Non destructive testing

Non destructive testing

Non destructive testing

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

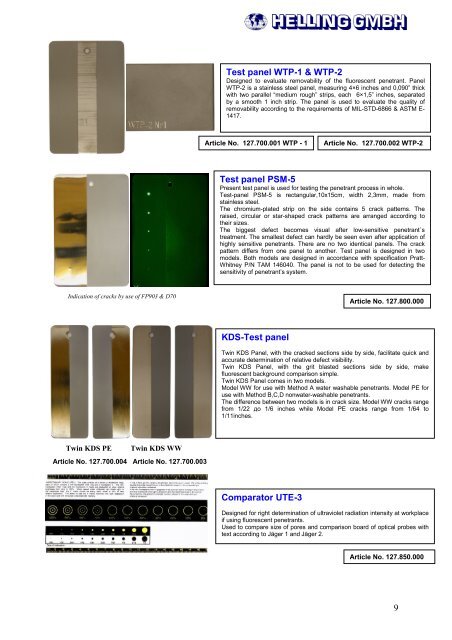

Test panel WTP-1 & WTP-2<br />

Designed to evaluate removability of the fluorescent penetrant. Panel<br />

WTP-2 is a stainless steel panel, measuring 4×6 inches and 0,090” thick<br />

with two parallel “medium rough” strips, each 6×1,5” inches, separated<br />

by a smooth 1 inch strip. The panel is used to evaluate the quality of<br />

removability according to the requirements of MIL-STD-6866 & ASTM E-<br />

1417.<br />

Article No. 127.700.001 WTP - 1<br />

Article No. 127.700.002 WTP-2<br />

Test panel PSM-5<br />

Present test panel is used for <strong>testing</strong> the penetrant process in whole.<br />

Test-panel PSM-5 is rectangular,10х15cm, width 2,3mm, made from<br />

stainless steel.<br />

The chromium-plated strip on the side contains 5 crack patterns. The<br />

raised, circular or star-shaped crack patterns are arranged according to<br />

their sizes.<br />

The biggest defect becomes visual after low-sensitive penetrant`s<br />

treatment. The smallest defect can hardly be seen even after application of<br />

highly sensitive penetrants. There are no two identical panels. The crack<br />

pattern differs from one panel to another. Test panel is designed in two<br />

models. Both models are designed in accordance with specification Pratt-<br />

Whitney P/N TAM 146040. The panel is not to be used for detecting the<br />

sensitivity of penetrant’s system.<br />

Indication of cracks by use of FP903 & D70<br />

Article No. 127.800.000<br />

KDS-Test panel<br />

Twin KDS Panel, with the cracked sections side by side, facilitate quick and<br />

accurate determination of relative defect visibility.<br />

Twin KDS Panel, with the grit blasted sections side by side, make<br />

fluorescent background comparison simple.<br />

Twin KDS Panel comes in two models.<br />

Model WW for use with Method A water washable penetrants. Model PE for<br />

use with Method B,C,D nonwater-washable penetrants.<br />

The difference between two models is in crack size. Model WW cracks range<br />

from 1/22 до 1/6 inches while Model PE cracks range from 1/64 to<br />

1/11inches.<br />

Twin KDS PE<br />

Twin KDS WW<br />

Article No. 127.700.004 Article No. 127.700.003<br />

Comparator UTE-3<br />

Designed for right determination of ultraviolet radiation intensity at workplace<br />

if using fluorescent penetrants.<br />

Used to compare size of pores and comparison board of optical probes with<br />

text according to Jäger 1 and Jäger 2.<br />

Article No. 127.850.000<br />

9