04. 01 Directory chapter 04 Connectors with press-in termination

04. 01 Directory chapter 04 Connectors with press-in termination

04. 01 Directory chapter 04 Connectors with press-in termination

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

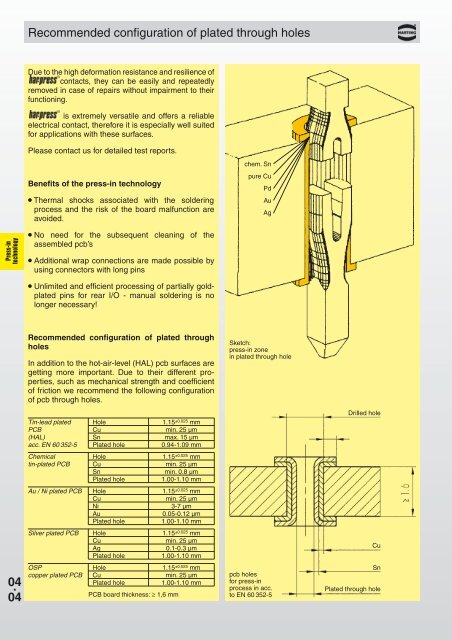

Recommended configuration of plated through holes<br />

Due to the high deformation resistance and resilience of<br />

contacts, they can be easily and repeatedly<br />

removed <strong>in</strong> case of repairs <strong>with</strong>out impairment to their<br />

function<strong>in</strong>g.<br />

is extremely versatile and offers a reliable<br />

electrical contact, therefore it is especially well suited<br />

for applications <strong>with</strong> these surfaces.<br />

Please contact us for detailed test reports.<br />

chem. Sn<br />

Benefits of the <strong>press</strong>-<strong>in</strong> technology<br />

l Thermal shocks associated <strong>with</strong> the solder<strong>in</strong>g<br />

process and the risk of the board malfunction are<br />

avoided.<br />

pure Cu<br />

Pd<br />

Au<br />

Ag<br />

Press-<strong>in</strong><br />

technology<br />

l No need for the subsequent clean<strong>in</strong>g of the<br />

assembled pcb’s<br />

l Additional wrap connections are made possible by<br />

us<strong>in</strong>g connectors <strong>with</strong> long p<strong>in</strong>s<br />

l Unlimited and efficient process<strong>in</strong>g of partially goldplated<br />

p<strong>in</strong>s for rear I/O - manual solder<strong>in</strong>g is no<br />

longer necessary!<br />

Recommended configuration of plated through<br />

holes<br />

In addition to the hot-air-level (HAL) pcb surfaces are<br />

gett<strong>in</strong>g more important. Due to their different properties,<br />

such as mechanical strength and coefficient<br />

of friction we recommend the follow<strong>in</strong>g configuration<br />

of pcb through holes.<br />

Sketch:<br />

<strong>press</strong>-<strong>in</strong> zone<br />

<strong>in</strong> plated through hole<br />

T<strong>in</strong>-lead plated Hole 1.15 ±0.025 mm<br />

PCB Cu m<strong>in</strong>. 25 µm<br />

(HAL) Sn max. 15 µm<br />

acc. EN 60 352-5 Plated hole 0.94-1.09 mm<br />

Drilled hole<br />

Chemical Hole 1.15 ±0.025 mm<br />

t<strong>in</strong>-plated PCB Cu m<strong>in</strong>. 25 µm<br />

Sn m<strong>in</strong>. 0.8 µm<br />

Plated hole<br />

1.00-1.10 mm<br />

Au / Ni plated PCB Hole 1.15 ±0.025 mm<br />

Cu m<strong>in</strong>. 25 µm<br />

Ni 3-7 µm<br />

Au 0.05-0.12 µm<br />

Plated hole<br />

1.00-1.10 mm<br />

Silver plated PCB Hole 1.15 ±0.025 mm<br />

Cu m<strong>in</strong>. 25 µm<br />

Ag 0.1-0.3 µm<br />

Plated hole<br />

1.00-1.10 mm<br />

Cu<br />

<strong>04</strong> .<br />

<strong>04</strong><br />

OSP Hole 1.15 ±0.025 mm<br />

copper plated PCB Cu m<strong>in</strong>. 25 µm<br />

Plated hole<br />

1.00-1.10 mm<br />

PCB board thickness: ≥ 1,6 mm<br />

pcb holes<br />

for <strong>press</strong>-<strong>in</strong><br />

process <strong>in</strong> acc.<br />

to EN 60 352-5<br />

Sn<br />

Plated through hole