Electronics Spectra - SMS Lucknow

Electronics Spectra - SMS Lucknow

Electronics Spectra - SMS Lucknow

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>SMS</strong> Institute of Technology, L ucknow<br />

Department of <strong>Electronics</strong> & Co mmunication<br />

of modular Robots.<br />

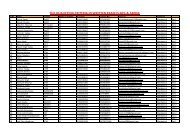

SCALING AND DESIGN<br />

PRINCIPLES<br />

A fundamental requirement of<br />

Claytronics is that the system must<br />

scale to very large numbers of interacting<br />

catoms. We have the fol lowing<br />

four design principles:<br />

1. Each catom should be self-contained,<br />

in the sense of posses s-<br />

ing everything necessary for performing<br />

its own computation,<br />

communication, sensing, actuation,<br />

locomotion, and adhesion.<br />

2. To support efficient routing o f<br />

power and avoid excessive heat<br />

dissipation, no static power<br />

3. The coordination of the catoms<br />

should be performed via local control.<br />

In particular, no computation<br />

external to the ensemble should<br />

be necessary for individual catom<br />

execution.<br />

4. For economic viability,<br />

manufacturability, and reliability,<br />

catoms should contain no moving<br />

parts.<br />

HARDWARE<br />

At the macro-scale, catoms<br />

have a diameter > 1cm and weigh<br />

many tens of grams. In light o f the<br />

design principles stated above , the<br />

only viable force that can be used to<br />

move and adhere catoms is magnetic;<br />

which sets a lower limit on th e size<br />

and weight of a catom as the m agnets<br />

have considerable weight and volume.<br />

Furthermore, the circuitr y<br />

needed for the high currents n ecessary<br />

to switch the magnets increases<br />

the weight. At this scale, it may not<br />

be possible to adhere to the “no static<br />

power” design principle. Our current<br />

prototype, as shown in Figure 2, is a<br />

system composed of catoms that only<br />

operate in two dimensions. In this<br />

case gravity holds the individual catoms<br />

to a surface and we do not hav e to<br />

deal with the adhesion problem.<br />

Much of the weight and size in a<br />

macro-scale catom comes from packaging,<br />

e.g., chip packages, pins, wires,<br />

PCBs, etc..<br />

In fact, in our planer prototy pe<br />

currently under construction we estimate<br />

that more than 20% of the<br />

weight is packaging and more t han<br />

77% goes to the magnets and th eir<br />

support circuits. This is partly because<br />

we are hand-assembling the catoms.<br />

Our next version will use machine assembly<br />

which will allow us to shrink<br />

the packaging, resulting in an estimated<br />

savings of twofold in we ight<br />

and fivefold in volume.<br />

Micro-scale catoms have diameters<br />

between 1mm and 1cm and weightless<br />

than 1 gram. Almost all packaging<br />

is eliminated and the catom is co n-<br />

structed by bonding VLSI dies directly<br />

to MEMS-based sensor and actuation<br />

dies.<br />

THE SIDE AND TOP<br />

VIEWS OF A<br />

PARTIALLY<br />

ASSEMBLED PLANAR<br />

PROTOTYPE CATOM<br />

The forces necessary to move a<br />

catom are now sufficiently small that<br />

electrostatic forces become an option.<br />

Fig. 2<br />

Macro-scale catoms would requi re<br />

electric field strengths in excess of the<br />

dielectric breakdown of air. Programmable<br />

nanofiber adhesives (PNA), can<br />

be combined with electrostatic actuation<br />

to attach catoms without using<br />

any static power. PNA is the next step<br />

in bio-mimetic adhesives which mainly<br />

use vander waals effects similar to that<br />

of the Gecko. The active components<br />

for micro-scale catoms are within the<br />

realm of current engineering practices<br />

using micro and nanoscale fabrication<br />

techniques. The container coul d be<br />

manufactured by casting a sphe rical<br />

transparent polymer film and sputtering<br />

indium-tin-oxide (ITO) ele ctrode<br />

patches on the film. The patch es of<br />

ITO would be used both to conn ect<br />

catoms for distributing power as well<br />

as used to create capacitive coupling<br />

between catoms in order to con trol<br />

their movement.<br />

The next discontinuity occurs<br />

when catoms are manufactured u s-<br />

ing nanotechnology, e.g., as in chemically<br />

assembled electronic nano-technology.<br />

In this regime, the catoms are<br />

small enough, e.g., < 10 microns in<br />

diameter, that they are aerosol. While<br />

this is currently beyond the state-ofthe-art<br />

in manufacturing further scaling<br />

of lithographic features in VLSI ,<br />

and advances in MEMS capabilities combined<br />

with advances in Nano-technology<br />

will enable the integrate d construction<br />

of such catoms.<br />

In addition to capabilities, the different<br />

regimes (macro, micro, and<br />

nano) have significantly different economics.<br />

Macro-scale catoms require the assembly<br />

of multiple parts into a single<br />

unit. We expect that this will make<br />

the realization of life-size s ynthetic<br />

reality prohibitive due to the cost per<br />

catom. The micro-scale catoms may<br />

also require assembly, but with many<br />

fewer parts, e.g., no boards and the<br />

elimination of magnets in favor of electrostatics.<br />

At this scale the entire<br />

catom will be constructed using a parallel<br />

process, e.g., photolithography.<br />

Just as VLSI-based computers are<br />

commonplace (as opposed to vacuum<br />

tube based computers), in this regime,<br />

catoms are inexpensive enough<br />

that synthetic reality, though expensive,<br />

becomes viable. For exam ple,<br />

assume a 2mm catom controlled by<br />

3mm of silicon. If half the cost is in<br />

the silicon, then, to construc t a human<br />

sized form with an average depth<br />

of 10 catoms would require app roximately<br />

1.25x10.7 catoms or less than<br />

one million dollars. In the nano regime<br />

they will become sufficiently inexpensive<br />

that synthetic reality co uld be<br />

used not only for applications such as<br />

telepario, but could be as ubiquitous<br />

as embedded processors are today.<br />

SOFTWARE<br />

The essence of claytronics—a massively<br />

distributed system composed of<br />

numerous resource-limited catoms—<br />

16 <strong>Electronics</strong> <strong>Spectra</strong>, 2010