Non destructive testing

Non destructive testing

Non destructive testing

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

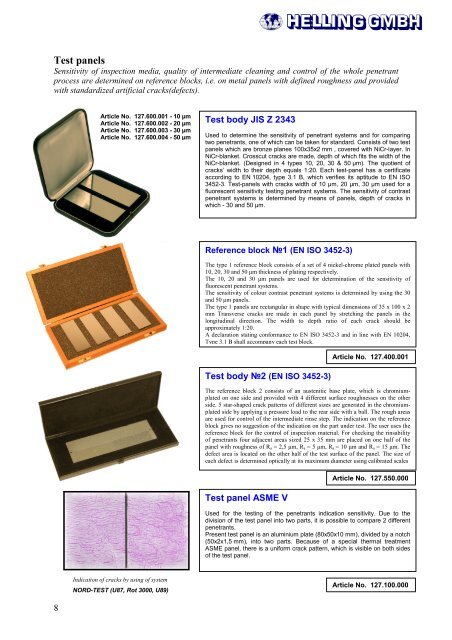

Test panels<br />

Sensitivity of inspection media, quality of intermediate cleaning and control of the whole penetrant<br />

process are determined on reference blocks, i.e. on metal panels with defined roughness and provided<br />

with standardized artificial cracks(defects).<br />

Article No. 127.600.001 - 10 µm<br />

Article No. 127.600.002 - 20 µm<br />

Article No. 127.600.003 - 30 µm<br />

Article No. 127.600.004 - 50 µm<br />

Test body JIS Z 2343<br />

Used to determine the sensitivity of penetrant systems and for comparing<br />

two penetrants, one of which can be taken for standard. Consists of two test<br />

panels which are bronze planes 100х35х2 mm , covered with NiCr-layer. In<br />

NiCr-blanket. Crosscut cracks are made, depth of which fits the width of the<br />

NiCr-blanket. (Designed in 4 types 10, 20, 30 & 50 µm). The quotient of<br />

cracks’ width to their depth equals 1:20. Each test-panel has a certificate<br />

according to EN 10204, type 3.1 B, which verifies its aptitude to EN ISO<br />

3452-3. Test-panels with cracks width of 10 µm, 20 µm, 30 µm used for a<br />

fluorescent sensitivity <strong>testing</strong> penetrant systems. The sensitivity of contrast<br />

penetrant systems is determined by means of panels, depth of cracks in<br />

which - 30 and 50 µm.<br />

Reference block №1 (EN ISO 3452-3)<br />

The type 1 reference block consists of a set of 4 nickel-chrome plated panels with<br />

10, 20, 30 and 50 µm thickness of plating respectively.<br />

The 10, 20 and 30 µm panels are used for determination of the sensitivity of<br />

fluorescent penetrant systems.<br />

The sensitivity of colour contrast penetrant systems is determined by using the 30<br />

and 50 µm panels.<br />

The type 1 panels are rectangular in shape with typical dimensions of 35 x 100 x 2<br />

mm Transverse cracks are made in each panel by stretching the panels in the<br />

longitudinal direction. The width to depth ratio of each crack should be<br />

approximately 1:20.<br />

A declaration stating conformance to EN ISO 3452-3 and in line with EN 10204,<br />

Type 3.1 B shall accompany each test block.<br />

Test body №2 (EN ISO 3452-3)<br />

Article No. 127.400.001<br />

The reference block 2 consists of an austenitic base plate, which is chromiumplated<br />

on one side and provided with 4 different surface roughnesses on the other<br />

side. 5 star-shaped crack patterns of different sizes are generated in the chromiumplated<br />

side by applying a pressure load to the rear side with a ball. The rough areas<br />

are used for control of the intermediate rinse step. The indication on the reference<br />

block gives no suggestion of the indication on the part under test. The user uses the<br />

reference block for the control of inspection material. For checking the rinsability<br />

of penetrants four adjacent areas sized 25 x 35 mm are placed on one half of the<br />

panel with roughness of R a = 2,5 µm, R a = 5 µm, R a = 10 µm and R a = 15 µm. The<br />

defect area is located on the other half of the test surface of the panel. The size of<br />

each defect is determined optically at its maximum diameter using calibrated scales<br />

Test panel ASME V<br />

Article No. 127.550.000<br />

Used for the <strong>testing</strong> of the penetrants indication sensitivity. Due to the<br />

division of the test panel into two parts, it is possible to compare 2 different<br />

penetrants.<br />

Present test panel is an aluminium plate (80х50х10 mm), divided by a notch<br />

(50х2х1,5 mm), into two parts. Because of a special thermal treatment<br />

ASME panel, there is a uniform crack pattern, which is visible on both sides<br />

of the test panel.<br />

Indication of cracks by using of system<br />

NORD-TEST (U87, Rot 3000, U89)<br />

Article No. 127.100.000<br />

8