Non destructive testing

Non destructive testing

Non destructive testing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

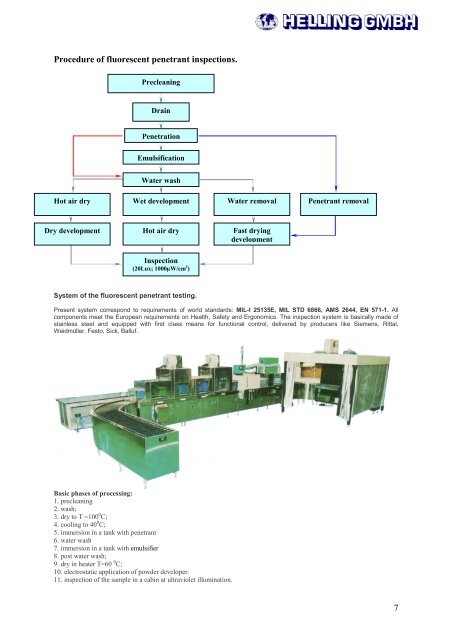

Procedure of fluorescent penetrant inspections.<br />

Precleaning<br />

Drain<br />

Penetration<br />

Emulsification<br />

Water wash<br />

Hot air dry<br />

Wet development<br />

Water removal<br />

Penetrant removal<br />

Dry development<br />

Hot air dry<br />

Fast drying<br />

development<br />

Inspection<br />

(20Lux; 1000µW/cm 2 )<br />

System of the fluorescent penetrant <strong>testing</strong>.<br />

Present system correspond to requirements of world standards: MIL-I 25135E, MIL STD 6866, AMS 2644, EN 571-1. All<br />

components meet the European requirements on Health, Safety and Ergonomics. The inspection system is basically made of<br />

stainless steel and equipped with first class means for functional control, delivered by producers like Siemens, Rittal,<br />

Weidmüller, Festo, Sick, Balluf.<br />

Basic phases of processing:<br />

1. precleaning<br />

2. wash;<br />

3. dry to Т =100 0 C;<br />

4. cooling to 40 0 С;<br />

5. immersion in a tank with penetrant<br />

6. water wash<br />

7. immersion in a tank with emulsifier<br />

8. post water wash;<br />

9. dry in heater Т=60 0 C;<br />

10. electrostatic application of powder developer.<br />

11. inspection of the sample in a cabin at ultraviolet illumination.<br />

7