“A Stitch in Time...”

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

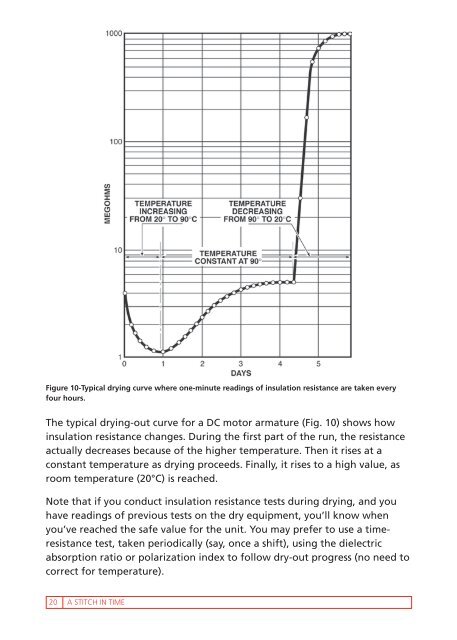

Figure 10-Typical dry<strong>in</strong>g curve where one-m<strong>in</strong>ute read<strong>in</strong>gs of <strong>in</strong>sulation resistance are taken every<br />

four hours.<br />

The typical dry<strong>in</strong>g-out curve for a DC motor armature (Fig. 10) shows how<br />

<strong>in</strong>sulation resistance changes. Dur<strong>in</strong>g the first part of the run, the resistance<br />

actually decreases because of the higher temperature. Then it rises at a<br />

constant temperature as dry<strong>in</strong>g proceeds. F<strong>in</strong>ally, it rises to a high value, as<br />

room temperature (20°C) is reached.<br />

Note that if you conduct <strong>in</strong>sulation resistance tests dur<strong>in</strong>g dry<strong>in</strong>g, and you<br />

have read<strong>in</strong>gs of previous tests on the dry equipment, you’ll know when<br />

you’ve reached the safe value for the unit. You may prefer to use a timeresistance<br />

test, taken periodically (say, once a shift), us<strong>in</strong>g the dielectric<br />

absorption ratio or polarization <strong>in</strong>dex to follow dry-out progress (no need to<br />

correct for temperature).<br />

20<br />

A STITCH IN TIME