SPRING 2011

Distributor's Link Magazine Spring Issue 2011 / VOL 34 / NO.2

Distributor's Link Magazine Spring Issue 2011 / VOL 34 / NO.2

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

82 THE DISTRIBUTOR’S LINK<br />

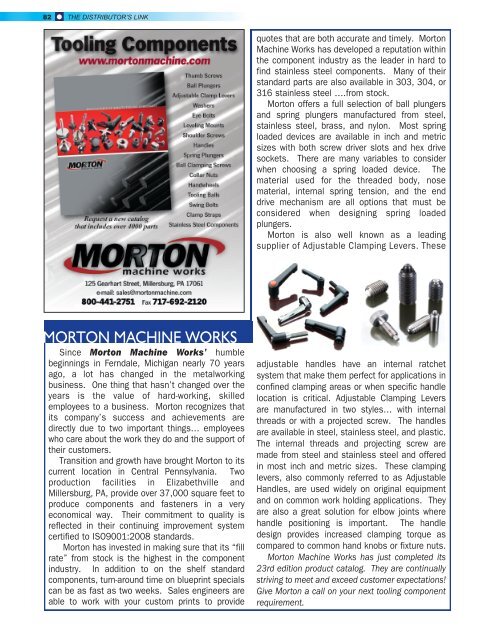

quotes that are both accurate and timely. Morton<br />

Machine Works has developed a reputation within<br />

the component industry as the leader in hard to<br />

find stainless steel components. Many of their<br />

standard parts are also available in 303, 304, or<br />

316 stainless steel ….from stock.<br />

Morton offers a full selection of ball plungers<br />

and spring plungers manufactured from steel,<br />

stainless steel, brass, and nylon. Most spring<br />

loaded devices are available in inch and metric<br />

sizes with both screw driver slots and hex drive<br />

sockets. There are many variables to consider<br />

when choosing a spring loaded device. The<br />

material used for the threaded body, nose<br />

material, internal spring tension, and the end<br />

drive mechanism are all options that must be<br />

considered when designing spring loaded<br />

plungers.<br />

Morton is also well known as a leading<br />

supplier of Adjustable Clamping Levers. These<br />

Since Morton Machine Works’ humble<br />

beginnings in Ferndale, Michigan nearly 70 years<br />

ago, a lot has changed in the metalworking<br />

business. One thing that hasn’t changed over the<br />

years is the value of hard-working, skilled<br />

employees to a business. Morton recognizes that<br />

its company’s success and achievements are<br />

directly due to two important things… employees<br />

who care about the work they do and the support of<br />

their customers.<br />

Transition and growth have brought Morton to its<br />

current location in Central Pennsylvania. Two<br />

production facilities in Elizabethville and<br />

Millersburg, PA, provide over 37,000 square feet to<br />

produce components and fasteners in a very<br />

economical way. Their commitment to quality is<br />

reflected in their continuing improvement system<br />

certified to ISO9001:2008 standards.<br />

Morton has invested in making sure that its “fill<br />

rate” from stock is the highest in the component<br />

industry. In addition to on the shelf standard<br />

components, turn-around time on blueprint specials<br />

can be as fast as two weeks. Sales engineers are<br />

able to work with your custom prints to provide<br />

adjustable handles have an internal ratchet<br />

system that make them perfect for applications in<br />

confined clamping areas or when specific handle<br />

location is critical. Adjustable Clamping Levers<br />

are manufactured in two styles… with internal<br />

threads or with a projected screw. The handles<br />

are available in steel, stainless steel, and plastic.<br />

The internal threads and projecting screw are<br />

made from steel and stainless steel and offered<br />

in most inch and metric sizes. These clamping<br />

levers, also commonly referred to as Adjustable<br />

Handles, are used widely on original equipment<br />

and on common work holding applications. They<br />

are also a great solution for elbow joints where<br />

handle positioning is important. The handle<br />

design provides increased clamping torque as<br />

compared to common hand knobs or fixture nuts.<br />

Morton Machine Works has just completed its<br />

23rd edition product catalog. They are continually<br />

striving to meet and exceed customer expectations!<br />

Give Morton a call on your next tooling component<br />

requirement.