Non destructive testing

Non destructive testing

Non destructive testing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Contrast (red-white) method.<br />

Areas of use:<br />

Aircrafts industry, Metallurgy, nuclear industry, Electrical engineering, Engineering, Foundry, Blanking, Shipbuilding, Medicine,<br />

Car production.<br />

Work with materials:<br />

Alloyed and plain steel, cast iron, platings, plastics*, welds, nonferrous metals, products of powder metallurgy, steatite,<br />

ceramics*, other synthetic materials.<br />

*check for adequacy<br />

MET-L-Chek, Standard- Chek & Nord-Test *<br />

Used in temperature ranges from -5 ° С to + 50 ° С. In low temperatures (from -5 ° С to + 10 ° С ) it is necessary to increase time of<br />

penetrating. One must take into account peculiar specifications according to DIN EN ISO 3452 part 2 & EN 571 part 1. For<br />

examination in higher temperatures (from +10 С to + 175 С) „Super-Chek“ was especially developed..<br />

MET-L-Chek, checked and approved<br />

DIN EN ISO 3452-2, EN 571, KWU correspond to requirements: Lloyd's Register of Shipping, Bureau Veritas, Bureau Central<br />

Hollandais, Germanischer Lloyd, MIL-I-25135/QPL-25135, AMS 2644, ASME Boiler and Pressure Vessel, ASTM E-165,<br />

ASTM-E1417, certificated NAVSEA 250-1500-1, RDT & EdF, RCC-М<br />

Standard- Chek & Nord-Test examined and approved according to :<br />

DIN EN ISO 3452-2, EN 571, KWU correspond to requirements Lloyd's Register of Shipping, Bureau Veritas, Bureau Central<br />

Hollandais, Germanischer Lloyd, MIL-I-25135/QPL-25135, AMS 2644, ASME Boiler and Pressure Vessel, ASTM E-165,<br />

ASTM-E1417.<br />

Content of sulfur is determined according to ASTM D 516-88, examination of the content of halogens (fluorine and chlorine) is<br />

determined in accordance with ASTM E 165-91, application 2, method A and ASTM E 165-91, application 3.<br />

Example of Nord-Test penetrant system<br />

Remover U87 Penetrant U88 Penetrant Red 3000 Developer U89<br />

• Environmentally<br />

safe remover on<br />

• High sensitivity<br />

• Easily cleansed with water<br />

• Ultra high level of sensitivity<br />

• Water washable<br />

• Fine-grained white<br />

powder on a spirit<br />

a solvent base. • Smells slightly<br />

• Doesn’t contain AZO-colouring agents<br />

base ,<br />

• Fumes fast. • Sensitivity according to: • Smells slightly<br />

• Doesn’t contain<br />

• Doesn’t leave<br />

dints.<br />

DIN EN ISO 3452-2 –<br />

II-level (high sensitive)<br />

Testing by luminescent method, by means of<br />

ultraviolet illumination is possible<br />

• Sensitivity according to:<br />

DIN EN ISO 3452-2 – II-level (high sensitive)<br />

aroma additives.<br />

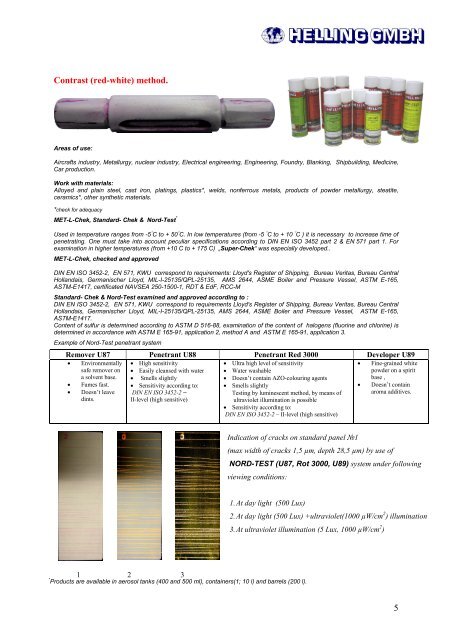

Indication of cracks on standard panel №1<br />

(max width of cracks 1,5 µm, depth 28,5 µm) by use of<br />

NORD-TEST (U87, Rot 3000, U89) system under following<br />

viewing conditions:<br />

1. At day light (500 Lux)<br />

2. At day light (500 Lux) +ultraviolet(1000 µW/cm 2 ) illumination<br />

3. At ultraviolet illumination (5 Lux, 1000 µW/cm 2 )<br />

1 2 3<br />

* Products are available in aerosol tanks (400 and 500 ml), containers(1; 10 l) and barrels (200 l).<br />

5