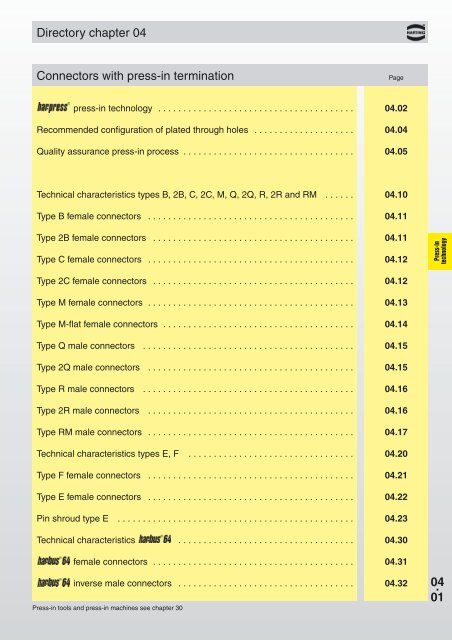

04. 01 Directory chapter 04 Connectors with press-in termination

04. 01 Directory chapter 04 Connectors with press-in termination

04. 01 Directory chapter 04 Connectors with press-in termination

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Directory</strong> <strong>chapter</strong> <strong>04</strong><br />

<strong>Connectors</strong> <strong>with</strong> <strong>press</strong>-<strong>in</strong> term<strong>in</strong>ation<br />

Page<br />

<strong>press</strong>-<strong>in</strong> technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong><strong>04</strong>.</strong>02<br />

Recommended configuration of plated through holes . . . . . . . . . . . . . . . . . . . . <strong><strong>04</strong>.</strong><strong>04</strong><br />

Quality assurance <strong>press</strong>-<strong>in</strong> process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong><strong>04</strong>.</strong>05<br />

Technical characteristics types B, 2B, C, 2C, M, Q, 2Q, R, 2R and RM . . . . . . <strong><strong>04</strong>.</strong>10<br />

Type B female connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong><strong>04</strong>.</strong>11<br />

Type 2B female connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong><strong>04</strong>.</strong>11<br />

Type C female connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong><strong>04</strong>.</strong>12<br />

Press-<strong>in</strong><br />

technology<br />

Type 2C female connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong><strong>04</strong>.</strong>12<br />

Type M female connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong><strong>04</strong>.</strong>13<br />

Type M-flat female connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong><strong>04</strong>.</strong>14<br />

Type Q male connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong><strong>04</strong>.</strong>15<br />

Type 2Q male connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong><strong>04</strong>.</strong>15<br />

Type R male connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong><strong>04</strong>.</strong>16<br />

Type 2R male connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong><strong>04</strong>.</strong>16<br />

Type RM male connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong><strong>04</strong>.</strong>17<br />

Technical characteristics types E, F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong><strong>04</strong>.</strong>20<br />

Type F female connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong><strong>04</strong>.</strong>21<br />

Type E female connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong><strong>04</strong>.</strong>22<br />

P<strong>in</strong> shroud type E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong><strong>04</strong>.</strong>23<br />

Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong><strong>04</strong>.</strong>30<br />

female connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong><strong>04</strong>.</strong>31<br />

<strong>in</strong>verse male connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong><strong>04</strong>.</strong>32<br />

Press-<strong>in</strong> tools and <strong>press</strong>-<strong>in</strong> mach<strong>in</strong>es see <strong>chapter</strong> 30<br />

<strong>04</strong> .<br />

<strong>01</strong>

Press-<strong>in</strong> technology<br />

Solderless term<strong>in</strong>ation for connectors has proven to<br />

be reliable for decades. Today the use of <strong>press</strong>-<strong>in</strong><br />

connectors encompasses all fields of electrical and<br />

electronical applications.<br />

Press<strong>in</strong>g of electrical components, ma<strong>in</strong>ly connectors,<br />

is characterised through the match<strong>in</strong>g of the connector<br />

p<strong>in</strong> and the plated through hole of the pcb. Whereas<br />

the desired electrical characteristics can be atta<strong>in</strong>ed<br />

relatively <strong>in</strong>dependant from the design of the <strong>press</strong>-<strong>in</strong><br />

zone, the mechanical characteristics of the <strong>press</strong>-<strong>in</strong><br />

zone are crucial for the reliable assembly of connectors<br />

where pcb's have different surfaces.<br />

bus board <strong>with</strong><br />

<strong>press</strong>-<strong>in</strong> connectors<br />

Press-<strong>in</strong><br />

technology<br />

Although the scope of requirements at the <strong>press</strong>-<strong>in</strong><br />

process is generally def<strong>in</strong>ed <strong>in</strong> time-tested specifications,<br />

the novel <strong>press</strong>-<strong>in</strong> zones should offer an optimal handl<strong>in</strong>g<br />

and a reliable term<strong>in</strong>ation. Essentially, this is guaranteed<br />

through the design of the <strong>press</strong>-<strong>in</strong> zone and the<br />

meticulous observance of tolerances. HARTING has<br />

been us<strong>in</strong>g FEM simulations for the calculation and<br />

optimisation of <strong>press</strong>-<strong>in</strong> zones for a long period of time.<br />

This expertise allows us to simulate various pcb<br />

configurations very accurate.<br />

FEM simulation<br />

of the needle eye<br />

<strong>press</strong>-<strong>in</strong> zone<br />

Phase 1<br />

The process<strong>in</strong>g of <strong>press</strong>-<strong>in</strong> connectors can be divided<br />

<strong>in</strong>to 3 phases, conta<strong>in</strong><strong>in</strong>g both mechanical and<br />

metallurgical operations:<br />

Press die<br />

(Flat rock)<br />

1. Center<strong>in</strong>g and plac<strong>in</strong>g of the term<strong>in</strong>ation p<strong>in</strong>s<br />

Insert block<br />

<strong>04</strong> .<br />

02<br />

The center<strong>in</strong>g of connectors before <strong>press</strong><strong>in</strong>g is<br />

important <strong>in</strong> order to prevent damage to the pcb<br />

and the term<strong>in</strong>ation p<strong>in</strong>s. Center<strong>in</strong>g can be<br />

omitted when connectors are <strong>press</strong>ed us<strong>in</strong>g a flat<br />

rock die.<br />

HARTING offers <strong>in</strong>sert blocks for male connectors<br />

to make the center<strong>in</strong>g of connectors unnecessary.<br />

Connector<br />

Multilayer<br />

pcb

Press-<strong>in</strong> technology<br />

2. Press<strong>in</strong>g <strong>in</strong> the p<strong>in</strong>s<br />

Phase 2<br />

In the <strong>press</strong>-<strong>in</strong> process the <strong>in</strong>sertion force is<br />

cont<strong>in</strong>uously transformed <strong>in</strong>to com<strong>press</strong>ion force.<br />

The result<strong>in</strong>g friction frees the contact<strong>in</strong>g bars of<br />

<strong>in</strong>sulat<strong>in</strong>g films. Superfluous plat<strong>in</strong>g (t<strong>in</strong>) is<br />

transferred <strong>with</strong><strong>in</strong> the plated through hole. A gastight<br />

connection of fresh non-oxidised metal<br />

surfaces is obta<strong>in</strong>ed.<br />

3. Obta<strong>in</strong><strong>in</strong>g the f<strong>in</strong>al position<br />

The <strong>press</strong>-<strong>in</strong> operation should be term<strong>in</strong>ated as<br />

soon as the connector obta<strong>in</strong>s its f<strong>in</strong>al position on<br />

the pcb to avoid unnecessary com<strong>press</strong>ive stress.<br />

The <strong>press</strong>-<strong>in</strong> mach<strong>in</strong>es of HARTING feature<br />

automatic term<strong>in</strong>ation of the <strong>press</strong>-<strong>in</strong> operation<br />

<strong>in</strong>dependant of pcb thickness and surface<br />

properties.<br />

Phase 3<br />

Press-<strong>in</strong><br />

technology<br />

The entire dynamic <strong>press</strong>-<strong>in</strong> process is characterised<br />

through changes of the <strong>press</strong>-<strong>in</strong> force that can be<br />

statistically evaluated. HARTING records the changes<br />

of force <strong>with</strong> the help of special software. This is an<br />

important step towards permanent process control and<br />

documented manufactur<strong>in</strong>g data.<br />

The -zone is based on the <strong>in</strong>dustry renowned<br />

needle eye technology. Its special design allows for<br />

compensation of tolerances of pcb surface properties<br />

(eg. superfluous t<strong>in</strong> plat<strong>in</strong>g). The excessive material is<br />

displaced <strong>with</strong><strong>in</strong> the plated through hole, whereby a<br />

gas-tight and corrosion resistant electrical connection<br />

is assured.<br />

Diameter<br />

plated through hole<br />

1.09 mm<br />

(max.)<br />

M 29:1<br />

II<br />

I<br />

M 58:1<br />

Diameter<br />

plated through hole<br />

0.99-1.00 mm<br />

(nom<strong>in</strong>al)<br />

M 29:1<br />

II<br />

I<br />

M 58:1<br />

Diameter<br />

plated through hole<br />

0.92-0.94 mm<br />

(m<strong>in</strong>.)<br />

M 29:1<br />

II<br />

I<br />

M 58:1<br />

II<br />

II<br />

II<br />

M 58:1<br />

M 58:1<br />

M 58:1<br />

I<br />

I<br />

I<br />

Cross section of a pcb 2.4 mm thick <strong>with</strong> various hole diameters<br />

<strong>04</strong> .<br />

03

Recommended configuration of plated through holes<br />

Due to the high deformation resistance and resilience of<br />

contacts, they can be easily and repeatedly<br />

removed <strong>in</strong> case of repairs <strong>with</strong>out impairment to their<br />

function<strong>in</strong>g.<br />

is extremely versatile and offers a reliable<br />

electrical contact, therefore it is especially well suited<br />

for applications <strong>with</strong> these surfaces.<br />

Please contact us for detailed test reports.<br />

chem. Sn<br />

Benefits of the <strong>press</strong>-<strong>in</strong> technology<br />

l Thermal shocks associated <strong>with</strong> the solder<strong>in</strong>g<br />

process and the risk of the board malfunction are<br />

avoided.<br />

pure Cu<br />

Pd<br />

Au<br />

Ag<br />

Press-<strong>in</strong><br />

technology<br />

l No need for the subsequent clean<strong>in</strong>g of the<br />

assembled pcb’s<br />

l Additional wrap connections are made possible by<br />

us<strong>in</strong>g connectors <strong>with</strong> long p<strong>in</strong>s<br />

l Unlimited and efficient process<strong>in</strong>g of partially goldplated<br />

p<strong>in</strong>s for rear I/O - manual solder<strong>in</strong>g is no<br />

longer necessary!<br />

Recommended configuration of plated through<br />

holes<br />

In addition to the hot-air-level (HAL) pcb surfaces are<br />

gett<strong>in</strong>g more important. Due to their different properties,<br />

such as mechanical strength and coefficient<br />

of friction we recommend the follow<strong>in</strong>g configuration<br />

of pcb through holes.<br />

Sketch:<br />

<strong>press</strong>-<strong>in</strong> zone<br />

<strong>in</strong> plated through hole<br />

T<strong>in</strong>-lead plated Hole 1.15 ±0.025 mm<br />

PCB Cu m<strong>in</strong>. 25 µm<br />

(HAL) Sn max. 15 µm<br />

acc. EN 60 352-5 Plated hole 0.94-1.09 mm<br />

Drilled hole<br />

Chemical Hole 1.15 ±0.025 mm<br />

t<strong>in</strong>-plated PCB Cu m<strong>in</strong>. 25 µm<br />

Sn m<strong>in</strong>. 0.8 µm<br />

Plated hole<br />

1.00-1.10 mm<br />

Au / Ni plated PCB Hole 1.15 ±0.025 mm<br />

Cu m<strong>in</strong>. 25 µm<br />

Ni 3-7 µm<br />

Au 0.05-0.12 µm<br />

Plated hole<br />

1.00-1.10 mm<br />

Silver plated PCB Hole 1.15 ±0.025 mm<br />

Cu m<strong>in</strong>. 25 µm<br />

Ag 0.1-0.3 µm<br />

Plated hole<br />

1.00-1.10 mm<br />

Cu<br />

<strong>04</strong> .<br />

<strong>04</strong><br />

OSP Hole 1.15 ±0.025 mm<br />

copper plated PCB Cu m<strong>in</strong>. 25 µm<br />

Plated hole<br />

1.00-1.10 mm<br />

PCB board thickness: ≥ 1,6 mm<br />

pcb holes<br />

for <strong>press</strong>-<strong>in</strong><br />

process <strong>in</strong> acc.<br />

to EN 60 352-5<br />

Sn<br />

Plated through hole

Quality assurance <strong>press</strong>-<strong>in</strong> process<br />

Quality control of the <strong>press</strong>-<strong>in</strong> term<strong>in</strong>ation<br />

The <strong>press</strong>-<strong>in</strong> force correlates <strong>with</strong> the diameter of the<br />

plated through hole and <strong>with</strong> the friction coefficient of<br />

the surface; therefore it can be used for a cont<strong>in</strong>uous<br />

monitor<strong>in</strong>g of the process.<br />

The retention force, as an <strong>in</strong>direct measure of the<br />

normal force, serves to qualify the process or random<br />

tests<br />

Press-<strong>in</strong> force / retemtion force per p<strong>in</strong> (<strong>in</strong> N)<br />

pcb thickness: 1.6 mm to 3.2 mm<br />

Plat<strong>in</strong>g of the <strong>press</strong>-<strong>in</strong> zone: Sn<br />

Plat<strong>in</strong>g of the hole:<br />

Sn<br />

m<strong>in</strong>./max. retention force<br />

m<strong>in</strong>./max. <strong>press</strong>-<strong>in</strong> force<br />

Press-<strong>in</strong><br />

technology<br />

Hole diameter (mm)<br />

Typical <strong>press</strong>-<strong>in</strong> and retention forces for the har·<strong>press</strong><br />

The automatic <strong>press</strong>-<strong>in</strong> mach<strong>in</strong>es of HARTING feature<br />

a graphical user <strong>in</strong>terface for monitor<strong>in</strong>g the process<br />

and the quality of the <strong>press</strong>-<strong>in</strong> term<strong>in</strong>ation (see <strong>chapter</strong><br />

30).<br />

HARTING assists you <strong>with</strong> the most advanced quality<br />

assurance methods beyond the usual scope.<br />

X-ray photo of a <strong>press</strong>ed-<strong>in</strong> connector<br />

<strong>04</strong> .<br />

05

Technical characteristics<br />

Types<br />

B, 2B, C, 2C, M, Q, 2Q, R, 2R and RM<br />

Press-<strong>in</strong><br />

technology<br />

Number of contacts 32-96<br />

Contact spac<strong>in</strong>g (mm) 2.54<br />

Work<strong>in</strong>g current<br />

2 A max.<br />

see current carry<strong>in</strong>g capacity chart<br />

Clearance<br />

≥ 1.2 mm<br />

Creepage<br />

≥ 1.2 mm<br />

Work<strong>in</strong>g voltage<br />

The work<strong>in</strong>g voltage also depends accord<strong>in</strong>g to the safety<br />

on the clearance and creepage regulations of the equipment<br />

dimensions of the pcb itself and Explanations see <strong>chapter</strong> 00<br />

the associated wir<strong>in</strong>g<br />

Test voltage U r.m.s.<br />

1 kV<br />

Contact resistance<br />

≤ 15 mΩ<br />

Insulation resistance<br />

≥ 10 12 Ω<br />

Temperature range – 40 °C … + 105 °C<br />

The upper temperature is<br />

limited by the property of the<br />

pcb material<br />

Current carry<strong>in</strong>g capacity<br />

The current carry<strong>in</strong>g capacity is limited by maximum temperature of<br />

materials for <strong>in</strong>serts and contacts <strong>in</strong>clud<strong>in</strong>g term<strong>in</strong>als. The current<br />

capacity curve is valid for cont<strong>in</strong>uous, non <strong>in</strong>terrupted current loaded<br />

contacts of connectors when simultaneous power on all contacts is<br />

given, <strong>with</strong>out exceed<strong>in</strong>g the maximum temperature.<br />

Control and test procedures accord<strong>in</strong>g to DIN IEC 60 512<br />

Work<strong>in</strong>g current<br />

Ambient temperature<br />

Electrical term<strong>in</strong>ation<br />

Male and female connectors<br />

Diameter of pcb plated through holes<br />

pcb thickness<br />

Recommended pcb holes for<br />

<strong>press</strong>-<strong>in</strong> process <strong>in</strong> acc. to EN 60 352-5 2)<br />

Compliant <strong>press</strong>-<strong>in</strong><br />

term<strong>in</strong>ations<br />

0.94-1.09 mm<br />

≥ 1.6 mm<br />

Insertion and <strong>with</strong>drawal force<br />

32pol. ≤ 30 N<br />

48pol. ≤ 45 N<br />

64pol. ≤ 60 N<br />

96pol. ≤ 90 N<br />

Materials<br />

Mould<strong>in</strong>gs<br />

Contacts<br />

Contact surface<br />

Contact zone<br />

Press-<strong>in</strong> zone<br />

Wrap zone<br />

<strong>with</strong> selectively gold plated<br />

wrap posts<br />

Thermoplastic res<strong>in</strong>,<br />

glass-fibre filled, UL 94-V0<br />

Copper alloy<br />

plated accord<strong>in</strong>g to<br />

performance level 1)<br />

t<strong>in</strong>ned<br />

t<strong>in</strong>ned<br />

wrap zone: t<strong>in</strong>ned<br />

<strong>in</strong>terface zone: gold plated<br />

accord<strong>in</strong>g to<br />

performance level 3<br />

<strong>04</strong> .<br />

10<br />

1)<br />

Explanation of performance levels see <strong>chapter</strong> 00<br />

2)<br />

for details see page <strong><strong>04</strong>.</strong><strong>04</strong><br />

Mat<strong>in</strong>g conditions see <strong>chapter</strong> 00<br />

Tool<strong>in</strong>g see <strong>chapter</strong> 30

DIN 41 612 · Types B and 2B<br />

Number of contacts<br />

64, 32<br />

Female connectors<br />

Number Contact<br />

Identification of contacts arrangement<br />

Female connector<br />

<strong>with</strong> <strong>press</strong>-<strong>in</strong> term<strong>in</strong>ations<br />

Part No. Performance levels accord<strong>in</strong>g to DIN 41 612. Explanation <strong>chapter</strong> 00<br />

3 2 1<br />

5.3 mm<br />

Type B<br />

64 Performance level 3 09 02 264 6850<br />

on request<br />

Performance level 1<br />

on request<br />

Type 2B<br />

32 09 22 232 6850<br />

Press-<strong>in</strong><br />

technology<br />

Dimensions<br />

row<br />

position<br />

b c d e<br />

Type B 31 x 2.54 (= 78.74) 90 ± 0.1 85.0 – 0.2 94.9 ± 0.1<br />

Type 2B 15 x 2.54 (= 38.1 ) 50 ± 0.1 44.4 – 0.2 54.9 ± 0.1<br />

Board drill<strong>in</strong>gs<br />

Mount<strong>in</strong>g side<br />

all holes<br />

X<br />

position<br />

row<br />

Other contact arrangements on request<br />

1)<br />

refer to recommended configuration of pcb holes, see page <strong><strong>04</strong>.</strong><strong>04</strong><br />

Dimensions <strong>in</strong> mm<br />

<strong>04</strong> .<br />

11

DIN 41 612 · Types C and 2C<br />

Number of contacts<br />

96, 64,<br />

48, 32<br />

Female connectors<br />

Identification<br />

Female connector<br />

Type C<br />

<strong>with</strong> <strong>press</strong>-<strong>in</strong> term<strong>in</strong>ations<br />

4.5 mm<br />

Number Contact<br />

of contacts arrangement<br />

Part No. Performance levels accord<strong>in</strong>g to DIN 41 612. Explanation <strong>chapter</strong> 00<br />

3 2 1<br />

96 09 03 296 7850 09 03 296 6850 09 03 296 2850<br />

64 09 03 264 7850 09 03 264 6850 09 03 264 2850<br />

32 09 03 232 7850 09 03 232 6850 09 03 232 2850<br />

Press-<strong>in</strong><br />

technology<br />

13.2 mm<br />

96<br />

64<br />

09 03 296 6851<br />

l09 03 296 6861 l<br />

09 03 264 6851<br />

l09 03 264 6861 l<br />

17 mm<br />

96<br />

09 03 296 6852<br />

l09 03 296 6862 l<br />

Female connector<br />

Type 2C<br />

<strong>with</strong> <strong>press</strong>-<strong>in</strong> term<strong>in</strong>ations<br />

4.5 mm<br />

48 09 23 248 6850<br />

Dimensions<br />

row<br />

position<br />

a b c d e f g<br />

Type C 4.5 31 90 85.0 94.9 0.3 0.75<br />

Type C 13.2 31 90 85.0 94.9 0.6 0.60<br />

Type C 17.0 31 90 85.0 94.9 0.6 0.60<br />

Type 2C 4.5 15 50 44.4 54.9 0.3 0.75<br />

Board drill<strong>in</strong>gs<br />

Mount<strong>in</strong>g side<br />

all holes<br />

row<br />

<strong>04</strong> .<br />

12<br />

l<br />

Wrap posts for <strong>in</strong>terfac<strong>in</strong>g selectively gold plated (performance level 3)<br />

Other contact arrangements on request<br />

1)<br />

refer to recommended configuration of pcb holes, see page <strong><strong>04</strong>.</strong><strong>04</strong><br />

position<br />

Dimensions <strong>in</strong> mm

DIN 41 612 · Type M<br />

Number of contacts<br />

78+2, 60+4<br />

42+6, 24+8<br />

Female connectors<br />

Number Contact<br />

Identification of contacts arrangement<br />

Female connector<br />

<strong>with</strong> <strong>press</strong>-<strong>in</strong> term<strong>in</strong>ations<br />

Part No. Performance levels accord<strong>in</strong>g to DIN 41 612. Explanation <strong>chapter</strong> 00<br />

3 2 1<br />

78 + 2 09 03 278 6850<br />

4.5 mm<br />

60 + 4 09 03 260 6850<br />

Performance level 3<br />

on request<br />

42 + 6 09 03 242 6850<br />

Performance level 1<br />

on request<br />

Dimensions<br />

24 + 8 09 03 224 6850<br />

Press-<strong>in</strong><br />

technology<br />

row<br />

position<br />

Panel cut out<br />

Order high current, high voltage, coaxial and<br />

fibre optic contacts separately, see <strong>chapter</strong> <strong>01</strong><br />

Contact arrangement<br />

view from term<strong>in</strong>ation side<br />

Board drill<strong>in</strong>gs<br />

Mount<strong>in</strong>g side<br />

all holes<br />

position<br />

row<br />

Other contact arrangements on request<br />

1)<br />

refer to recommended configuration of pcb holes, see page <strong><strong>04</strong>.</strong><strong>04</strong><br />

Type<br />

c<br />

78 + 2 25 x 2.54 = 63.50<br />

60 + 4 19 x 2.54 = 48.26<br />

42 + 6 13 x 2.54 = 33.02<br />

24 + 8 7 x 2.54 = 17.78<br />

Dimensions<br />

<strong>in</strong> mm<br />

<strong>04</strong> .<br />

13

DIN 41 612 · complementary type M-flat<br />

Number of contacts<br />

78+2, 60+4<br />

42+6, 24+8<br />

Female connectors<br />

Number Contact<br />

Identification of contacts arrangement<br />

Female connector<br />

<strong>with</strong> <strong>press</strong>-<strong>in</strong> term<strong>in</strong>ations<br />

Part No. Performance levels accord<strong>in</strong>g to DIN 41 612. Explanation <strong>chapter</strong> 00<br />

3 2 1<br />

78 + 2 09 03 278 6830<br />

4.5 mm<br />

60 + 4<br />

Performance level 3<br />

09 03 260 6830<br />

on request<br />

42 + 6 09 03 242 6830<br />

Performance level 1<br />

on request<br />

Press-<strong>in</strong><br />

technology<br />

High current female contact<br />

<strong>with</strong> <strong>press</strong>-<strong>in</strong> term<strong>in</strong>ation<br />

24 + 8 09 03 224 6830<br />

40 A<br />

09 03 000 6250<br />

Dimensions<br />

row<br />

position<br />

Order high current, high voltage, coaxial and<br />

fibre optic contacts separately, see <strong>chapter</strong> <strong>01</strong><br />

Panel cut out<br />

Contact arrangement<br />

view from term<strong>in</strong>ation side<br />

all holes<br />

Board drill<strong>in</strong>gs<br />

Mount<strong>in</strong>g side<br />

position<br />

<strong>04</strong> .<br />

14<br />

Other contact arrangements on request<br />

1)<br />

refer to recommended configuration of pcb holes, see page <strong><strong>04</strong>.</strong><strong>04</strong><br />

row<br />

Type<br />

c<br />

78 + 2 25 x 2.54 = 63.50<br />

60 + 4 19 x 2.54 = 48.26<br />

42 + 6 13 x 2.54 = 33.02<br />

24 + 8 7 x 2.54 = 17.78<br />

Dimensions<br />

<strong>in</strong> mm

DIN 41 612 · Type Q<br />

DIN 41 612 · complementary type 2Q<br />

Number of contacts<br />

64, 32<br />

Male connectors<br />

Identification<br />

Male connector<br />

Type Q<br />

<strong>with</strong> <strong>press</strong>-<strong>in</strong> term<strong>in</strong>ations<br />

Number Contact<br />

of contacts arrangement<br />

Part No. Performance levels accord<strong>in</strong>g to DIN 41 612. Explanation <strong>chapter</strong> 00<br />

3 2 1<br />

5.0 mm<br />

64 09 72 164 79<strong>04</strong> 09 72 164 69<strong>04</strong><br />

62 + 2 s 09 72 164 7954 09 72 164 6954<br />

13 mm<br />

Male connector<br />

Type 2Q<br />

<strong>with</strong> <strong>press</strong>-<strong>in</strong> term<strong>in</strong>ations<br />

64<br />

09 72 164 7985 09 72 164 6985<br />

l09 72 164 7974 l l 09 72 164 6974 l<br />

62 + 2 s 09 72 164 7995 09 72 164 6995<br />

performance level 1<br />

or special<br />

gold plat<strong>in</strong>g<br />

on request<br />

Press-<strong>in</strong><br />

technology<br />

5.0 mm<br />

32 09 27 132 79<strong>04</strong> 09 27 132 69<strong>04</strong><br />

30 + 2 s 09 27 132 7954 09 27 132 6954<br />

13 mm<br />

32 09 27 132 7985 09 27 132 6985<br />

30 + 2 s 09 27 132 7995 09 27 132 6995<br />

Dimensions<br />

Type Q<br />

Type 2Q<br />

row<br />

a<br />

5<br />

13<br />

row<br />

a<br />

5<br />

13<br />

position<br />

position<br />

Board drill<strong>in</strong>gs<br />

Mount<strong>in</strong>g side<br />

all holes<br />

position<br />

all holes<br />

position<br />

row<br />

row<br />

s<br />

Male connectors <strong>with</strong> 2 lead<strong>in</strong>g contacts (0.8 mm) pos. a1 and a32/a16<br />

l<br />

Wrap posts for <strong>in</strong>terfac<strong>in</strong>g selectively gold plated (performance level 3)<br />

1)<br />

refer to recommended configuration of pcb holes, see page <strong><strong>04</strong>.</strong><strong>04</strong><br />

Dimensions<br />

<strong>in</strong> mm<br />

Other contact arrangements as<br />

well <strong>with</strong> lagg<strong>in</strong>g p<strong>in</strong>s on request<br />

<strong>04</strong> .<br />

15

DIN 41 612 · Type R<br />

DIN 41 612 · complementary type 2R<br />

Number of contacts<br />

96, 64,<br />

48, 32<br />

Male connectors<br />

Identification<br />

Male connector<br />

Type R<br />

<strong>with</strong> <strong>press</strong>-<strong>in</strong> term<strong>in</strong>ations<br />

Number Contact<br />

of contacts arrangement<br />

Part No. Performance levels accord<strong>in</strong>g to DIN 41 612. Explanation <strong>chapter</strong> 00<br />

3 2 1<br />

5.0 mm<br />

96 09 73 196 79<strong>04</strong> 09 73 196 69<strong>04</strong><br />

94 + 2 s 09 73 196 7954 09 73 196 6954<br />

64 09 73 164 79<strong>04</strong> 09 73 164 69<strong>04</strong><br />

Press-<strong>in</strong><br />

technology<br />

13 mm<br />

96<br />

09 73 196 7985 09 73 196 6985<br />

l09 73 196 7974 l l 09 73 196 6974 l<br />

94 + 2 s 09 73 196 7995 09 73 196 6995<br />

performance level 1<br />

Male connector<br />

Type 2R<br />

<strong>with</strong> <strong>press</strong>-<strong>in</strong> term<strong>in</strong>ations<br />

64<br />

09 73 164 7985 09 73 164 6985<br />

l09 73 164 7974 l l 09 73 164 6974 l<br />

or special<br />

gold plat<strong>in</strong>g<br />

on request<br />

5.0 mm<br />

48 09 28 148 79<strong>04</strong> 09 28 148 69<strong>04</strong><br />

46 + 2 s 09 28 148 7954 09 28 148 6954<br />

32 09 28 132 79<strong>04</strong> 09 28 132 69<strong>04</strong><br />

13 mm<br />

48 09 28 148 7985 09 28 148 6985<br />

46 + 2 s 09 28 148 7995 09 28 148 6995<br />

Dimensions<br />

32 09 28 132 7985 09 28 132 6985<br />

Type R A-B<br />

Type 2R<br />

A-B<br />

row a<br />

5<br />

13<br />

position<br />

row<br />

position<br />

a<br />

5<br />

13<br />

Board drill<strong>in</strong>gs<br />

Mount<strong>in</strong>g side<br />

position<br />

all holes<br />

position<br />

all holes<br />

<strong>04</strong> .<br />

16<br />

row<br />

s<br />

Male connectors <strong>with</strong> 2 lead<strong>in</strong>g contacts (0.8 mm) pos. a1 and a32/a16<br />

l<br />

Wrap posts for <strong>in</strong>terfac<strong>in</strong>g selectively gold plated (performance level 3)<br />

1)<br />

refer to recommended configuration of pcb holes, see page <strong><strong>04</strong>.</strong><strong>04</strong><br />

row<br />

Dimensions <strong>in</strong> mm<br />

Other contact arrangements also<br />

<strong>with</strong> lagg<strong>in</strong>g p<strong>in</strong>s on request

DIN 41 612 · complementary type RM<br />

Number of contacts<br />

96, 64<br />

Male connectors<br />

Identification<br />

Male connector<br />

<strong>with</strong> <strong>press</strong>-<strong>in</strong> term<strong>in</strong>ations<br />

Number Contact<br />

of contacts arrangement<br />

Part No. Performance levels accord<strong>in</strong>g to DIN 41 612. Explanation <strong>chapter</strong> 00<br />

3 2 1<br />

5.0 mm<br />

13 mm<br />

96 performance level 3 performance level 2 09 79 196 2950<br />

or special<br />

or special<br />

64<br />

gold plat<strong>in</strong>g<br />

gold plat<strong>in</strong>g<br />

09 79 164 2950<br />

on request<br />

on request<br />

96 * 09 79 196 2961*<br />

Press-<strong>in</strong><br />

technology<br />

Dimensions<br />

A-B<br />

a<br />

5<br />

13<br />

row<br />

position<br />

Board drill<strong>in</strong>gs<br />

Mount<strong>in</strong>g side<br />

position<br />

all holes<br />

row<br />

* Wrap posts for <strong>in</strong>terfac<strong>in</strong>g selectively gold plated (performance level 2)<br />

1)<br />

refer to recommended configuration of pcb holes, see page <strong><strong>04</strong>.</strong><strong>04</strong><br />

Dimensions <strong>in</strong> mm<br />

Other contact arrangements on request<br />

<strong>04</strong> .<br />

17

Technical characteristics<br />

Types E and F<br />

Press-<strong>in</strong><br />

technology<br />

Number of contacts 32, 48<br />

Contact spac<strong>in</strong>g (mm) 5.08<br />

Work<strong>in</strong>g current<br />

see current carry<strong>in</strong>g capacity chart<br />

Clearance<br />

Creepage<br />

6 A max. for un<strong>press</strong>ed<br />

connectors*<br />

≥ 1.6 mm<br />

≥ 3.0 mm<br />

Work<strong>in</strong>g voltage<br />

The work<strong>in</strong>g voltage also depends accord<strong>in</strong>g to the safety<br />

on the clearance and creepage regulations of the equipment<br />

dimensions of the pcb itself and Explanations see <strong>chapter</strong> 00<br />

the associated wir<strong>in</strong>g<br />

Test voltage U r.m.s.<br />

1.55 kV<br />

Contact resistance<br />

≤ 15 mΩ<br />

Insulation resistance<br />

≥ 10 12 Ω<br />

Temperature range – 40 °C … + 105 °C<br />

The upper temperature is<br />

limited by the property of the<br />

pcb material<br />

Current carry<strong>in</strong>g capacity<br />

The current carry<strong>in</strong>g capacity is limited by maximum temperature of<br />

materials for <strong>in</strong>serts and contacts <strong>in</strong>clud<strong>in</strong>g term<strong>in</strong>als. The current<br />

capacity curve is valid for cont<strong>in</strong>uous, non <strong>in</strong>terrupted current loaded<br />

contacts of connectors when simultaneous power on all contacts is<br />

given, <strong>with</strong>out exceed<strong>in</strong>g the maximum temperature.<br />

Control and test procedures accord<strong>in</strong>g to DIN IEC 60 512<br />

Work<strong>in</strong>g current<br />

Ambient temperature<br />

Electrical term<strong>in</strong>ation<br />

Female connectors<br />

Diameter of pcb plated through holes<br />

pcb thickness<br />

Recommended pcb holes for<br />

<strong>press</strong>-<strong>in</strong> process <strong>in</strong> acc. EN 60 352-5 1)<br />

Compliant <strong>press</strong>-<strong>in</strong><br />

term<strong>in</strong>ations<br />

0.94-1.09 mm<br />

≥ 1.6 mm<br />

Insertion and <strong>with</strong>drawal force<br />

32pol. ≤ 50 N<br />

48pol. ≤ 75 N<br />

Materials<br />

Mould<strong>in</strong>gs<br />

Contacts<br />

Contact surface<br />

Contact zone<br />

Press-<strong>in</strong> zone<br />

Wrap zone<br />

<strong>with</strong> selectively gold plated<br />

wrap posts<br />

Thermoplastic res<strong>in</strong>,<br />

glass-fibre filled, UL 94-V0<br />

Copper alloy<br />

plated accord<strong>in</strong>g to<br />

performance level 2)<br />

t<strong>in</strong>ned<br />

t<strong>in</strong>ned<br />

wrap zone: t<strong>in</strong>ned<br />

<strong>in</strong>terface zone: gold plated<br />

accord<strong>in</strong>g to<br />

performance level 3<br />

<strong>04</strong> .<br />

20<br />

1)<br />

Details see page <strong><strong>04</strong>.</strong><strong>04</strong><br />

2)<br />

Explanation of performance levels see <strong>chapter</strong> 00<br />

Mat<strong>in</strong>g conditions see <strong>chapter</strong> 00<br />

* Is limited by the property of the pbc material to 4 A max. if the connector is <strong>press</strong>ed-<strong>in</strong>.<br />

Tool<strong>in</strong>g see <strong>chapter</strong> 30

DIN 41 612 · Type F<br />

Number of contacts<br />

48, 32<br />

Female connectors<br />

Identification<br />

Female connector<br />

“low profile“<br />

<strong>with</strong> <strong>press</strong>-<strong>in</strong> term<strong>in</strong>ations<br />

5.5 mm<br />

Number Contact<br />

of contacts arrangement<br />

Part No. Performance levels accord<strong>in</strong>g to DIN 41 612. Explanation <strong>chapter</strong> 00<br />

3 2 1<br />

48 09 06 248 7832 09 06 248 6832<br />

32 09 06 232 7832 09 06 232 6832<br />

Female connector<br />

“low profile“<br />

<strong>with</strong> <strong>press</strong>-<strong>in</strong> term<strong>in</strong>ations<br />

32 09 06 232 7892 09 06 232 6892<br />

48 09 06 248 7837 09 06 248 6837<br />

performance level 1<br />

or special<br />

gold plat<strong>in</strong>g<br />

on request<br />

Press-<strong>in</strong><br />

technology<br />

13 mm<br />

32 09 06 232 7837 09 06 232 6837<br />

32 09 06 232 7897 09 06 232 6897<br />

Dimensions<br />

a<br />

5.5<br />

13.0<br />

Board drill<strong>in</strong>gs<br />

Mount<strong>in</strong>g side<br />

all holes<br />

Selectively or fully gold plated wrap posts on request<br />

Other contact arrangements on request<br />

1)<br />

refer to recommended configuration of pcb holes, see page <strong><strong>04</strong>.</strong><strong>04</strong><br />

Dimensions <strong>in</strong> mm<br />

<strong>04</strong> .<br />

21

DIN 41 612 · Type E<br />

Number of contacts<br />

48<br />

Female connectors<br />

Identification<br />

Female connector<br />

<strong>with</strong> <strong>press</strong>-<strong>in</strong> term<strong>in</strong>ations<br />

Number Contact<br />

of contacts arrangement<br />

Part No. Performance levels accord<strong>in</strong>g to DIN 41 612. Explanation <strong>chapter</strong> 00<br />

3 2 1<br />

11.5 mm<br />

48 09 05 248 7851 09 05 248 6851 09 05 248 2851<br />

Press-<strong>in</strong><br />

technology<br />

Dimensions<br />

Press-<strong>in</strong> connection accord<strong>in</strong>g to DIN 41 611 part 5 for pcb<br />

hole diameter (metallised)<br />

Panel cut out<br />

Contact arrangement<br />

view from term<strong>in</strong>ation side<br />

Board drill<strong>in</strong>gs<br />

Mount<strong>in</strong>g side<br />

<strong>04</strong> .<br />

22<br />

VG versions on request<br />

1)<br />

refer to recommended configuration of pcb holes, see page <strong><strong>04</strong>.</strong><strong>04</strong><br />

Dimensions <strong>in</strong> mm

P<strong>in</strong> shroud<br />

Number of contacts<br />

48<br />

II<br />

I<br />

P<strong>in</strong> shrouds<br />

Number<br />

Contact<br />

Identification of contacts arrangement Part No.<br />

P<strong>in</strong> shrouds<br />

pcb thickness (+ 0.2 / – 0.3 mm)<br />

I<br />

II<br />

I<br />

II<br />

<strong>with</strong> fix<strong>in</strong>g brackets 09 05 000 9924 2.8<br />

<strong>with</strong>out fix<strong>in</strong>g brackets<br />

09 05 000 9914 2.8<br />

48 a, c, e<br />

<strong>with</strong> fix<strong>in</strong>g brackets 09 05 000 9922 3.4<br />

<strong>with</strong>out fix<strong>in</strong>g brackets 09 05 000 9912 3.4<br />

Press-<strong>in</strong><br />

technology<br />

Dimensions<br />

row<br />

position<br />

area for friction fit<br />

to <strong>in</strong>terface p<strong>in</strong>s<br />

pcb thickness<br />

X<br />

2.8 (+ 0.2 / – 0.3) 3.6 – 0.1<br />

3.4 (+ 0.2 / – 0.3) 3.0 – 0.1<br />

Dimensions <strong>in</strong> mm<br />

<strong>04</strong> .<br />

23

Technical characteristics accord<strong>in</strong>g to IEC 61076-4-113<br />

Press-<strong>in</strong><br />

technology<br />

Number of contacts 160<br />

Contact spac<strong>in</strong>g (mm) 2.54<br />

Work<strong>in</strong>g current 1 A at 70 °C<br />

and all contacts<br />

are loaded<br />

see current carry<strong>in</strong>g capacity chart<br />

Clearance and creepage distances*<br />

distance <strong>in</strong> mm<br />

m<strong>in</strong>imal clearance and creepage distance 1)<br />

rows a, b, c rows z, d<br />

between two rows<br />

clearance 1.2 1.2<br />

creepage 1.2 1.2<br />

between two contacts clearance 1.2 1.0<br />

(<strong>in</strong> a row) creepage 1.2 1.0<br />

1)<br />

valid for mated and unmated connectors<br />

Work<strong>in</strong>g voltage<br />

The work<strong>in</strong>g voltage also depends accord<strong>in</strong>g to the safety<br />

on the clearance and creepage regulations of the equipment<br />

dimensions of the pcb itself and Explanations see <strong>chapter</strong> 00<br />

the associated wir<strong>in</strong>g<br />

Test voltage U r.m.s.<br />

1 kV<br />

Contact resistance<br />

rows a, b, c<br />

≤ 20 mΩ<br />

rows z, d<br />

≤ 30 mΩ<br />

Insulation resistance ≥ 10 10 Ω acc. to IEC 60512-2<br />

Current carry<strong>in</strong>g capacity<br />

The current carry<strong>in</strong>g capacity is limited by maximum temperature of<br />

materials for <strong>in</strong>serts and contacts <strong>in</strong>clud<strong>in</strong>g term<strong>in</strong>als. The current<br />

capacity curve is valid for cont<strong>in</strong>uous, non <strong>in</strong>terrupted current loaded<br />

contacts of connectors when simultaneous power on all contacts is<br />

given, <strong>with</strong>out exceed<strong>in</strong>g the maximum temperature.<br />

Control and test procedures accord<strong>in</strong>g to DIN IEC 60 512<br />

Work<strong>in</strong>g current<br />

Ambient temperature<br />

Temperature range – 55 °C … + 125 °C<br />

Electrical term<strong>in</strong>ation<br />

Male and female connectors<br />

Diameter of pcb plated through holes<br />

pcb thickness<br />

Recommended pcb holes for<br />

<strong>press</strong>-<strong>in</strong> process acc. to EN 60 352-5 2)<br />

Compliant <strong>press</strong>-<strong>in</strong><br />

term<strong>in</strong>ations<br />

0.94 - 1.09 mm<br />

≥ 1.6 mm<br />

Insertion and <strong>with</strong>drawal force<br />

≤ 160 N<br />

Materials<br />

Mould<strong>in</strong>gs<br />

(LCP),<br />

Contacts<br />

Contact surface<br />

l Liquid Cristal Polymer<br />

for female connectors,<br />

UL 94-V0<br />

l Thermoplastic res<strong>in</strong>,<br />

glass-fibre filled, for<br />

male connectors, UL 94-V0<br />

Copper alloy<br />

Contact zone:<br />

selectively plated 3)<br />

Press-<strong>in</strong> zone:<br />

t<strong>in</strong>ned<br />

selectively plated 3) similar<br />

to the performance level of<br />

the contact zone<br />

<strong>04</strong> .<br />

30<br />

2)<br />

Details see page <strong><strong>04</strong>.</strong><strong>04</strong><br />

3)<br />

Explanation of performance levels see <strong>chapter</strong> 00<br />

* for har-bus ® 64 <strong>in</strong>verse male connectors see <strong>chapter</strong> 06<br />

Tool<strong>in</strong>g see <strong>chapter</strong> 30

· IEC 61 076-4-113<br />

Number of contacts<br />

160<br />

Female connectors<br />

Identification<br />

Female connectors, straight<br />

<strong>with</strong> <strong>press</strong>-<strong>in</strong> term<strong>in</strong>ations<br />

Number of contacts Contact arrangement<br />

Part No. Performance levels accord<strong>in</strong>g to DIN 41 612<br />

Explanation <strong>chapter</strong> 00<br />

2 1<br />

<strong>with</strong> 4.5 / 5 mm* 160 z, a, b, c, d 02 02 160 22<strong>01</strong> 02 02 160 12<strong>01</strong><br />

fix<strong>in</strong>g flange 17 mm* 160 z, a, b, c, d 02 02 160 23<strong>01</strong> 02 02 160 13<strong>01</strong><br />

<strong>with</strong>out 5 mm* 160 z, a, b, c, d 02 02 160 2202 02 02 160 1202<br />

fix<strong>in</strong>g flange 17 mm* 160 z, a, b, c, d 02 02 160 2302 02 02 160 1302<br />

Dimensions<br />

Press-<strong>in</strong><br />

technology<br />

row<br />

position<br />

Board drill<strong>in</strong>gs<br />

Mount<strong>in</strong>g side<br />

Part number<br />

z<br />

Dimension “X” for row<br />

a b c d<br />

02 02 160 22<strong>01</strong> / 02 02 160 12<strong>01</strong> 5.0 4.5 4.5 4.5 5.0<br />

02 02 160 23<strong>01</strong> / 02 02 160 2302 17.0 17.0 17.0 17.0 17.0<br />

02 02 160 2202 / 02 02 160 1202 5.0 5.0 5.0 5.0 5.0<br />

02 02 160 2302 / 02 02 160 1302 17.0 17.0 17.0 17.0 17.0<br />

all holes<br />

position<br />

row<br />

Tool<strong>in</strong>g see <strong>chapter</strong> 30<br />

Additional components see <strong>chapter</strong> 06<br />

* selectively gold-plated<br />

Dimensions <strong>in</strong> mm<br />

<strong>04</strong> .<br />

31

<strong>in</strong>verse · complementary to IEC 61 076-4-113<br />

Number of contacts<br />

160<br />

Male connectors<br />

Identification<br />

Male connectors, straight<br />

<strong>with</strong> <strong>press</strong>-<strong>in</strong> term<strong>in</strong>ations<br />

Number of contacts Contact arrangement<br />

Part No. Performance levels accord<strong>in</strong>g to DIN 41 612<br />

Explanation <strong>chapter</strong> 00<br />

2 1<br />

160 z, a, b, c, d 02 08 160 26<strong>01</strong> 02 08 160 16<strong>01</strong><br />

Press-<strong>in</strong><br />

technology<br />

Dimensions<br />

row<br />

position<br />

Board drill<strong>in</strong>gs<br />

Mount<strong>in</strong>g side<br />

all holes<br />

position<br />

row<br />

<strong>04</strong> .<br />

32<br />

Additional components see <strong>chapter</strong> 06<br />

Tool<strong>in</strong>g see <strong>chapter</strong> 30<br />

Dimensions <strong>in</strong> mm