 and 544:

© OECD/IEA, 2011 ANNEXES

- Page 545 and 546:

ANNEX A TABLES FOR SCENARIO PROJECT

- Page 547 and 548:

© OECD/IEA, 2011 World: Current Po

- Page 549 and 550:

World: Current Policies and 450 Sce

- Page 551 and 552:

© OECD/IEA, 2011 OECD: Current Pol

- Page 553 and 554:

OECD: Current Policies and 450 Scen

- Page 555 and 556:

© OECD/IEA, 2011 OECD Americas: Cu

- Page 557 and 558:

OECD Americas: Current Policies and

- Page 559 and 560:

© OECD/IEA, 2011 United States: Cu

- Page 561 and 562:

United States: Current Policies and

- Page 563 and 564:

© OECD/IEA, 2011 OECD Europe: Curr

- Page 565 and 566:

OECD Europe: Current Policies and 4

- Page 567 and 568:

© OECD/IEA, 2011 European Union: C

- Page 569 and 570:

European Union: Current Policies an

- Page 571 and 572:

© OECD/IEA, 2011 OECD Asia Oceania

- Page 573 and 574:

OECD Asia Oceania: Current Policies

- Page 575 and 576:

© OECD/IEA, 2011 Japan: Current Po

- Page 577 and 578:

Japan: Current Policies and 450 Sce

- Page 579 and 580:

© OECD/IEA, 2011 Non-OECD: Current

- Page 581 and 582:

Non-OECD: Current Policies and 450

- Page 583 and 584:

© OECD/IEA, 2011 E. Europe/Eurasia

- Page 585 and 586:

E. Europe/Eurasia: Current Policies

- Page 587 and 588:

© OECD/IEA, 2011 Russia: Current P

- Page 589 and 590:

Russia: Current Policies and 450 Sc

- Page 591 and 592:

© OECD/IEA, 2011 Non-OECD Asia: Cu

- Page 593 and 594:

Non-OECD Asia: Current Policies and

- Page 595 and 596:

© OECD/IEA, 2011 China: Current Po

- Page 597 and 598:

China: Current Policies and 450 Sce

- Page 599 and 600:

© OECD/IEA, 2011 India: Current Po

- Page 601 and 602:

India: Current Policies and 450 Sce

- Page 603 and 604:

© OECD/IEA, 2011 Middle East: Curr

- Page 605 and 606:

Middle East: Current Policies and 4

- Page 607 and 608:

© OECD/IEA, 2011 Africa: Current P

- Page 609 and 610:

Africa: Current Policies and 450 Sc

- Page 611 and 612:

© OECD/IEA, 2011 Latin America: Cu

- Page 613 and 614:

Latin America: Current Policies and

- Page 615 and 616:

© OECD/IEA, 2011 Brazil: Current P

- Page 617 and 618:

Brazil: Current Policies and 450 Sc

- Page 619 and 620:

ANNEX B POLICIES AND MEASURES BY SC

- Page 621 and 622:

The specific policies adopted for d

- Page 623 and 624:

© OECD/IEA, 2011 Annex B - Policie

- Page 625 and 626:

© OECD/IEA, 2011 Annex B - Policie

- Page 627 and 628:

© OECD/IEA, 2011 Annex B - Policie

- Page 629 and 630:

© OECD/IEA, 2011 Annex B - Policie

- Page 631 and 632:

ANNEX C UNITS, DEFINITIONS, REGIONA

- Page 633 and 634:

© OECD/IEA, 2011 Definitions Advan

- Page 635 and 636:

Coking coal Coking coal is a type o

- Page 637 and 638:

departure and port of arrival, and

- Page 639 and 640:

manufacturing and mining), transpor

- Page 641 and 642:

Latin America Argentina, Bolivia, B

- Page 643 and 644:

© OECD/IEA, 2011 CNG compressed na

- Page 645 and 646:

PSA PV RD&D RDD&D SAGD SCO SO 2 SRM

- Page 647 and 648:

ANNEX D REFERENCES PART A: Global e

- Page 649 and 650:

© OECD/IEA, 2011 O&GJ (Oil and Gas

- Page 651 and 652:

© OECD/IEA, 2011 — (2011a), East

- Page 653 and 654:

RosHydroMet (2011), Report on Clima

- Page 655 and 656:

© OECD/IEA, 2011 Popel, O., et al.

- Page 657 and 658:

© OECD/IEA, 2011 Morse, R. and G.

- Page 659 and 660:

© OECD/IEA, 2011 GPOBA (Global Par

- Page 661 and 662:

IEA, OECD (Organisaon for Economic

- Page 663 and 664:

© OECD/IEA, 2011

- Page 665 and 666:

© OECD/IEA, 2011