CP-122 HSE Code of Practice - PDO

CP-122 HSE Code of Practice - PDO

CP-122 HSE Code of Practice - PDO

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Petroleum Development Oman L.L.C.<br />

Document Title:<br />

Health, Safety, and Environment <strong>Code</strong> <strong>of</strong> <strong>Practice</strong><br />

Document ID<br />

<strong>CP</strong>-<strong>122</strong><br />

Document Type<br />

<strong>Code</strong> <strong>of</strong> <strong>Practice</strong><br />

Security<br />

Unrestricted<br />

Discipline<br />

MSE<br />

Document Owner<br />

MD<br />

Month and Year <strong>of</strong> Issue July 2011<br />

Version 5.0<br />

Keywords<br />

<strong>HSE</strong>, Management System<br />

Copyright: This document is the property <strong>of</strong> Petroleum Development Oman, LLC. Neither the whole<br />

nor any part <strong>of</strong> this document may be disclosed to others or reproduced, stored in a retrieval system,<br />

and/or transmitted in any form by any means (electronic, mechanical, reprographic recording, and/or<br />

otherwise) without prior written consent <strong>of</strong> the owner.

HEALTH, SAFETY AND ENVIRONMENT<br />

CODE OF PRACTICE (<strong>CP</strong>-<strong>122</strong>)<br />

<strong>PDO</strong> <strong>HSE</strong> Management System Manual<br />

Document Authorisation<br />

Document Owner Document Custodian Document Author<br />

Raoul Restucci<br />

MD<br />

July 2011<br />

Naaman Al Naamany<br />

MSEM<br />

July 2011<br />

Saeed Al Maamary<br />

MSE/5<br />

July 2011<br />

Revision History<br />

The following is a brief summary <strong>of</strong> the four most recent revisions to this document. Details <strong>of</strong> all revisions<br />

prior to these are held on file by the Document Custodian.<br />

Version<br />

No.<br />

Month and<br />

Year<br />

5.0 July 2011<br />

4.0<br />

3.0 <br />

2.0<br />

User Notes:<br />

December<br />

1998<br />

Author’s Name and<br />

Title<br />

Saeed Al Maamary<br />

MSE/5<br />

Gordon Muirhead,<br />

CSM/1<br />

Joppe Cramwinckel<br />

CSM/2<br />

Steve Williams<br />

CSM/2X<br />

Scope / Remarks<br />

Completely revised and aligned with the most<br />

recent international best practices for <strong>HSE</strong><br />

management systems, with added focus on<br />

process safety management.<br />

Revised to more closely align with EP 95-0100<br />

and <strong>HSE</strong> MS elements reduced from 10 to 8.<br />

Definition <strong>of</strong> ‘incident’ and ’environmental<br />

incident’ revised, along with minor editorial<br />

revisions.<br />

Definition <strong>of</strong> ‘significant’ revised in line with <strong>CP</strong><br />

131 – ‘Risk Management,’ along with minor<br />

editorial revisions.<br />

1. The requirements <strong>of</strong> this document are mandatory. Non-compliance shall only be authorised by a<br />

designated authority through STEP-OUT approval as described in this document.<br />

2. A controlled copy <strong>of</strong> the current version <strong>of</strong> this document is on <strong>PDO</strong>'s live link. Before making<br />

reference to this document, it is the user's responsibility to ensure that any hard copy, or<br />

electronic copy, is current. For assistance, contact the Document Custodian.<br />

3. Users are encouraged to participate in the ongoing improvement <strong>of</strong> this document by providing<br />

constructive feedback.<br />

Version 5.0 (July 2011) Page | 1

HEALTH, SAFETY AND ENVIRONMENT<br />

CODE OF PRACTICE (<strong>CP</strong>-<strong>122</strong>)<br />

<strong>PDO</strong> <strong>HSE</strong> Management System Manual<br />

Related Business Processes & CMF Documents<br />

Related Business Processes<br />

<strong>Code</strong> Business Process (EPBM 4.0)<br />

EP.01<br />

Manage Business Plan, Global Process #20 Risk Management in Projects<br />

Parent Document(s)<br />

Doc. No. Document Title<br />

PL-04 Health, Safety, and Environment Policy<br />

Other Related CMF Document(s)<br />

Doc. No. Document Title<br />

<strong>CP</strong>-107 Corporate Management Framework <strong>Code</strong> <strong>of</strong> <strong>Practice</strong><br />

<strong>CP</strong>-131 Risk and Opportunity Management <strong>Code</strong> <strong>of</strong> <strong>Practice</strong><br />

The related CMF Documents can be retrieved from the Corporate Business Control Documentation<br />

Register CMF.<br />

Version 5.0 (July 2011) Page | 2

HEALTH, SAFETY AND ENVIRONMENT<br />

CODE OF PRACTICE (<strong>CP</strong>-<strong>122</strong>)<br />

<strong>PDO</strong> <strong>HSE</strong> Management System Manual<br />

Table <strong>of</strong> Contents<br />

Document Authorisation 1<br />

Revision History 1<br />

Related Business Processes & CMF Documents 2<br />

0. INTRODUCTION 4<br />

0.1 OVERVIEW 4<br />

0.1.1 The Structure <strong>of</strong> <strong>PDO</strong>’s <strong>HSE</strong> Management System 5<br />

0.1.2 The Background and Basis <strong>of</strong> <strong>PDO</strong>’s <strong>HSE</strong> Management System 7<br />

0.1.3 Using this <strong>Code</strong> <strong>of</strong> <strong>Practice</strong> 7<br />

0.2 PURPOSE AND OBJECTIVES 9<br />

0.2.1 Purpose <strong>of</strong> <strong>PDO</strong>’s <strong>HSE</strong> Management System 9<br />

0.2.2 Objectives <strong>of</strong> the <strong>HSE</strong> Management System Manual – <strong>Code</strong> <strong>of</strong> <strong>Practice</strong> <strong>CP</strong>-<strong>122</strong> 9<br />

0.3 TARGET AUDIENCE AND DISTRIBUTION 10<br />

0.4 REFERENCE DOCUMENTS 10<br />

0.4.1 Other useful reference documents: 10<br />

0.4.2 Feedback 11<br />

1. LEADERSHIP AND COMMITMENT 12<br />

2. POLICY AND STRATEGIC OBJECTIVES 14<br />

3. ORGANISATION, RESPONSIBILITIES, RESOURCES, STANDARDS, AND DOCUMENTS 18<br />

4. HAZARDS AND EFFECTS MANAGEMENT 27<br />

5. PLANNING AND PROCEDURES 38<br />

6. IMPLEMENTATION AND OPERATION 47<br />

7. ASSURANCE: MONITORING AND AUDIT 57<br />

8. REVIEW 65<br />

9. GLOSSARY 68<br />

10. LIST OF <strong>HSE</strong>-MS DOCUMENTS 87<br />

10.1 LIST OF CODES OF PRACTICE 87<br />

10.2 LIST OF <strong>HSE</strong> COMMON PROCEDURES, SPECIFICATIONS, AND GUIDELINES 88<br />

10.3 LIST OPERATIONAL SAFETY PROCEDURES, SPECIFICATIONS, AND GUIDELINES 89<br />

10.4 LIST OF TECHNICAL SAFETY PROCEDURES, SPECIFICATIONS, AND GUIDELINES 90<br />

10.5 LIST OF OCCUPATIONAL HEALTH PROCEDURES, SPECIFICATIONS, AND GUIDELINES 92<br />

10.6 LIST OF ENVIRONMENTAL PROCEDURES, SPECIFICATIONS, AND GUIDELINES 93<br />

10.7 LIST OF EMERGENCY RESPONSE PROCEDURES, SPECIFICATIONS, AND GUIDELINES 94<br />

July 2011 Page 3

HEALTH, SAFETY AND ENVIRONMENT<br />

CODE OF PRACTICE (<strong>CP</strong>-<strong>122</strong>)<br />

<strong>PDO</strong> <strong>HSE</strong> Management System Manual<br />

0. INTRODUCTION<br />

0.1 OVERVIEW<br />

<strong>PDO</strong>‟s Health, Safety, and Environment Management System (<strong>HSE</strong> MS) is a structured approach to achieving our <strong>HSE</strong> goals,<br />

objectives, and targets, and managing the <strong>HSE</strong> risks associated with our business. <strong>PDO</strong>‟s Statement <strong>of</strong> General Business<br />

Principles (SGBP) and the <strong>PDO</strong> <strong>Code</strong> <strong>of</strong> Conduct describe how we conduct our business in terms <strong>of</strong> the fundamental<br />

expectations and standards which we set for ourselves. Central to the SGBP is the following statement regarding <strong>HSE</strong> at <strong>PDO</strong>:<br />

“The Company will endeavor to conduct its business in such a way as to protect<br />

the health and safety <strong>of</strong> its employees, its contractor employees, and other<br />

persons affected by its activities, as well as to protect the environment, minimise<br />

pollution, and seek improvement in the efficient use <strong>of</strong> natural resources.”<br />

Therefore, to be properly aligned, <strong>PDO</strong>‟s Health, Safety, and Environmental Protection Policy (PL 04) requires that a systematic<br />

approach shall be applied to <strong>HSE</strong> management in order to achieve this endeavor.<br />

<strong>PDO</strong>‟s <strong>HSE</strong> Management System provides this systematic and structured process for continual improvement in our <strong>HSE</strong><br />

performance. It concentrates, using eight (8) management system processes, on those areas and activities with the potential to<br />

have the greatest impact on harm to people and the environment, to cause damage or loss to assets, to defer oil production, to<br />

cause financial loss, and/or to adversely impact the Company‟s reputation. Continual improvement within the management<br />

system is symbolized by the cyclical arrows and is an ongoing process within the entire <strong>HSE</strong> MS.<br />

July 2011 Page 4

HEALTH, SAFETY AND ENVIRONMENT<br />

CODE OF PRACTICE (<strong>CP</strong>-<strong>122</strong>)<br />

<strong>PDO</strong> <strong>HSE</strong> Management System Manual<br />

<strong>PDO</strong>’s <strong>HSE</strong> Management System Logo - An Ancient Form is Renewed and Improved!<br />

From ancient times, the spiral-shelled ammonite has been one <strong>of</strong> nature‟s perfect forms and symbols. Over the years, it has also<br />

been adopted and has proven itself to be the trusted symbol <strong>of</strong> <strong>PDO</strong>‟s <strong>HSE</strong> Management System, or “<strong>HSE</strong> MS.”<br />

The ammonite shell has particular significance. Its shape is based on the naturally occurring Fibonacci number sequence,<br />

continually spiraling outwards with systematic precision and accuracy.<br />

Also, as a logo for the Company, the stylized ammonite is individual, easily recognized, and is distinctly <strong>PDO</strong>‟s. The remains <strong>of</strong><br />

life on earth from ancient times helped form the varied hydrocarbon resources upon which <strong>PDO</strong> depends, with ammonites and<br />

other fossils leading geologists back to ancient rock deposits in their search for oil and gas.<br />

The logo <strong>of</strong> <strong>PDO</strong>‟s <strong>HSE</strong> Management System is also distinctly <strong>PDO</strong>. Its colors represent each process <strong>of</strong> the Management<br />

System. The spiraling outward <strong>of</strong> the ammonite form evokes <strong>PDO</strong>‟s quest for continual and systematic improvement in <strong>HSE</strong><br />

performance.<br />

0.1.1 The Structure <strong>of</strong> <strong>PDO</strong>‟s <strong>HSE</strong> Management System<br />

No company can operate effectively without a management system and controls in some form. A management system and its<br />

associated controls are the structured means used to obtain reasonable assurance <strong>of</strong> achieving the Company‟s goals,<br />

objectives, and targets (including its <strong>HSE</strong> goals, objectives, and targets). These controls should be well thought out and<br />

designed, clear, and systematic, so as to be appropriate to the business. Without an appropriate management and business<br />

control framework, the Company and all involved stakeholders with it may be subject to an unacceptable level <strong>of</strong> risk.<br />

Internationally accepted standards and current<br />

good practices have five basic processes <strong>of</strong><br />

business control, typically expressed in a<br />

“Continual Improvement Model” or loop, as follows:<br />

1. Policy<br />

2. Planning<br />

3. Implementation and Operation<br />

4. Checking<br />

5. Review.<br />

<strong>PDO</strong> has adopted these five processes <strong>of</strong> business<br />

control and has developed an overall business<br />

control framework.<br />

This is the Corporate Management Framework or<br />

“CMF.” This is the highest level document in <strong>PDO</strong>‟s<br />

overall management system and describes the way<br />

<strong>PDO</strong> manages its business. <strong>PDO</strong>‟s documentation<br />

hierarchy and framework can be seen in Appendix<br />

One <strong>of</strong> this chapter.<br />

<strong>PDO</strong>‟s <strong>HSE</strong> Management System is an important part <strong>of</strong> <strong>PDO</strong>‟s overall business control framework, and this can be seen in<br />

detail in <strong>CP</strong>-107, the Corporate Management Framework. Table One on the next page gives an overview <strong>of</strong> the structure,<br />

associated documentation hierarchy, and documentation definitions <strong>of</strong> <strong>PDO</strong>‟s <strong>HSE</strong> Management System.<br />

July 2011 Page 5

HEALTH, SAFETY AND ENVIRONMENT<br />

CODE OF PRACTICE (<strong>CP</strong>-<strong>122</strong>)<br />

<strong>PDO</strong> <strong>HSE</strong> Management System Manual<br />

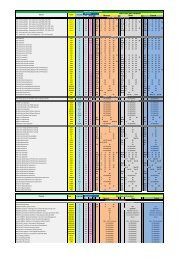

Table One: <strong>PDO</strong>’s Documentation Hierarchy, Definitions, and <strong>HSE</strong> Management System<br />

DOCUMENTATION<br />

HIERACHY AND DEFINITIONS<br />

POLICY<br />

A document broadly defining <strong>PDO</strong>‟s expectations<br />

and requirements.<br />

↕<br />

CODE OF PRACTICE<br />

A high level document that specifies the overall<br />

approach and procedure for performing a business<br />

process / activity, and which states the minimum<br />

requirements expected from employees,<br />

contractors, and/or other relevant stakeholders.<br />

↕<br />

<strong>HSE</strong><br />

Management<br />

System Manual<br />

(<strong>CP</strong>-<strong>122</strong>)<br />

Leadership and<br />

Commitment<br />

Policy and<br />

Strategic<br />

Objectives<br />

Organisation,<br />

Responsibilities,<br />

Resources,<br />

Standards, and<br />

Documents<br />

“Key” <strong>HSE</strong> Management System<br />

Documentation (i.e., high-level hyperlinked<br />

documents in this manual)<br />

PL-04 – Health, Safety, and Environmental Protection<br />

<strong>CP</strong>-107 – Corporate Management Framework<br />

Statement <strong>of</strong> General Business Principles (SGBP)<br />

PL-04 – Health, Safety, and Environmental Protection<br />

PL-10 – Security Policy & Emergency Response Policy<br />

<strong>CP</strong>-100 – Policy Approval<br />

<strong>CP</strong>-107 – Corporate Management Framework<br />

Statement <strong>of</strong> General Business Principles (SGBP)<br />

PL-03 – Risk and Internal Control Policy<br />

PL-04 – <strong>HSE</strong> Policy<br />

PL-05 – Governance Policy<br />

PL-08 – Commercial Policy<br />

PL-09 – Human Resources Policy<br />

<strong>CP</strong>-100 – Policy Approval<br />

<strong>CP</strong>-102 – Corporate Document Management<br />

<strong>CP</strong>-107 – Corporate Management Framework<br />

<strong>CP</strong>-111 – Relationship With Stakeholders<br />

<strong>CP</strong>-123 – Emergency Procedures, Part I<br />

<strong>CP</strong>-129 – Contracting and Procurement<br />

<strong>CP</strong>-141 – Use <strong>of</strong> Concession Land by Third Parties<br />

<strong>CP</strong>-162 – Internal Communication<br />

Asset Level Business Control<br />

Documents and Records (i.e.,<br />

examples <strong>of</strong> key documents and<br />

associated records)<br />

Self Assessment Questionnaires (SAQ)<br />

Statements <strong>of</strong> Fitness<br />

<strong>HSE</strong> Plans<br />

Evidence <strong>of</strong> Leadership Tours, inspections,<br />

communication activities, etc.<br />

<strong>HSE</strong> Legislation<br />

<strong>HSE</strong> licenses / approvals / permits<br />

Etc.<br />

Job descriptions<br />

Minutes <strong>of</strong> committee and other meetings<br />

Training plans<br />

Contract documents<br />

Monthly <strong>HSE</strong> reports<br />

Competency / training records<br />

Reports to external stakeholders<br />

Etc.<br />

inputs<br />

←<br />

←<br />

←<br />

PROCEDURE<br />

A document that specifies the way a work process /<br />

activity / task is to be performed, describing why<br />

(purpose), what (scope), who (responsibility), when<br />

(frequency), how (tasks involved), and how many /<br />

how much (specifications).<br />

Hazards and<br />

Effects<br />

Management<br />

(HEMP)<br />

PL-03 – Risk and Internal Control<br />

PL-04 – Health, Safety, and Environmental Protection<br />

<strong>CP</strong>-131 – Risk and Opportunity Management<br />

Hazards & Effects Registers<br />

<strong>HSE</strong> Cases<br />

Environmental Impact Assessments<br />

Integrated Impact Assessments<br />

Etc.<br />

←<br />

↕<br />

SPECIFICATION<br />

The specific requirements that are mandatory – with<br />

respect to performance, implementation,<br />

monitoring, and reporting. A specification can<br />

apply to materials, products, activities, and/or<br />

services.<br />

↕<br />

GUIDELINES<br />

A non-mandatory document providing<br />

supplementary information about acceptable<br />

methods for implementing requirements found in<br />

policies, business processes, procedures, work<br />

instructions, etc.<br />

↕<br />

RECORDS<br />

A document containing information with respect to<br />

results achieved and/or providing evidence <strong>of</strong><br />

activities performed. (A record is an “output”<br />

document and it typically cannot be revised or<br />

altered. Records are typically created from forms<br />

and templates).<br />

Planning and<br />

Procedures<br />

Implementation<br />

and Operation<br />

Assurance:<br />

Monitoring and<br />

Audit<br />

Review<br />

PL-03 – Risk and Internal Control<br />

PL-04 – Health, Safety, and Environmental Protection<br />

PL-09 – Human Resources<br />

PL-10 – Security and Emergency Response<br />

PL-11 – Asset Integrity and Disposal<br />

<strong>CP</strong>-107 – Corporate Management Framework<br />

<strong>CP</strong>-114 – Maintenance & Integrity Management<br />

<strong>CP</strong>-115 – Operation <strong>of</strong> Surface Product Flow Assets<br />

<strong>CP</strong>-117 – Project Engineering<br />

<strong>CP</strong>-118 – Well Lifecycle Integrity<br />

<strong>CP</strong>-123 – Emergency Response Documents Part I<br />

<strong>CP</strong>-126 – Personnel and Asset Security<br />

<strong>CP</strong>-136 – Planning in <strong>PDO</strong><br />

PL-04 – Health, Safety, and Environmental Protection<br />

PL-06 – Information Management and Internal<br />

Communication<br />

<strong>CP</strong>-114 – Maintenance and Integrity Management<br />

<strong>CP</strong>-115 – Operate Surface Product Flow Assets<br />

<strong>CP</strong>-117 – Project Engineering<br />

<strong>CP</strong>-118 – Well Lifecycle Integrity<br />

<strong>CP</strong> 123 – Emergency Response Documents, Part I<br />

<strong>CP</strong>-136 – Planning in <strong>PDO</strong><br />

PL-03 – Risk and Internal Control<br />

PL-04 – Health, Safety, and Environmental Protection<br />

PL-06 – Information Management and Internal<br />

Communication<br />

PL-03 – Risk and Internal Control<br />

PL-04 – Health, Safety, and Environmental Protection<br />

<strong>CP</strong>-100 – Policy Approval<br />

<strong>CP</strong>-107 – Corporate Management Framework<br />

<strong>CP</strong>-123 – Emergency Response Documents Part I<br />

Asset Manager Mandate(s)<br />

Emergency Response Documents Part II<br />

Specific Contingency Plans<br />

Asset Level <strong>HSE</strong> Plans<br />

Work Permit Procedure<br />

Operational Control documents / procedures<br />

/ work instructions<br />

Etc.<br />

All relevant Asset operational control<br />

procedures<br />

Work Permit Procedure<br />

Management <strong>of</strong> Change Procedure(s)<br />

Etc.<br />

Audit reports<br />

Audit follow-up Action Plans<br />

Monitoring data<br />

Non-compliance report forms<br />

Corrective action plans<br />

Incident reports<br />

Follow-up Action Plans<br />

Etc.<br />

Minutes <strong>of</strong> management review meetings<br />

Etc.<br />

←<br />

outputs<br />

→<br />

→<br />

→<br />

July 2011 Page 6

HEALTH, SAFETY AND ENVIRONMENT<br />

CODE OF PRACTICE (<strong>CP</strong>-<strong>122</strong>)<br />

<strong>PDO</strong> <strong>HSE</strong> Management System Manual<br />

0.1.2 The Background and Basis <strong>of</strong> <strong>PDO</strong>‟s <strong>HSE</strong> Management System<br />

This revision to the <strong>HSE</strong> Management System further advances <strong>PDO</strong>‟s continual improvement in <strong>HSE</strong> and its overall Corporate<br />

Management Framework (CMF), a structure and <strong>Code</strong> <strong>of</strong> <strong>Practice</strong> document developed to provide clarity and direction on the<br />

principles by which <strong>PDO</strong> manages its business. <strong>PDO</strong>‟s <strong>HSE</strong> Management System fits within the CMF. As such, the <strong>HSE</strong><br />

Management System is aligned and meets stakeholder aspirations and expectations in that it delivers compliance with the<br />

following:<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Omani Law: While there is no specific legal requirement for <strong>PDO</strong> to have an <strong>HSE</strong> Management System in place, Omani<br />

Law essentially requires that many <strong>of</strong> the key processes <strong>of</strong> a Management System are in place.<br />

<strong>PDO</strong> Business Policies: <strong>PDO</strong>‟s Business Policies communicate our intentions and expectations for achieving stated<br />

Business Objectives. <strong>PDO</strong>‟s <strong>HSE</strong> Policy requires that a systematic approach to <strong>HSE</strong> management shall be applied.<br />

The ISO 14001 standard for environmental management systems.<br />

The OHSAS 18001 specification for occupational health and safety management systems.<br />

The Center for Chemical Process Safety (C<strong>CP</strong>S - 20 Elements for Process Safety).<br />

Shell HSSE & SP Control Framework, Version 2, 2009, Shell Group Standards for Health, Security, Safety, the Environment<br />

& Social Performance.<br />

<strong>PDO</strong>‟s Management System hierarchy <strong>of</strong> documents (The Corporate Management Framework [CMF], Policies, <strong>Code</strong>s <strong>of</strong><br />

<strong>Practice</strong>, Procedures, Specifications, Guidelines, and Records).<br />

The ongoing and future vision for <strong>PDO</strong>‟s <strong>HSE</strong> Management System is the systematic review, with revisions as necessary,<br />

leading to the continual improvement <strong>of</strong> measures taken to protect the health, safety, and environment <strong>of</strong> those that may be<br />

affected by the activities <strong>of</strong> <strong>PDO</strong>. This vision is also part <strong>of</strong> <strong>PDO</strong>‟s management commitment so as to ensure the suitability,<br />

adequacy, and effectiveness <strong>of</strong> the <strong>HSE</strong> Management System. See Table Two – ALIGNMENT OF <strong>PDO</strong>‟S <strong>HSE</strong> MANAGEMENT<br />

SYSTEM PROCESSES WITH 1SO 14001, OHSAS 18001, C<strong>CP</strong>S PSM, and the SHELL HSSE & SP CONTROL FRAMEWORK<br />

on the next page for details.<br />

0.1.3 Using this <strong>Code</strong> <strong>of</strong> <strong>Practice</strong><br />

Language<br />

In this document the recommendations for a course <strong>of</strong> action are made with varying degrees <strong>of</strong> emphasis and mandate. As a<br />

rule:<br />

<br />

<br />

<br />

'shall' / „must‟ indicates a required course <strong>of</strong> action at all times, with mandatory status within <strong>PDO</strong>, and a good practice.<br />

'should' indicates a preferred course <strong>of</strong> action, and a best practice.<br />

'may' / „can‟ indicates a possible, optional, and/or supplementary course <strong>of</strong> action.<br />

In this document the collective expressions <strong>of</strong> <strong>PDO</strong> are sometimes used for convenience in contexts where reference is made to<br />

the specific asset and/or for contractors in general. These expressions are used where no useful purpose is served by identifying<br />

the particular asset and/or contractor(s).<br />

Application<br />

In general this <strong>Code</strong> <strong>of</strong> <strong>Practice</strong> is applicable to all <strong>PDO</strong> operations, assets, and facilities, employees, contractors, and other<br />

relevant stakeholders. Should any significant deviations be made from the recommendations in this document, then users are<br />

required to inform <strong>PDO</strong> <strong>of</strong> the nature and justification for these if it is intended that the deviations are to be permanent.<br />

Feedback<br />

The content <strong>of</strong> the <strong>HSE</strong> MS is not static, but a growing and improving collection <strong>of</strong> <strong>HSE</strong> expertise. Consequently, users are<br />

invited to comment on the content to <strong>PDO</strong> and to suggest changes and additional material which they consider would be useful<br />

for inclusion in future revisions. Please refer such comments to MSE52 using the Feedback Form on Page 11.<br />

July 2011 Page 7

HEALTH, SAFETY AND ENVIRONMENT<br />

CODE OF PRACTICE (<strong>CP</strong>-<strong>122</strong>)<br />

<strong>PDO</strong> <strong>HSE</strong> Management System Manual<br />

Table Two: ALIGNMENT OF <strong>PDO</strong>’S <strong>HSE</strong> MANAGEMENT SYSTEM PROCESSES WITH 1SO 14001,<br />

OHSAS 18001, C<strong>CP</strong>S PSM, and the SHELL HSSE & SP CONTROL FRAMEWORK<br />

<strong>HSE</strong> Management<br />

System Manual /<br />

<strong>CP</strong>-<strong>122</strong><br />

ISO 14001 : 2004 OHSAS 18001 : 2007 C<strong>CP</strong>S PSM<br />

Shell HSSE & SP Control<br />

Framework,<br />

Version 2, 2009<br />

Process / Chapter 1<br />

Leadership and<br />

Commitment<br />

No explicit reference.<br />

4.4.1 Resources, Roles,<br />

Responsibility, Accountability,<br />

and Authority<br />

1. Process Safety Culture 1. Leadership and Commitment<br />

Process / Chapter 2<br />

Policy and Strategic<br />

Objectives<br />

4.1 General Requirements<br />

4.2 Environmental Policy<br />

4.3.2 Legal and Other<br />

Requirements<br />

4.1 General Requirements<br />

4.2 OH&S Policy<br />

4.3.2 Legal and Other<br />

Requirements<br />

2. Compliance with Standards 2. Policy and Objectives<br />

Process / Chapter 3<br />

Organisation,<br />

Responsibilities,<br />

Resources,<br />

Standards, and<br />

Documents<br />

4.4.1 Resources, Roles,<br />

Responsibility, and Authority<br />

4.4.2 Competence, Training, and<br />

Awareness<br />

4.4.3 Communication<br />

4.4.4 Documentation<br />

4.4.5 Control <strong>of</strong> Documents<br />

4.4.1 Resources, Roles,<br />

Responsibility,<br />

Accountability, and Authority<br />

4.4.2 Competence, Training, and<br />

Awareness<br />

4.4.3 Communication, Participation,<br />

and Consultation<br />

4.4.4 Documentation<br />

4.4.5 Control <strong>of</strong> Documents<br />

3. Process Safety Competency<br />

4. Workforce Involvement<br />

5. Stakeholder Outreach<br />

6. Process Knowledge<br />

Management<br />

12. Training and Performance<br />

Assurance<br />

15. Conduct <strong>of</strong> Operations<br />

3. Organisation, Responsibilities,<br />

Resources (including<br />

Competence)<br />

Process / Chapter 4<br />

Hazards and Effects<br />

Management<br />

4.3.1 Environmental Aspects<br />

4.4.7 Emergency Preparedness<br />

and Response<br />

4.3.1 Hazard Identification, Risk<br />

Assessment, and<br />

Determining Controls<br />

4.4.7 Emergency Preparedness<br />

and Response<br />

6. Process Knowledge<br />

Management<br />

7. Hazards Identification and Risk<br />

Analysis<br />

14. Operational Readiness<br />

16. Emergency Management<br />

4. Risk Management<br />

(including Managing Risk<br />

and Risk Assessment Matrix<br />

[RAM])<br />

Process / Chapter 5<br />

Planning and<br />

Procedures<br />

4.3.3 Objectives, Targets, and<br />

Programme(s)<br />

4.4.6 Operational Control<br />

4.4.7 Emergency Preparedness<br />

and Response<br />

4.3.3 Objectives and Programme(s)<br />

4.4.6 Operational Control<br />

4.4.7 Emergency Preparedness<br />

and Response<br />

8. Operating Procedures<br />

9. Safe Work <strong>Practice</strong>s<br />

10. Asset Integrity and Reliability<br />

11. Contractor Management<br />

13. Management <strong>of</strong> Change<br />

15. Conduct <strong>of</strong> Operations<br />

16. Emergency Management<br />

5. Planning and Procedures<br />

(including Emergency<br />

Response, Management <strong>of</strong><br />

Change, Permit to Work,<br />

Planning and Procedures)<br />

Process / Chapter 6<br />

Implementation and<br />

Operation<br />

4.4.6 Operational Control<br />

4.5.4 Control <strong>of</strong> Records<br />

4.4.6 Operational Control<br />

4.5.4 Control <strong>of</strong> Records<br />

6. Process Knowledge<br />

Management<br />

8. Operating Procedures<br />

9. Safe Work <strong>Practice</strong>s<br />

10. Asset Integrity and Reliability<br />

11. Contractor Management<br />

13. Management <strong>of</strong> Change<br />

15. Conduct <strong>of</strong> Operations<br />

6. Implementation Monitoring and<br />

Reporting (specifically –<br />

Implement)<br />

Process / Chapter 7<br />

Assurance:<br />

Monitoring and Audit<br />

4.5.1 Monitoring and Measurement<br />

4.5.2 Evaluation <strong>of</strong> Compliance<br />

4.5.3 Nonconformity, Corrective<br />

Action & Preventive Action<br />

4.5.4 Internal Audit<br />

4.5.1 Performance Measurement<br />

and Monitoring<br />

4.5.2 Evaluation <strong>of</strong> Compliance<br />

4.5.3 Incident Investigation,<br />

Nonconformity, Corrective<br />

Action Preventive & Action<br />

4.5.5 Internal Audit<br />

17. Incident Investigation<br />

18. Measurement and Metrics<br />

19. Auditing<br />

6. Implementation Monitoring<br />

and Reporting (specifically –<br />

Incident Investigation and<br />

Learning, and Performance<br />

Monitoring and Reporting)<br />

7. Assurance<br />

Process / Chapter 8<br />

Review<br />

4.6 Management Review 4.6 Management Review<br />

20. Management Review and<br />

Continuous Improvement<br />

8. Management Review<br />

July 2011 Page 8

HEALTH, SAFETY AND ENVIRONMENT<br />

CODE OF PRACTICE (<strong>CP</strong>-<strong>122</strong>)<br />

<strong>PDO</strong> <strong>HSE</strong> Management System Manual<br />

<strong>HSE</strong> MS Manual Format<br />

Each <strong>HSE</strong> MS Process chapter contains the following standard sections and format, in order to explain and simplify its content<br />

for the reader:<br />

1. OVERVIEW: This explains the “WHY” or purpose <strong>of</strong> the Process in the overall <strong>HSE</strong> MS.<br />

2. REQUIREMENTS: This explains “WHAT” is required to be implemented in the <strong>HSE</strong> MS Process.<br />

3. PROCEDURES: This explains “HOW” the <strong>HSE</strong> MS Process / activity is to be implemented or conducted.<br />

4. REFERENCES: This explains to the reader “WHERE” to look for further implementation information in other <strong>PDO</strong><br />

documentation.<br />

0.2 PURPOSE AND OBJECTIVES<br />

0.2.1 Purpose <strong>of</strong> <strong>PDO</strong>‟s <strong>HSE</strong> Management System<br />

The purpose <strong>of</strong> <strong>PDO</strong>‟s Health, Safety, and Environment Management System is to manage threats, hazards, events, and effects<br />

to health, safety, and the environment in a systematic and structured way. The management <strong>of</strong> these involves a systematic<br />

process <strong>of</strong> risk identification, assessment / evaluation, control, monitoring, and recovery where necessary.<br />

The <strong>HSE</strong> Management System also sets performance standards for managing health, safety, and environment, which will be<br />

assessed and continually improved by a systematic approach to performance monitoring, audits, assessments, and reviews.<br />

0.2.2 Objectives <strong>of</strong> the <strong>HSE</strong> Management System Manual – <strong>Code</strong> <strong>of</strong> <strong>Practice</strong> <strong>CP</strong>-<strong>122</strong><br />

The objectives <strong>of</strong> this <strong>HSE</strong> Management System Manual or CoP <strong>122</strong> are:<br />

<br />

<br />

<br />

<br />

<br />

To inform, by providing all employees, contractors, and other relevant stakeholders with a concise, comprehensive, and<br />

structured description <strong>of</strong> all aspects <strong>of</strong> <strong>PDO</strong>‟s <strong>HSE</strong> Management System. As such, the Manual / CoP describes the<br />

„processes‟ for managing <strong>HSE</strong> at the corporate level, and within any Asset Team. It also acts as the main reference<br />

framework for the various documents that make up the <strong>HSE</strong> Management System.<br />

To illustrate the linkages between the <strong>HSE</strong> Management System and the Business Control Framework used to manage<br />

<strong>PDO</strong>‟s Asset Teams.<br />

To provide a high level document which systematically addresses achievement <strong>of</strong>, and alignment to <strong>PDO</strong>‟s Three <strong>HSE</strong><br />

Golden Rules: 1) Comply with the law, standards, and procedures; 2) Intervene in unsafe or non-compliant actions; and 3)<br />

Respect our neighbours.<br />

To provide a high level document which systematically addresses achievement <strong>of</strong>, and alignment to <strong>PDO</strong>‟s Life Saving Rules.<br />

To inform and communicate <strong>PDO</strong>‟s <strong>HSE</strong> Management System to employees, contractors, and other relevant stakeholders in<br />

a way that is interesting and easy to understand. It does this through color coding each chapter to represent each process<br />

<strong>of</strong> the <strong>HSE</strong> Management System and matches the colors on the <strong>HSE</strong> Management System logo, as well as formatting each<br />

chapter in a standardized way as defined above.<br />

July 2011 Page 9

HEALTH, SAFETY AND ENVIRONMENT<br />

CODE OF PRACTICE (<strong>CP</strong>-<strong>122</strong>)<br />

<strong>PDO</strong> <strong>HSE</strong> Management System Manual<br />

0.3 TARGET AUDIENCE AND DISTRIBUTION<br />

<strong>PDO</strong>‟s <strong>HSE</strong> Management System applies to all <strong>PDO</strong> activities (including those conducted by employees, contractors, suppliers,<br />

and/or other relevant stakeholders). The main target audience for this <strong>HSE</strong> Management System Manual is all <strong>PDO</strong> employees<br />

and contractors; therefore it is designed for the widest circulation possible within <strong>PDO</strong>.<br />

Contractors, suppliers, and other relevant stakeholders may also be considered as a „target audience‟ in that they may wish to<br />

use this Manual / CoP as guidance in developing their own <strong>HSE</strong> Management Systems to meet <strong>PDO</strong> requirements.<br />

Distribution <strong>of</strong> this document is controlled by the Document Owner, the Corporate <strong>HSE</strong> Manager. <strong>PDO</strong>‟s Electronic Document<br />

Management System (EDMS) is used for document control.<br />

This document shall be reviewed annually by the Document Owner. The objective <strong>of</strong> this document review is to determine the<br />

ongoing suitability, adequacy, and effectiveness <strong>of</strong> <strong>CP</strong>-<strong>122</strong>, and to identify any needs for change, updating, and/or continual<br />

improvement. This can be included in or as part <strong>of</strong> the <strong>PDO</strong> <strong>HSE</strong>-MS Management Review process as described in Process 8.<br />

0.4 REFERENCE DOCUMENTS<br />

Reference documents used in the writing <strong>of</strong> this Introduction, which may be used for more information:<br />

<strong>PDO</strong> Policies PL-04 – Health, Safety, and Environmental Protection PL 04<br />

<strong>PDO</strong> <strong>Code</strong>s <strong>of</strong> <strong>Practice</strong><br />

<strong>CP</strong>-102 – Corporate Document Management<br />

<strong>CP</strong>-107 – Corporate Management Framework<br />

<strong>CP</strong> 102<br />

<strong>CP</strong> 107<br />

<strong>PDO</strong> <strong>HSE</strong> Procedures No direct link exists and/or is required. --<br />

<strong>PDO</strong> <strong>HSE</strong> Specifications No direct link exists and/or is required. --<br />

<strong>PDO</strong> <strong>HSE</strong> Guidelines No direct link exists and/or is required. --<br />

Other <strong>PDO</strong> Documents<br />

Statement <strong>of</strong> General Business Principles (SGBP)<br />

<strong>PDO</strong> <strong>Code</strong> <strong>of</strong> Conduct<br />

January 2007<br />

April 2011<br />

Shell Group Documents<br />

Shell HSSE & SP Control Framework, Version 2, (Shell Group Standards for<br />

Health, Security, Safety, the Environment & Social Performance)<br />

December 2009<br />

Other Documents<br />

Occupational Health and Safety Assessment Series<br />

Environmental Management Systems –Specification with Guidance for Use<br />

Quality Management Systems – Requirements<br />

The Center for Chemical Process Safety (C<strong>CP</strong>S - www.aiche.org/ccps)<br />

OHSAS 18001:2007<br />

ISO 14001:2004<br />

ISO 9001:2008<br />

C<strong>CP</strong>S 2010<br />

0.4.1 Other useful reference documents:<br />

Please refer to the individual <strong>HSE</strong> MS Process for further reference documents and their hyper-links, and/or the Glossary for<br />

a complete listing.<br />

July 2011 Page 10

HEALTH, SAFETY AND ENVIRONMENT<br />

CODE OF PRACTICE (<strong>CP</strong>-<strong>122</strong>)<br />

<strong>PDO</strong> <strong>HSE</strong> Management System Manual<br />

0.4.2 Feedback<br />

FEEDBACK FORM: In the spirit <strong>of</strong> continual improvement, <strong>CP</strong>-<strong>122</strong> will be periodically reviewed and updated as necessary to<br />

incorporate corrections and improvements identified by users. <strong>PDO</strong> would very much welcome your comments and suggestions<br />

to assist this process.<br />

If you would like to make any suggestions for improvement please can you send your comments on an email to MSE52,<br />

organizing the information in a format similar to that shown below.<br />

<strong>CP</strong>-<strong>122</strong> Reference / Section<br />

Suggestions for Improvement<br />

Appendix One: <strong>PDO</strong> Documentation Hierarchy and Framework<br />

July 2011 Page 11

HEALTH, SAFETY AND ENVIRONMENT<br />

CODE OF PRACTICE (<strong>CP</strong>-<strong>122</strong>)<br />

<strong>PDO</strong> <strong>HSE</strong> Management System Manual<br />

1. LEADERSHIP AND COMMITMENT<br />

1.1 OVERVIEW<br />

<strong>PDO</strong> promotes a strong culture <strong>of</strong> commitment to <strong>HSE</strong> management through:<br />

Its core values <strong>of</strong> honesty, integrity, and respect for people,<br />

Valuing trust and pride in <strong>PDO</strong>,<br />

Openness, teamwork, and pr<strong>of</strong>essionalism.<br />

The leadership in <strong>PDO</strong> is responsible to promote, discuss, provide, and set proper <strong>HSE</strong> examples and behaviours. <strong>PDO</strong><br />

leaders demonstrate their commitment through various walk-the-talk activities.<br />

Leaders / Leadership<br />

A leader is a person who motivates a group <strong>of</strong> people towards achieving a common goal. In <strong>PDO</strong>, there are leaders at all levels<br />

from the Managing Director to the Supervisor. Leadership is the collective function <strong>of</strong> all leaders.<br />

<strong>HSE</strong> Culture<br />

<strong>HSE</strong> culture is the combination <strong>of</strong> <strong>HSE</strong> systems, peoples‟ behaviours, and attitudes.<br />

1.2 REQUIREMENTS<br />

Leaders at all levels in <strong>PDO</strong> shall provide strong<br />

and visible leadership by setting a personal<br />

example to promote a culture in which all<br />

employees and company contractors share a<br />

commitment to <strong>HSE</strong>.<br />

The functions and responsibilities <strong>of</strong> the<br />

leadership shall include the following, within the<br />

limitations <strong>of</strong> their job responsibilities:<br />

1.2.1 Visibility<br />

Participating in <strong>HSE</strong> activities (e.g., training,<br />

behaviour observation, commendation and<br />

coaching schemes, industry and contractor<br />

workshops, forums, and conferences, and<br />

audits / assessments).<br />

Putting <strong>HSE</strong> issues high on the agenda <strong>of</strong> the meetings they are chairing.<br />

Participating in the review <strong>of</strong> performance against all <strong>HSE</strong> plans, goals, objectives, and/or targets.<br />

Providing immediate and visible response and involvement in the case <strong>of</strong> an incident or any other disruption to normal<br />

business.<br />

Seeking internal and external views on <strong>HSE</strong>, and using and managing this knowledge in a meaningful manner.<br />

Recognizing individual and group <strong>HSE</strong> achievements, using positive behaviour reinforcement techniques, and coaching<br />

for correcting behaviour as necessary.<br />

1.2.2 Goals, Objectives, and Targets<br />

Jointly developing and discussing with <strong>PDO</strong> employees and contractors <strong>HSE</strong> „leading‟ and „lagging‟ improvement goals,<br />

objectives, targets, and/or other indicators / KPIs.<br />

Ensuring staff have a balance <strong>of</strong> <strong>HSE</strong> „leading‟ and „lagging‟ goals, objectives, and/or targets in their performance<br />

appraisals.<br />

July 2011 Page 12

HEALTH, SAFETY AND ENVIRONMENT<br />

CODE OF PRACTICE (<strong>CP</strong>-<strong>122</strong>)<br />

<strong>PDO</strong> <strong>HSE</strong> Management System Manual<br />

1.2.3 <strong>HSE</strong> Culture<br />

Creating and sustaining an <strong>HSE</strong> culture that supports:<br />

The slogan “Safe Production” becoming a core value.<br />

The belief in <strong>PDO</strong>‟s desire to continually improve <strong>HSE</strong> performance.<br />

The motivation to improve individual, team, asset, and company level <strong>HSE</strong> performance.<br />

The acceptance <strong>of</strong> individual accountability and responsibility for <strong>HSE</strong> performance.<br />

Participation and involvement at all levels in the development, implementation, maintenance, and continual<br />

improvement <strong>of</strong> <strong>PDO</strong>‟s <strong>HSE</strong> Management System.<br />

Empowerment for all to intervene and stop any substandard and/or hazardous work activity without blame or redress.<br />

Empowerment for all to intervene, commend, and encourage safe work behaviour and activity.<br />

1.2.4 Informed Involvement<br />

Reviewing the progress both in the development and content <strong>of</strong> <strong>PDO</strong>‟s <strong>HSE</strong> Management System so as to ensure its ongoing<br />

suitability, adequacy, effectiveness, and continual improvement.<br />

Allocating appropriate resources and expertise to meet <strong>HSE</strong> goals, objectives, and targets (e.g., finance, manpower, time,<br />

technology, skills, and/or training).<br />

Undertaking relevant training and other <strong>HSE</strong> leadership competency development activities themselves.<br />

Being fully aware <strong>of</strong> <strong>PDO</strong>‟s high priority areas for improvements identified in the <strong>HSE</strong> Management System, particularly in<br />

relation to legal compliance, risk level, and stakeholder issues.<br />

Being fully aware <strong>of</strong> the status <strong>of</strong> follow up actions.<br />

<strong>PDO</strong>‟s commitment to <strong>HSE</strong> shall further be demonstrated and strengthened by:<br />

Achieving and maintaining external certification <strong>of</strong> the <strong>HSE</strong> Management System to international standards<br />

Communicating its <strong>HSE</strong> expectations to employees and contractors via various channels and best-practice activities.<br />

Developing annually <strong>HSE</strong> Plan(s) and by including <strong>HSE</strong> issues in strategic planning and business risk assessments.<br />

1.3 PROCEDURES<br />

The procedures specified in Section 1.3 for Leadership and Commitment at all levels shall be met as part <strong>of</strong> the job<br />

accountabilities and responsibilities defined for each individual within the Corporate Management Framework, Job Descriptions,<br />

etc.<br />

1.4 REFERENCES<br />

The following documents provide further / related information on Leadership and Commitment:<br />

<strong>PDO</strong> Policies PL-04 – Health, Safety, and Environmental Protection PL 04<br />

<strong>PDO</strong> <strong>Code</strong>s <strong>of</strong> <strong>Practice</strong> <strong>CP</strong>-107 – Corporate Management Framework <strong>CP</strong> 107<br />

<strong>PDO</strong> <strong>HSE</strong> Procedures No direct link exists and/or is required. --<br />

<strong>PDO</strong> <strong>HSE</strong> Specifications No direct link exists and/or is required. --<br />

<strong>PDO</strong> <strong>HSE</strong> Guidelines No direct link exists and/or is required. --<br />

Other <strong>PDO</strong> Documents<br />

Shell Group Documents<br />

Other Documents<br />

Statement <strong>of</strong> General Business Principles (SGBP)<br />

<strong>PDO</strong> <strong>Code</strong> <strong>of</strong> Conduct<br />

Shell HSSE & SP Control Framework, Version 2, (Shell Group Standards for<br />

Health, Security, Safety, the Environment & Social Performance)<br />

Occupational Health and Safety Assessment Series<br />

The Center for Chemical Process Safety (C<strong>CP</strong>S - www.aiche.org/ccps)<br />

January 2007<br />

April 2011<br />

December 2009<br />

OHSAS 18001:2007<br />

C<strong>CP</strong>S (2010)<br />

July 2011 Page 13

HEALTH, SAFETY AND ENVIRONMENT<br />

CODE OF PRACTICE (<strong>CP</strong>-<strong>122</strong>)<br />

<strong>PDO</strong> <strong>HSE</strong> Management System Manual<br />

2. POLICY AND STRATEGIC OBJECTIVES<br />

2.1 OVERVIEW<br />

It is <strong>PDO</strong>‟s policy to conduct its business properly with respect to <strong>HSE</strong> (within the scope <strong>of</strong> legal and other requirements), not to<br />

violate these requirements, abide by all legal decisions, and to maintain a positive and proactive team approach to <strong>HSE</strong> at all<br />

times.<br />

<strong>PDO</strong> has a set <strong>of</strong> 15 business policies including the <strong>HSE</strong> Policy (PL-04). The <strong>HSE</strong> policy is the highest level document in <strong>PDO</strong>‟s<br />

<strong>HSE</strong> MS and is aimed at achieving the ultimate goal <strong>of</strong> zero harm to people and the environment.<br />

It is endorsed by the MDC and approved by the Managing Director. Its content is consistent with the requirements <strong>of</strong> the <strong>PDO</strong><br />

Corporate Management Framework, ISO 14001 (for environmental management), OHSAS 18001 (for occupational health and<br />

safety management), and the Center for Chemical Process Safety / C<strong>CP</strong>S (for Process Safety). It also commits <strong>PDO</strong> to comply<br />

with all applicable Omani laws and regulations and continually strive to achieve improvement in <strong>HSE</strong> performance.<br />

<strong>PDO</strong>‟s overall business strategy is to integrate and balance economic, health, safety (occupational and process),<br />

environmental, and social requirements in all that we do, using risk-based approaches.<br />

To help focus our efforts at the strategy level, <strong>PDO</strong> has developed a Statement <strong>of</strong> General Business Principles (SGBP); also,<br />

various strategic objectives for <strong>HSE</strong> are also established, and these are reviewed and revised as required on an annual basis.<br />

2.2 REQUIREMENTS<br />

Senior Leadership at <strong>PDO</strong> shall define and document its<br />

<strong>HSE</strong> policy and strategic objectives and ensure that<br />

they:<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Are consistent with those <strong>of</strong> the Company‟s external<br />

stakeholders.<br />

Are relevant to the Company‟s activities, products,<br />

and/or services.<br />

Are consistent with and are <strong>of</strong> equal importance to<br />

<strong>PDO</strong>‟s other business policies and strategic<br />

objectives.<br />

Are publicly available.<br />

Commit the Company to meet or exceed all<br />

relevant regulatory and/or legislative requirements.<br />

Commit the Company to reduce their risks and<br />

hazards to health, safety, and the environment to<br />

levels which are “As Low as Reasonably<br />

Practicable” (ALARP).<br />

Provide a structured framework for achieving<br />

continual improvement in both <strong>HSE</strong> performance<br />

and the management system.<br />

2.2.1 <strong>HSE</strong> Policy<br />

<strong>PDO</strong>‟s <strong>HSE</strong> policy shall be produced in an easy to read format in both Arabic and English, and be approved and dated by <strong>PDO</strong>‟s<br />

Managing Director. To be effective, all employees and company contractors should be made aware <strong>of</strong> the <strong>HSE</strong> policy‟s<br />

existence. Its content, requirements, and intent should be formally distributed, communicated, and explained by all relevant <strong>PDO</strong><br />

Leadership.<br />

July 2011 Page 14

HEALTH, SAFETY AND ENVIRONMENT<br />

CODE OF PRACTICE (<strong>CP</strong>-<strong>122</strong>)<br />

<strong>PDO</strong> <strong>HSE</strong> Management System Manual<br />

2.2.2 <strong>HSE</strong> Strategic Objectives<br />

<strong>PDO</strong>‟s Statement <strong>of</strong> General Business Principles with respect to <strong>HSE</strong> and the management system shall be supported by goals,<br />

objectives, and targets at the corporate and asset levels, and are developed each year as part <strong>of</strong> <strong>PDO</strong>‟s strategic and business<br />

planning process. Refer to Chapter 5 <strong>of</strong> this Manual “Planning and Procedures” for more details about <strong>PDO</strong>‟s <strong>HSE</strong> planning<br />

process.<br />

Annual <strong>HSE</strong> plans and programs shall be implemented through People & Organisation, Business Processes, and Managing<br />

Assets. The business results <strong>of</strong> these shall be analyzed and reviewed against goals, objectives, and targets, and these results<br />

and feedback used to set future goals, objectives, and targets.<br />

2.3 PROCEDURES<br />

2.3.1 <strong>HSE</strong> Policy<br />

The process and requirements for managing the <strong>PDO</strong> <strong>HSE</strong> Policy is detailed in the flowchart below.<br />

2.3.2 Legal and Other Requirements<br />

In order to ensure that the <strong>HSE</strong> policy, and therefore the strategic objectives are in line with all legal and other requirements, the<br />

following process shall be followed.<br />

Head <strong>of</strong> Corporate Legal Department:<br />

<br />

Maintain a “legal register” <strong>of</strong> all current Royal Decrees (RDs), Ministerial Decisions (MDs), and supporting Ministerial<br />

documents relating to <strong>HSE</strong> management.<br />

Maintain a “register <strong>of</strong> other requirements” document relating to <strong>HSE</strong> management including ISO 14001, OHSAS 18001,<br />

C<strong>CP</strong>S, etc.<br />

<br />

<br />

<br />

Obtain and retain on file a current <strong>of</strong>ficial Arabic transcript <strong>of</strong> each document.<br />

Obtain and retain on file an English translation <strong>of</strong> each document.<br />

Identify and review proposed and actual changes in legal and other requirements, and update the Corporate <strong>HSE</strong> Manager<br />

<strong>of</strong> these changes in legal and other requirements.<br />

July 2011 Page 15

HEALTH, SAFETY AND ENVIRONMENT<br />

CODE OF PRACTICE (<strong>CP</strong>-<strong>122</strong>)<br />

<strong>PDO</strong> <strong>HSE</strong> Management System Manual<br />

Corporate <strong>HSE</strong> Manager:<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Review legal and other requirements, and incorporate these legal and other requirements into the development and<br />

subsequent review <strong>of</strong> <strong>PDO</strong>‟s <strong>HSE</strong> MS.<br />

Review all applications for <strong>HSE</strong> licenses, approvals, and/or permits. Where necessary, coordinate negotiating the terms<br />

and conditions with any relevant party(ies).<br />

Submit license, approvals, and/or permit applications to the Ministry <strong>of</strong> Environment and Climate Affairs (MECA).<br />

Coordinate <strong>PDO</strong>‟s participation and input to Omani regulatory authorities in drafting new <strong>HSE</strong> laws and changes to existing<br />

laws.<br />

Develop asset level business controls that incorporate <strong>PDO</strong>‟s <strong>HSE</strong> legal and other requirements.<br />

Develop appropriate business controls to (a) obtain all necessary <strong>HSE</strong> licenses, approvals, and/or permits. Ensure they are<br />

cross referenced to the appropriate legal requirement, and referred to in the „Legal Register,‟ if applicable; (b) meet the<br />

implementation and technical conditions <strong>of</strong> <strong>HSE</strong> licenses, approvals, and/or permits; and (c) ensure proactive and timely<br />

review and renewal <strong>of</strong> <strong>HSE</strong> licenses, approvals, and/or permits.<br />

Review and update business controls to incorporate changes in <strong>PDO</strong>‟s <strong>HSE</strong> legal and other requirements.<br />

Retain on file a current copy <strong>of</strong> all <strong>HSE</strong> licenses, approvals, and/or permits.<br />

2.3.3 <strong>HSE</strong> Strategic Goals, Objectives, and Targets<br />

<strong>PDO</strong> <strong>HSE</strong> strategic objectives and corporate goals and targets for <strong>HSE</strong> performance shall be developed by the Corporate <strong>HSE</strong><br />

Manager in line with the <strong>HSE</strong> policy statement and based on <strong>PDO</strong>‟s risk pr<strong>of</strong>ile. While developing these, all Directors shall be<br />

actively engaged. Once developed, these shall be forwarded to the MDC for review and endorsement.<br />

The MDC endorsed corporate goals, objectives, and targets shall be communicated to the various Directorates. Each<br />

Directorate shall then develop their own goals, objectives, and targets in line with the corporate goals, objectives, and targets,<br />

and based on their own risk pr<strong>of</strong>iles. During this process, all Asset Directors / discipline level leaders, and <strong>HSE</strong> Advisors shall be<br />

actively engaged. <strong>HSE</strong> strategic objectives as well as the corporate / directorate goals, objectives, and targets shall be reviewed<br />

and revised, where necessary, on an annual basis.<br />

The annual <strong>HSE</strong> goals, objectives, and targets are captured in the Annual Business Plans. The <strong>HSE</strong> strategic objectives and the<br />

corporate goals, objectives, and targets shall be distributed, communicated, and explained to all contractors. They shall also be<br />

distributed, communicated, and explained to other key external stakeholders.<br />

l<br />

July 2011 Page 16

HEALTH, SAFETY AND ENVIRONMENT<br />

CODE OF PRACTICE (<strong>CP</strong>-<strong>122</strong>)<br />

<strong>PDO</strong> <strong>HSE</strong> Management System Manual<br />

2.4 REFERENCES<br />

The following documents provide further / related information on Policy and Strategic Objectives:<br />

<strong>PDO</strong> Policies<br />

<strong>PDO</strong> <strong>Code</strong>s <strong>of</strong> <strong>Practice</strong><br />

PL-04 – Health, Safety, and Environmental Protection<br />

PL-10 – Security Policy and Emergency Response Policy<br />

<strong>CP</strong>-100 – Policy Approval<br />

<strong>CP</strong>-107 – Corporate Management Framework<br />

PL 04<br />

PL 10<br />

<strong>CP</strong> 100<br />

<strong>CP</strong> 107<br />

<strong>PDO</strong> <strong>HSE</strong> Procedures No direct link exists and/or is required. --<br />

<strong>PDO</strong> <strong>HSE</strong> Specifications No direct link exists and/or is required. --<br />

<strong>PDO</strong> <strong>HSE</strong> Guidelines No direct link exists and/or is required. --<br />

Other <strong>PDO</strong> Documents<br />

Statement <strong>of</strong> General Business Principles (SGBP)<br />

<strong>PDO</strong> <strong>Code</strong> <strong>of</strong> Conduct<br />

January 2007<br />

April 2011<br />

Shell Group Documents<br />

Other Documents<br />

Shell HSSE & SP Control Framework, Version 2, (Shell Group Standards<br />

for Health, Security, Safety, the Environment & Social Performance)<br />

Environmental Management Systems –Specification with Guidance for<br />

Use<br />

Occupational Health and Safety Assessment Series<br />

The Center for Chemical Process Safety (C<strong>CP</strong>S - www.aiche.org/ccps)<br />

December 2009<br />

ISO 14001:2004<br />

OHSAS 18001:2007<br />

C<strong>CP</strong>S (2010)<br />

July 2011 Page 17

HEALTH, SAFETY AND ENVIRONMENT<br />

CODE OF PRACTICE (<strong>CP</strong>-<strong>122</strong>)<br />

<strong>PDO</strong> <strong>HSE</strong> Management System Manual<br />

3. ORGANISATION, RESPONSIBILITIES, RESOURCES, STANDARDS, AND<br />

DOCUMENTS<br />

3.1 OVERVIEW<br />

All employees, individually and collectively, are responsible for <strong>HSE</strong> performance at <strong>PDO</strong>. To develop an effective <strong>HSE</strong> MS<br />

and make it work, line accountability and responsibility, informed involvement, and the active participation <strong>of</strong> all levels <strong>of</strong><br />

leadership, is required. This accountability, responsibility, informed involvement, and active participation are exercised in <strong>PDO</strong><br />

through:<br />

The organisation structure that defines <strong>HSE</strong> accountabilities and responsibilities for each employee.<br />

The resources (human, time, physical, and financial, for <strong>HSE</strong> development, implementation, and continual improvement)<br />

provided.<br />

Communicating <strong>HSE</strong> MS requirements and standards to all employees, suppliers, contractors, and sub-contractors, and<br />

other relevant stakeholders.<br />

Planning and scheduling the development, documentation, implementation, ongoing maintenance, and continual<br />

improvement <strong>of</strong> the <strong>HSE</strong> MS.<br />

Ensuring that <strong>PDO</strong> employees, suppliers, contractors, and sub-contractors are competent, and that training is provided as<br />

needed to fill any competency gaps employees, suppliers, contractors, sub-contractors, and/or other relevant stakeholders<br />

may have for <strong>HSE</strong> success.<br />

3.2 REQUIREMENTS<br />

<strong>PDO</strong>‟s organisational structures at the corporate level and at the directorate levels are available on <strong>PDO</strong>‟s intranet.<br />

3.2.1 <strong>HSE</strong> Organisation<br />

With regard to <strong>HSE</strong> management, the Managing Director<br />

along with the Directors shall have the overall<br />

accountability for <strong>HSE</strong> management in <strong>PDO</strong>. The<br />

responsibility for implementing <strong>HSE</strong> Management System<br />

expectations / requirements and monitoring <strong>HSE</strong><br />

performance shall lie with the Line Leaders.<br />

<strong>HSE</strong> Advisors and Team Leaders shall provide the<br />

necessary technical advice to Line Leaders on <strong>HSE</strong> issues.<br />

The Management Representative for the <strong>HSE</strong> function<br />

shall be the Corporate <strong>HSE</strong> Manager, who shall be<br />

responsible for developing and maintaining the <strong>HSE</strong><br />

Management System as well as for <strong>HSE</strong> compliance<br />

assurance. The Corporate <strong>HSE</strong> Functional Discipline<br />

Heads (CFDHs) shall provide the necessary technical<br />

support to the Corporate <strong>HSE</strong> Manager.<br />

3.2.2 <strong>HSE</strong> Standards<br />

In addition to Omani law, <strong>PDO</strong> bases its <strong>HSE</strong> MS on other external standards and requirements. In line with the <strong>HSE</strong> Policy (PL-<br />

04), which requires a "systematic approach to <strong>HSE</strong> management," <strong>PDO</strong>‟s <strong>HSE</strong> Management System shall comply and be<br />

certified to the requirements <strong>of</strong> ISO 14001.<br />

STANDARD<br />

PERFORMANCE<br />

STANDARD<br />

MANAGEMENT SYSTEM<br />

PERFORMANCE STANDARD<br />

A standard represents agreement on best practice for the technology or process concerned. For example, ISO<br />

14001 is an international standard that represents worldwide agreement on best practices for environmental<br />

management. This is NOT a (technical) performance standard.<br />

A performance standard typically imposes quantifiable limits and targets, such as "how much gas can be<br />

released into the air." Many <strong>of</strong> the Royal Decrees and Ministerial Decisions in Oman are Performance<br />

Standards. These are <strong>of</strong>ten referred to as technical standards.<br />

A management system performance standard is a statement detailing WHO, does WHAT, WHEN and/or HOW<br />

OFTEN. These standards define performance expectations or requirements <strong>of</strong> <strong>PDO</strong> leadership, employees,<br />

and/or suppliers, contractors, and sub-contractors.<br />

July 2011 Page 18

HEALTH, SAFETY AND ENVIRONMENT<br />

CODE OF PRACTICE (<strong>CP</strong>-<strong>122</strong>)<br />

<strong>PDO</strong> <strong>HSE</strong> Management System Manual<br />

In addition to the above standard, <strong>PDO</strong>‟s <strong>HSE</strong> Management System also addresses other external requirements. Therefore,<br />

<strong>PDO</strong>‟s <strong>HSE</strong> Management System:<br />

Is aligned to and incorporates where relevant the requirements <strong>of</strong> OHSAS 18001, since this is also closely related to the<br />

requirements <strong>of</strong> ISO 14001.<br />

Is aligned to and incorporates where relevant the requirements <strong>of</strong> The Center for Chemical Process Safety (20 C<strong>CP</strong>S<br />

Elements for Process Safety).<br />

Adopts the general structure <strong>of</strong> the Shell HSSE & SP Control Framework (December 2009).<br />

The role <strong>of</strong> <strong>PDO</strong>‟s CFDHs includes responsibilities to screen technical innovation and promote technical <strong>HSE</strong> and business<br />

standards. The Functional Disciplines, therefore, shall be responsible for monitoring the development <strong>of</strong> industry and other<br />

standards, and incorporating them as applicable into <strong>PDO</strong>‟s business and <strong>HSE</strong> controls, and associated documentation.<br />

3.2.3 <strong>HSE</strong> Committees and Meetings<br />

There is a cascading network <strong>of</strong> dedicated <strong>HSE</strong> management committees and meetings within <strong>PDO</strong> for reviewing <strong>HSE</strong><br />

management and <strong>HSE</strong> performance, and which also ensures that current <strong>HSE</strong> issues are identified and communicated to all<br />

levels <strong>of</strong> the organisation in a timely manner. The <strong>HSE</strong> committees and meetings shall interface with business management<br />

committees and meetings at the same level <strong>of</strong> the company, enabling key <strong>HSE</strong> issues to be included on the agenda <strong>of</strong> these<br />

meetings. The reporting relationships between business management committees and meetings, and dedicated <strong>HSE</strong><br />

committees and meetings are as shown in the following figure.<br />

July 2011 Page 19

HEALTH, SAFETY AND ENVIRONMENT<br />

CODE OF PRACTICE (<strong>CP</strong>-<strong>122</strong>)<br />

<strong>PDO</strong> <strong>HSE</strong> Management System Manual<br />

3.2.4 <strong>HSE</strong> Responsibilities<br />

In <strong>PDO</strong>, <strong>HSE</strong> management shall be a line<br />

leadership and employee responsibility,<br />

requiring the active participation <strong>of</strong> all levels <strong>of</strong><br />

leadership and supervision.<br />

The Corporate <strong>HSE</strong> Manager, <strong>HSE</strong> CFDHs<br />

and the Asset <strong>HSE</strong> Team Leaders and<br />

Advisors shall act in an advisory and/or<br />

support capacity to <strong>PDO</strong>‟s line leaders and<br />

employees.<br />

<strong>PDO</strong>‟s <strong>HSE</strong> Policy, Commitment, and<br />

Accountabilities booklet describes <strong>HSE</strong> roles,<br />

accountabilities, and responsibilities at each<br />

level <strong>of</strong> the organisation.<br />

3.2.5 Individual Responsibilities<br />

Individual responsibilities and accountabilities relating to <strong>HSE</strong> management shall be as defined in individual Job Descriptions, an<br />

individual‟s Personal Performance Contract (PPC), supplemented by the specific requirements defined in the various <strong>HSE</strong><br />

Procedures and Specifications, which are available in <strong>PDO</strong>‟s Electronic Document Management System (EDMS). However, the<br />

key responsibilities and accountabilities with regard to <strong>HSE</strong> are summarized below:<br />

MANAGING DIRECTOR<br />

The Managing Director shall have the ultimate accountability for the <strong>HSE</strong> function in <strong>PDO</strong>. He/She along with the other<br />

members <strong>of</strong> the MDC shall be accountable for the <strong>HSE</strong> policy, strategy, planning, providing the necessary resources, and<br />

management review <strong>of</strong> the <strong>HSE</strong> MS.<br />

DIRECTORS<br />

All directors shall be primarily responsible for reviewing and endorsing the <strong>HSE</strong> policy, strategy, planning, resource allocation,<br />

monitoring <strong>HSE</strong> MS performance, and conducting <strong>HSE</strong> MS management reviews. In addition, Functional Directors as the line<br />

leaders <strong>of</strong> their assets / disciplines shall be accountable for the implementation <strong>of</strong> the <strong>HSE</strong> MS in their areas <strong>of</strong> control.<br />

CORPORATE <strong>HSE</strong> MANAGER<br />

The Corporate <strong>HSE</strong> Manager, as the Management Representative, has overall accountability for coordinating the development,<br />

maintenance, and improvement <strong>of</strong> <strong>PDO</strong>‟s <strong>HSE</strong> MS. He/She shall be responsible for developing <strong>HSE</strong> systems, procedures,<br />

standards, as well as <strong>HSE</strong> goals, objectives, and targets on an annual basis, and providing <strong>HSE</strong> compliance assurance to the<br />

management. In addition, he/she shall be responsible for the following:<br />

Providing specialist <strong>HSE</strong> advice to other CFDHs and assets.<br />

Analyzing corporate <strong>HSE</strong> data.<br />

Screening and dissemination <strong>of</strong> technical innovations in <strong>HSE</strong>.<br />

Stimulating creativity with respect to managing <strong>HSE</strong>.<br />

Spreading lateral learning about <strong>HSE</strong> across Asset Teams.<br />

Developing and planning <strong>of</strong> <strong>HSE</strong> with CFDHs, <strong>HSE</strong> Team Leaders, and <strong>HSE</strong> Advisers.<br />

Promoting technical standards on <strong>HSE</strong>.<br />

Managing <strong>HSE</strong> knowledge within <strong>PDO</strong>.<br />

Managing and coordinating <strong>HSE</strong> Assurance activities within <strong>PDO</strong>.<br />

CORPORATE <strong>HSE</strong> FUNCTIONAL DISCIPLINE HEADS<br />

<strong>HSE</strong> CFDHs, each <strong>of</strong> whom is a Subject Matter Expert (SME) in one <strong>of</strong> the <strong>HSE</strong> disciplines shall provide technical assistance to<br />

the Corporate <strong>HSE</strong> Manager in all his/her responsibilities, including <strong>HSE</strong> compliance assurance.<br />

July 2011 Page 20

HEALTH, SAFETY AND ENVIRONMENT<br />

CODE OF PRACTICE (<strong>CP</strong>-<strong>122</strong>)<br />

<strong>PDO</strong> <strong>HSE</strong> Management System Manual<br />

<strong>HSE</strong> TEAM LEADERS AND <strong>HSE</strong> ADVISORS (ASSETS AND PROJECTS)<br />

<strong>HSE</strong> Team Leaders and <strong>HSE</strong> Advisors (Assets and Projects) are primarily responsible for compliance assurance at the asset /<br />

project level and providing the necessary technical advice and guidance to the Asset / Project / Contractor Managers as and<br />

when needed.<br />

LINE LEADERS (OPERATIONS, ENGINEERING, AND PROJECTS)<br />

Asset Directors / Project Managers shall be accountable for implementing <strong>PDO</strong>‟s <strong>HSE</strong> Policy and the <strong>HSE</strong> Management System<br />

within their assets or projects. They shall have the overall accountability for implementing the <strong>HSE</strong> MS requirements in their<br />

assets / projects / contracts as well as monitoring <strong>HSE</strong> performance.<br />

TEAM LEADERS, LINE SUPERVISORS, AND CONTRACT HOLDERS<br />

Team Leaders, Line Supervisors, and Contract Holders shall be primarily responsible for ensuring that activities are carried out in<br />

accordance with <strong>PDO</strong>‟s <strong>HSE</strong> Policy and other requirements <strong>of</strong> <strong>PDO</strong>‟s <strong>HSE</strong> Management System.<br />

EMPLOYEES, SUPPLIERS, CONTRACTORS, AND SUB-CONTRACTORS<br />

All <strong>PDO</strong> employees, suppliers, contractors, and sub-contractors shall be responsible and accountable for following the<br />

instructions <strong>of</strong> their line leader / supervisor, in accordance with <strong>PDO</strong>‟s <strong>HSE</strong> Policy and other requirements <strong>of</strong> <strong>PDO</strong>‟s <strong>HSE</strong><br />

Management System.<br />

3.2.6 Committee / Meeting Responsibilities<br />

The <strong>HSE</strong> roles, responsibilities, and accountabilities <strong>of</strong> <strong>PDO</strong>‟s business management committees and <strong>HSE</strong> committees and<br />

meetings shall be as detailed in their respective Terms <strong>of</strong> Reference (ToR).<br />

3.3 PROCEDURES<br />

3.3.1 Types <strong>of</strong> Resources<br />

Effective operation <strong>of</strong> <strong>PDO</strong>‟s <strong>HSE</strong> Management System requires sufficient allocation <strong>of</strong> human, time, physical, and financial<br />

resources. <strong>HSE</strong> resource requirements shall be considered during the <strong>HSE</strong> management planning process (see Process 5 <strong>of</strong><br />

this Manual "Planning and Procedures") and during the <strong>HSE</strong> management review process (see Process 8 <strong>of</strong> this Manual<br />

"Review").<br />

HUMAN RESOURCES<br />

Employees, contractors, sub-contractors, suppliers, and other<br />

relevant stakeholders. Effective <strong>HSE</strong> management relies on the<br />

competence (relevant education, training, and/or experience) <strong>of</strong><br />

these people, and ultimately proactive workforce involvement.<br />

FINANCIAL RESOURCES<br />

Allocation <strong>of</strong> necessary budget(s) for people, equipment, materials,<br />

and the environment, by balancing financial cost against the<br />

expected residual risk. This also relates to the „ALARP‟ concept<br />

described in Process 4: Hazards and Effects Management (HEMP).<br />

TIME RESOURCES<br />

Allocating sufficient time to perform a task or activity in the “right<br />

way” – the healthy way, the safe way, the environmentally friendly<br />

way, the quality way, and the productive way.<br />

PHYSICAL RESOURCES<br />

<strong>PDO</strong>‟s assets (e.g., buildings, equipment, materials, vehicles, tools,<br />

technology, etc.). Allocating physical resources requires<br />

consideration <strong>of</strong> the <strong>HSE</strong> risks that arise in all <strong>of</strong> <strong>PDO</strong>‟s activities,<br />

including the supply chain (i.e., purchasing and procurement<br />

activities).<br />

Sufficient resource allocation shall also be considered in managing change (MOC) and during assessments <strong>of</strong> risk controls as<br />