Drucken plastics 01_04 _E_dp - BASF Plastics Portal

Drucken plastics 01_04 _E_dp - BASF Plastics Portal

Drucken plastics 01_04 _E_dp - BASF Plastics Portal

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Dear Readers,<br />

Soon we will once again see the ecstasy<br />

of victory and the agony of defeat. The<br />

TV will be on non-stop when the whistle<br />

is blown to mark the beginning of the<br />

European Soccer Championships in Portugal<br />

or when the Olympic torch burns<br />

brightly above Athens. In this issue of<br />

“<strong>plastics</strong>”, we would like to whet your<br />

appetite for these major events but in<br />

particular, we want to kindle your interest<br />

in being active. “<strong>plastics</strong>” had a look<br />

around the world of sports and discovered<br />

that <strong>plastics</strong> have not only replaced<br />

traditional materials, but have also paved<br />

the way for new and trendy types of<br />

sports to break through. This is where<br />

we find people like Titus Dittmann, who<br />

has become synonymous with skateboarding.<br />

Entrepreneur of the Year in<br />

20<strong>01</strong>, he gives us a glimpse backstage<br />

and makes one point very clear: <strong>plastics</strong><br />

get his world rolling. But we also have<br />

other topics in store to leave you clamoring<br />

for more. Such as the extrusion<br />

products <strong>BASF</strong> took over from<br />

Honeywell that are now part of a uniform<br />

global product portfolio.<br />

Enjoy your reading.<br />

The Editors<br />

<strong>plastics</strong> inside<br />

Title 4<br />

resistance in sportswear, abrasion resistance<br />

for wheels all the way to impact and<br />

scratch resistance for skis and snowboards.<br />

When it comes to function, <strong>plastics</strong> have<br />

long since replaced leather, rubber, textile<br />

and wood in sports gear.<br />

Shoes – a<br />

high-tech product<br />

Although doing sports does wonders for<br />

the body, the feet sometimes pay the price.<br />

This is where special <strong>plastics</strong> such as Elastollan<br />

® – a thermoplastic polyurethane (TPU)<br />

made by the <strong>BASF</strong> subsidiary Elastrogran –<br />

come to the rescue. This material can be<br />

found in soles and toe caps as well as in<br />

the reinforcing and damping elements of<br />

high-quality sports shoes. This TPU is more<br />

flexible, sturdy and durable than most other<br />

<strong>plastics</strong>. What<br />

ther-<br />

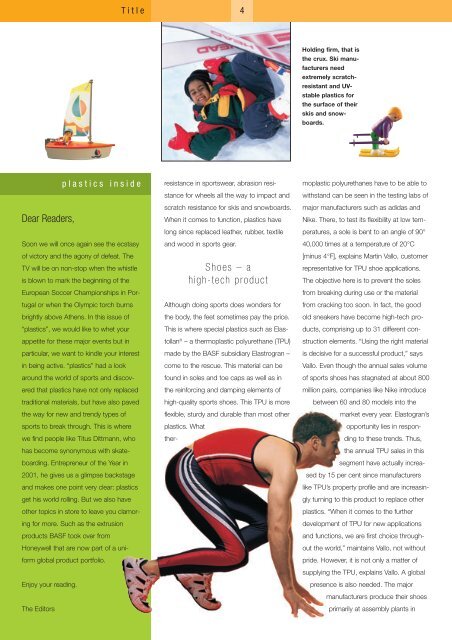

Holding firm, that is<br />

the crux. Ski manufacturers<br />

need<br />

extremely scratchresistant<br />

and UVstable<br />

<strong>plastics</strong> for<br />

the surface of their<br />

skis and snowboards.<br />

moplastic polyurethanes have to be able to<br />

withstand can be seen in the testing labs of<br />

major manufacturers such as adidas and<br />

Nike. There, to test its flexibility at low temperatures,<br />

a sole is bent to an angle of 90°<br />

40,000 times at a temperature of 20°C<br />

[minus 4°F], explains Martin Vallo, customer<br />

representative for TPU shoe applications.<br />

The objective here is to prevent the soles<br />

from breaking during use or the material<br />

from cracking too soon. In fact, the good<br />

old sneakers have become high-tech products,<br />

comprising up to 31 different construction<br />

elements. “Using the right material<br />

is decisive for a successful product,” says<br />

Vallo. Even though the annual sales volume<br />

of sports shoes has stagnated at about 800<br />

million pairs, companies like Nike introduce<br />

between 60 and 80 models into the<br />

market every year. Elastogran’s<br />

opportunity lies in responding<br />

to these trends. Thus,<br />

the annual TPU sales in this<br />

segment have actually increased<br />

by 15 per cent since manufacturers<br />

like TPU’s property profile and are increasingly<br />

turning to this product to replace other<br />

<strong>plastics</strong>. “When it comes to the further<br />

development of TPU for new applications<br />

and functions, we are first choice throughout<br />

the world,” maintains Vallo, not without<br />

pride. However, it is not only a matter of<br />

supplying the TPU, explains Vallo. A global<br />

presence is also needed. The major<br />

manufacturers produce their shoes<br />

primarily at assembly plants in