OneSteel Sustainability Report 2010 (PDF) - Arrium

OneSteel Sustainability Report 2010 (PDF) - Arrium

OneSteel Sustainability Report 2010 (PDF) - Arrium

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

24<br />

<strong>OneSteel</strong><br />

<strong>Sustainability</strong><br />

<strong>Report</strong> <strong>2010</strong><br />

Environment<br />

1 2 3 4 5 6 7<br />

8<br />

Greenhouse Emissions<br />

Our Approach<br />

<strong>OneSteel</strong> is committed to pursuing<br />

a high standard of environmental<br />

management throughout its<br />

operations, as outlined in our<br />

Environmental Policy, available<br />

online at www.onesteel.com. We<br />

5<br />

strive for continual improvement<br />

of environmental performance, the<br />

4<br />

efficient use of resources, and the<br />

minimisation or prevention of pollution.<br />

3<br />

<strong>OneSteel</strong> recognises that steelmaking<br />

has inherent resources requirements<br />

2<br />

and emissions intensity. The following<br />

section details our performance in<br />

1<br />

environmental areas as we seek to<br />

use energy, fresh water and other<br />

0<br />

resources more efficiently where<br />

5<br />

economically viable.<br />

We also seek to comply with applicable<br />

4<br />

environmental laws, regulations and<br />

mandatory standards. Where these do<br />

3<br />

not exist, we apply appropriate internal<br />

standards that reflect <strong>OneSteel</strong>’s<br />

2<br />

commitment to minimise adverse<br />

environmental impacts resulting from<br />

1<br />

its operations, products and services.<br />

Our Performance:<br />

Greenhouse Gas Emissions<br />

<strong>OneSteel</strong>’s energy and greenhouse<br />

0<br />

inventory is calculated for Australian<br />

sites that fall under <strong>OneSteel</strong>’s<br />

operational control. This captures<br />

the vast majority of <strong>OneSteel</strong>’s<br />

emissions with the non-Australian<br />

operations likely to represent less<br />

than one percent of <strong>OneSteel</strong>’s<br />

greenhouse inventory.<br />

<strong>OneSteel</strong>’s current energy and<br />

greenhouse inventory aligns with<br />

the accounting methodologies<br />

of the Australian National<br />

Greenhouse Emissions <strong>Report</strong>ing<br />

Scheme (NGERS).<br />

<strong>OneSteel</strong>’s greenhouse emissions for<br />

the <strong>2010</strong> financial year are shown<br />

to the right. Approximately 88% of<br />

<strong>OneSteel</strong>’s greenhouse gas emissions<br />

derive from the steelmaking and hot–<br />

roll/forging operations at Whyalla in<br />

South Australia, Sydney and Waratah<br />

in New South Wales and Laverton<br />

in Victoria.<br />

<strong>OneSteel</strong> updates its historical<br />

energy and greenhouse data in<br />

line with changes to governmental<br />

carbon accounting methodologies<br />

and conversion factors so that a<br />

common approach is presented in the<br />

underlying data as far as practicable.<br />

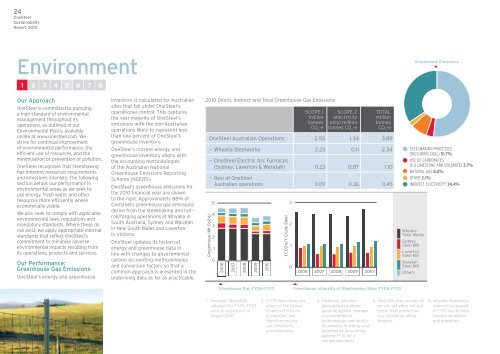

<strong>2010</strong> Direct, Indirect and Total Greenhouse Gas Emissions<br />

Greenhouse (Mt Co2-e)<br />

Scope 1<br />

million<br />

tonnes<br />

CO 2<br />

-e<br />

Scope 2<br />

(electricity<br />

only) million<br />

tonnes CO 2<br />

-e<br />

Total<br />

million<br />

tonnes<br />

CO 2<br />

-e<br />

<strong>OneSteel</strong> Australian Operations 2.55 1.34 3.89<br />

— Whyalla Steelworks 2.23 0.11 2.34<br />

— <strong>OneSteel</strong> Electric Arc Furnaces<br />

(Sydney, Laverton & Waratah) 0.23 0.87 1.10<br />

— Rest of <strong>OneSteel</strong><br />

Australian operations 0.09 0.36 0.45<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

2006<br />

2007<br />

2008<br />

2009<br />

<strong>2010</strong><br />

t CO2-e/ t Crude Steel<br />

3<br />

2<br />

1<br />

0<br />

2006 2007 2008 2009 <strong>2010</strong><br />

Steelmaking Processes<br />

• (including coal) 51.7%<br />

Use of Carbonates<br />

Natural Gas 8.0%<br />

Other 2.1%<br />

•<br />

(e.g limestone and dolomite) 3.7%<br />

Indirect Electricity 34.4%<br />

Whyalla<br />

Steel Works 1.5<br />

Sydney<br />

Steel Mill 1.0<br />

Laverton<br />

0.5<br />

Steel Mill<br />

Waratah<br />

0.0<br />

Steel Mill<br />

Others<br />

3.0<br />

2.5<br />

2.0<br />

Greenhouse Gas FY06-FY10<br />

Greenhouse Intensity of Steelmaking Sites FY06-FY10<br />

1. Smorgon Steel data<br />

obtained for FY06, FY07<br />

prior to acquisition in<br />

August 2007.<br />

2. FY09 data shows the<br />

effect of the Global<br />

Financial Crisis on<br />

production, and<br />

therefore energy<br />

use, emissions,<br />

and intensities.<br />

3. Historical data has<br />

been adjusted where<br />

possible against changes<br />

in governmental<br />

methodology and facility<br />

boundaries in energy and<br />

greenhouse accounting<br />

against FY10 for a<br />

comparable basis.<br />

4. Steel Mill sites include all<br />

on–site activities not just<br />

crude steel production<br />

(e.g. including rolling,<br />

forging).<br />

5. Whyalla Steelworks<br />

intensity increased<br />

in FY10 due to blast<br />

furnace problems<br />

and downtime.