2 - Weaver Leather

2 - Weaver Leather

2 - Weaver Leather

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Leather</strong> Shopper<br />

31<br />

Advice from Paul <strong>Weaver</strong> on<br />

Choosing the Best <strong>Leather</strong><br />

To ensure you get the right leather for your needs,<br />

I recommend you ask yourself the following questions:<br />

2<br />

3<br />

4<br />

What should my finished product<br />

look like?<br />

I recommend thinking about who will use<br />

the product and how they will use it. This<br />

is always a great way to get some insight<br />

into how the product should look and help<br />

you in choosing a compatible leather.<br />

What strength and stretch tolerances<br />

should the leather have?<br />

When strength is considered a major<br />

factor, I recommend using full thickness<br />

leathers like skirting and harness as well<br />

as unsplit latigo and bridle leathers.<br />

Unsplit leathers are stronger and do not<br />

stretch as much as split leathers because<br />

all the fibers remain intact and are<br />

not weakened by the splitting process.<br />

Please remember that leather is a<br />

natural material that’s not intended<br />

for use on products that carry a high<br />

liability or require a certification of<br />

tensile strength.<br />

Will I need to mould, case, tool,<br />

stamp, curve or carve this leather?<br />

If these techniques are to be used, a dry<br />

leather such as skirting, strap or regular<br />

bridle leather is your best choice. I do not<br />

recommend using regular bridle leather for<br />

tooling however.<br />

What finish should the leather have?<br />

When moulding, stamping or tooling,<br />

you’ll usually put your own finish on the<br />

leather. If not, you should purchase a<br />

leather that’s already been finished by the<br />

tannery. The tannery can drum dye or<br />

spray the leather in a controlled environment<br />

for a professional, consistent finish.<br />

5<br />

6<br />

7<br />

Will the product be used indoors<br />

or outdoors?<br />

For products exposed to harsh conditions,<br />

I recommend a hot stuffed leather like<br />

harness, latigo or “English” bridle leather.<br />

If you’re moulding or stamping or using a<br />

dry leather like skirting, be sure to apply<br />

oils, dyes and dressings to help prevent<br />

drying out and cracking. For products not<br />

exposed to harsh conditions, I’ve found<br />

that regular strap, bridle and chrome<br />

tanned leather usually work fine. For extra<br />

protection and long life, I recommend<br />

using leather care and conditioning<br />

products on all items.<br />

What price can I pay for my leather<br />

and still be profitable?<br />

Your selling price will largely determine<br />

what you can afford to spend on leather<br />

and still make a profit. By using the right<br />

cut and grade of leather, you give your<br />

customers the desired quality and value<br />

and still have room for your profit margin.<br />

What cut of leather is best suited for<br />

making the product?<br />

The total size of your product along with the<br />

total number of individual pieces you are<br />

making will determine the cut of leather you<br />

should use. For example, I recommend<br />

sides for products with smaller straps<br />

including 12" x 12" patterns and items that<br />

need extra length. Backs and bends are<br />

perfect for products that require the best<br />

cut of leather and the least amount of stretch.<br />

8<br />

9<br />

10<br />

How much leather do I need to<br />

complete this project?<br />

To ensure all your leather has the same<br />

weight and finish, be sure to order an<br />

adequate quantity of leather including your<br />

waste factor. By planning ahead and placing<br />

one larger order instead of many smaller<br />

orders, you may be able to take advantage<br />

of mix and match pricing and reduce your<br />

costs in the long run.<br />

Can I duplicate or improve the leather<br />

and craftsmanship of the prototype?<br />

Always make sure your customer knows<br />

what to expect and be honest about what<br />

you can and cannot do. If the job requires<br />

tools you don’t have, figure out if it’s<br />

feasible to buy them. I invite you to send<br />

us a leather swatch to make sure the leather<br />

you purchase is correct for your needs.<br />

Is this going to be a one-time custom<br />

job or an ongoing job?<br />

This will have a great influence on the<br />

price and type of leather that you buy.<br />

Your buying power is greater when you’re<br />

producing an ongoing job or a large<br />

quantity of products. When you buy in<br />

larger quantities, your cost per side goes<br />

down and any left over materials can be<br />

used for the next run of products for an<br />

ongoing job.<br />

Products in this catalog feature wholesale pricing.<br />

Due to market demands, leather prices<br />

are subject to change without notice.<br />

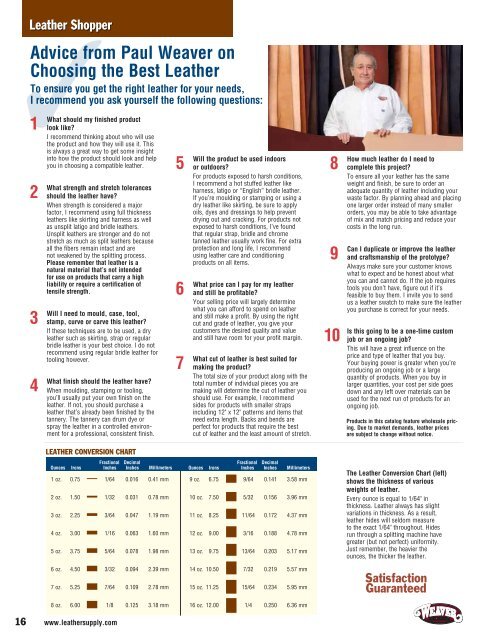

LEATHER CONVERSION CHART<br />

®<br />

Fractional Decimal<br />

Ounces Irons Inches Inches Millimeters<br />

1 oz. 0.75 1/64 0.016 0.41 mm<br />

2 oz. 1.50 1/32 0.031 0.78 mm<br />

3 oz. 2.25 3/64 0.047 1.19 mm<br />

4 oz. 3.00 1/16 0.063 1.60 mm<br />

5 oz. 3.75 5/64 0.078 1.98 mm<br />

Fractional Decimal<br />

Ounces Irons Inches Inches Millimeters<br />

9 oz. 6.75 9/64 0.141 3.58 mm<br />

10 oz. 7.50 5/32 0.156 3.96 mm<br />

11 oz. 8.25 11/64 0.172 4.37 mm<br />

12 oz. 9.00 3/16 0.188 4.78 mm<br />

13 oz. 9.75 13/64 0.203 5.17 mm<br />

The <strong>Leather</strong> Conversion Chart (left)<br />

shows the thickness of various<br />

weights of leather.<br />

Every ounce is equal to 1/64" in<br />

thickness. <strong>Leather</strong> always has slight<br />

variations in thickness. As a result,<br />

leather hides will seldom measure<br />

to the exact 1/64" throughout. Hides<br />

run through a splitting machine have<br />

greater (but not perfect) uniformity.<br />

Just remember, the heavier the<br />

ounces, the thicker the leather.<br />

®<br />

6 oz. 4.50 3/32 0.094 2.39 mm<br />

7 oz. 5.25 7/64 0.109 2.78 mm<br />

14 oz. 10.50 7/32 0.219 5.57 mm<br />

15 oz. 11.25 15/64 0.234 5.95 mm<br />

Satisfaction<br />

Guaranteed<br />

®<br />

8 oz. 6.00 1/8 0.125 3.18 mm<br />

16 oz. 12.00 1/4 0.250 6.36 mm<br />

16<br />

www.leathersupply.com<br />

®