Non destructive testing

Non destructive testing

Non destructive testing

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

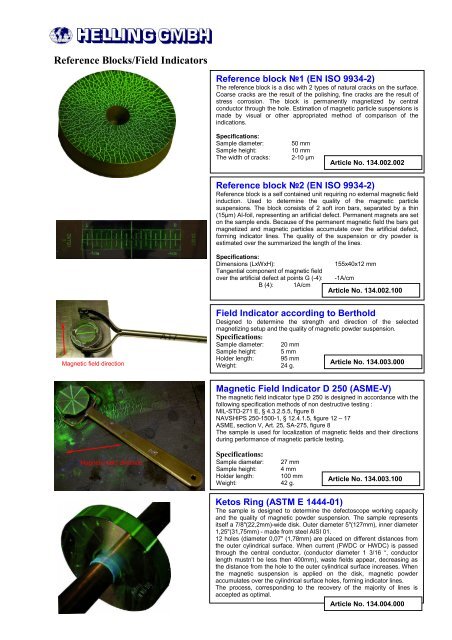

Reference Blocks/Field Indicators<br />

Reference block №1 (EN ISO 9934-2)<br />

The reference block is a disc with 2 types of natural cracks on the surface.<br />

Coarse cracks are the result of the polishing, fine cracks are the result of<br />

stress corrosion. The block is permanently magnetized by central<br />

conductor through the hole. Estimation of magnetic particle suspensions is<br />

made by visual or other appropriated method of comparison of the<br />

indications.<br />

Specifications:<br />

Sample diameter: 50 mm<br />

Sample height:<br />

10 mm<br />

The width of cracks: 2-10 µm<br />

Article No. 134.002.002<br />

Reference block №2 (EN ISO 9934-2)<br />

Reference block is a self contained unit requiring no external magnetic field<br />

induction. Used to determine the quality of the magnetic particle<br />

suspensions. The block consists of 2 soft iron bars, separated by a thin<br />

(15µm) Al-foil, representing an artificial defect. Permanent magnets are set<br />

on the sample ends. Because of the permanent magnetic field the bars get<br />

magnetized and magnetic particles accumulate over the artificial defect,<br />

forming indicator lines. The quality of the suspension or dry powder is<br />

estimated over the summarized the length of the lines.<br />

Specifications:<br />

Dimensions (LхWхH):<br />

Tangential component of magnetic field<br />

over the artificial defect at points G (-4):<br />

В (4): 1А/cm<br />

155х40х12 mm<br />

-1А/сm<br />

Article No. 134.002.100<br />

Magnetic field direction<br />

Field Indicator according to Berthold<br />

Designed to determine the strength and direction of the selected<br />

magnetizing setup and the quality of magnetic powder suspension.<br />

Specifications:<br />

Sample diameter: 20 mm<br />

Sample height: 5 mm<br />

Holder length: 95 mm<br />

Weight: 24 g.<br />

Article No. 134.003.000<br />

Magnetic Field Indicator D 250 (ASME-V)<br />

The magnetic field indicator type D 250 is designed in accordance with the<br />

following specification methods of non <strong>destructive</strong> <strong>testing</strong> :<br />

MIL-STD-271 E, § 4.3.2.5.5, figure 8<br />

NAVSHIPS 250-1500-1, § 12.4.1.5, figure 12 – 17<br />

ASME, section V, Art. 25, SA-275, figure 8<br />

The sample is used for localization of magnetic fields and their directions<br />

during performance of magnetic particle <strong>testing</strong>.<br />

Magnetic field direction<br />

Specifications:<br />

Sample diameter: 27 mm<br />

Sample height: 4 mm<br />

Holder length: 100 mm<br />

Weight: 42 g.<br />

Article No. 134.003.100<br />

Ketos Ring (ASTM E 1444-01)<br />

The sample is designed to determine the defectoscope working capacity<br />

and the quality of magnetic powder suspension. The sample represents<br />

itself a 7/8"(22,2mm)-wide disk. Outer diameter 5"(127mm), inner diameter<br />

1,25"(31,75mm) - made from steel AISI 01.<br />

12 holes (diameter 0,07" (1,78mm) are placed on different distances from<br />

the outer cylindrical surface. When current (FWDC or HWDC) is passed<br />

through the central conductor, (conductor diameter 1 3/16 “, conductor<br />

length mustn’t be less then 400mm), waste fields appear, decreasing as<br />

the distance from the hole to the outer cylindrical surface increases. When<br />

the magnetic suspension is applied on the disk, magnetic powder<br />

accumulates over the cylindrical surface holes, forming indicator lines.<br />

The process, corresponding to the recovery of the majority of lines is<br />

accepted as optimal.<br />

Article No. 134.004.000<br />

19