Non destructive testing

Non destructive testing

Non destructive testing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The penetrant method of non-<strong>destructive</strong> <strong>testing</strong> is based on capillary penetration of indicator<br />

liquid (penetrant) into the surface defects (cracks, pores etc.). After intermediate cleaning and<br />

subsequent drying, a developer is applied as a thin, white layer onto the surface to be<br />

inspected. The developer “pulls” the penetrant out of the surface defects and makes them<br />

visible as coloured, linear or rounded indications. Documentation is possible by means of<br />

adhersive foil, photographic or video techniques.<br />

Penetrant <strong>testing</strong> systems<br />

Met-L-Chek, Standard Chek, Nord-Test<br />

are reliable in detecting the defects with a<br />

width down to the range of µm.<br />

Necessary condition: defects must be open<br />

to surface.<br />

Systems are also used for the leak <strong>testing</strong>.<br />

The examination of <strong>testing</strong><br />

media adequacy is done in<br />

accordance with :<br />

• AMS 2644<br />

• AMS 2647<br />

• DIN EN ISO 3452-2 (3)<br />

• ASME<br />

Penetrant inspection can accurately and<br />

easily detect surface defects independent of<br />

types, materials and surface configurations of<br />

the objects to be tested. Other methods of<br />

non <strong>destructive</strong> <strong>testing</strong>, can only be applied<br />

for these requirements with restrictions.<br />

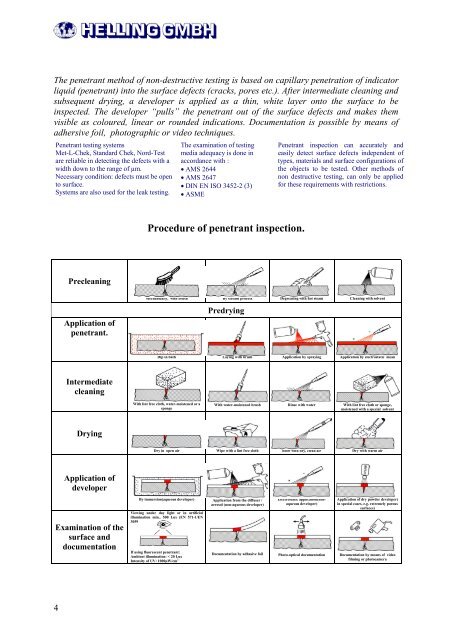

Procedure of penetrant inspection.<br />

Precleaning<br />

Application of<br />

penetrant.<br />

Mechanically, with brush By stream process Degreasing with hot steam Cleaning with solvent<br />

Predrying<br />

Dip in bath Laying with brush Application by spraying Application by electrostatic mean<br />

Intermediate<br />

cleaning<br />

With lint free cloth, water-moistened or a<br />

sponge<br />

With water-moistened brush Rinse with water With lint free cloth or sponge,<br />

moistened with a special solvent<br />

Drying<br />

Dry in open air Wipe with a lint free cloth Blow with dry, clean air Dry with warm air<br />

Application of<br />

developer<br />

Examination of the<br />

surface and<br />

documentation<br />

By immersion(aqueous developer) Application from the diffuser /<br />

aerosol (non-aqueous developer)<br />

Viewing under day light or in artificial<br />

illumination min.. 500 Lux (EN 571-1/EN<br />

3059)<br />

Electrostatic application(nonaqueous<br />

developer)<br />

Application of dry powder developer(<br />

in special cases, e.g. extremely porous<br />

surfaces)<br />

If using fluorescent penetrant:<br />

Documentation by adhasive foil<br />

Ambient illumination: < 20 Lux<br />

Photo-optical documentation Documentation by means of video<br />

Intensity of UV: 1000µW/cm 2 filming or photocamera<br />

4