04. 01 Directory chapter 04 Connectors with press-in termination

04. 01 Directory chapter 04 Connectors with press-in termination

04. 01 Directory chapter 04 Connectors with press-in termination

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Press-<strong>in</strong> technology<br />

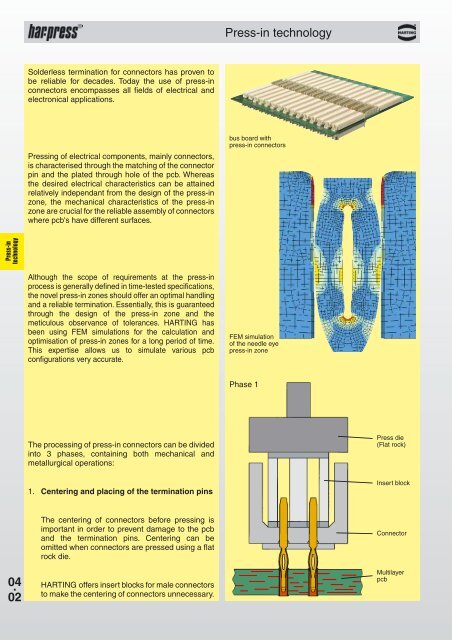

Solderless term<strong>in</strong>ation for connectors has proven to<br />

be reliable for decades. Today the use of <strong>press</strong>-<strong>in</strong><br />

connectors encompasses all fields of electrical and<br />

electronical applications.<br />

Press<strong>in</strong>g of electrical components, ma<strong>in</strong>ly connectors,<br />

is characterised through the match<strong>in</strong>g of the connector<br />

p<strong>in</strong> and the plated through hole of the pcb. Whereas<br />

the desired electrical characteristics can be atta<strong>in</strong>ed<br />

relatively <strong>in</strong>dependant from the design of the <strong>press</strong>-<strong>in</strong><br />

zone, the mechanical characteristics of the <strong>press</strong>-<strong>in</strong><br />

zone are crucial for the reliable assembly of connectors<br />

where pcb's have different surfaces.<br />

bus board <strong>with</strong><br />

<strong>press</strong>-<strong>in</strong> connectors<br />

Press-<strong>in</strong><br />

technology<br />

Although the scope of requirements at the <strong>press</strong>-<strong>in</strong><br />

process is generally def<strong>in</strong>ed <strong>in</strong> time-tested specifications,<br />

the novel <strong>press</strong>-<strong>in</strong> zones should offer an optimal handl<strong>in</strong>g<br />

and a reliable term<strong>in</strong>ation. Essentially, this is guaranteed<br />

through the design of the <strong>press</strong>-<strong>in</strong> zone and the<br />

meticulous observance of tolerances. HARTING has<br />

been us<strong>in</strong>g FEM simulations for the calculation and<br />

optimisation of <strong>press</strong>-<strong>in</strong> zones for a long period of time.<br />

This expertise allows us to simulate various pcb<br />

configurations very accurate.<br />

FEM simulation<br />

of the needle eye<br />

<strong>press</strong>-<strong>in</strong> zone<br />

Phase 1<br />

The process<strong>in</strong>g of <strong>press</strong>-<strong>in</strong> connectors can be divided<br />

<strong>in</strong>to 3 phases, conta<strong>in</strong><strong>in</strong>g both mechanical and<br />

metallurgical operations:<br />

Press die<br />

(Flat rock)<br />

1. Center<strong>in</strong>g and plac<strong>in</strong>g of the term<strong>in</strong>ation p<strong>in</strong>s<br />

Insert block<br />

<strong>04</strong> .<br />

02<br />

The center<strong>in</strong>g of connectors before <strong>press</strong><strong>in</strong>g is<br />

important <strong>in</strong> order to prevent damage to the pcb<br />

and the term<strong>in</strong>ation p<strong>in</strong>s. Center<strong>in</strong>g can be<br />

omitted when connectors are <strong>press</strong>ed us<strong>in</strong>g a flat<br />

rock die.<br />

HARTING offers <strong>in</strong>sert blocks for male connectors<br />

to make the center<strong>in</strong>g of connectors unnecessary.<br />

Connector<br />

Multilayer<br />

pcb