Download PDF version English(2664KB) - Hamon

Download PDF version English(2664KB) - Hamon

Download PDF version English(2664KB) - Hamon

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

44<br />

<strong>Hamon</strong> Annual Report 2010<br />

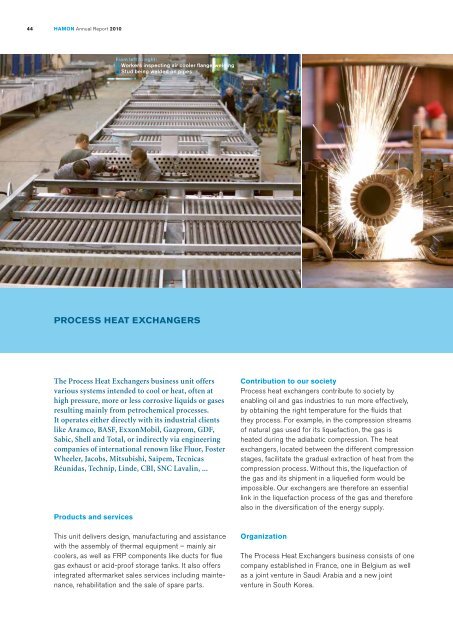

From left to right :<br />

Workers inspecting air cooler flange welding<br />

Stud being welded on pipes<br />

Process Heat Exchangers<br />

The Process Heat Exchangers business unit offers<br />

various systems intended to cool or heat, often at<br />

high pressure, more or less corrosive liquids or gases<br />

resulting mainly from petrochemical processes.<br />

It operates either directly with its industrial clients<br />

like Aramco, BASF, ExxonMobil, Gazprom, GDF,<br />

Sabic, Shell and Total, or indirectly via engineering<br />

companies of international renown like Fluor, Foster<br />

Wheeler, Jacobs, Mitsubishi, Saipem, Tecnicas<br />

Réunidas, Technip, Linde, CBI, SNC Lavalin, ...<br />

Products and services<br />

This unit delivers design, manufacturing and assistance<br />

with the assembly of thermal equipment – mainly air<br />

coolers, as well as FRP components like ducts for flue<br />

gas exhaust or acid-proof storage tanks. It also offers<br />

integrated aftermarket sales services including maintenance,<br />

rehabilitation and the sale of spare parts.<br />

Contribution to our society<br />

Process heat exchangers contribute to society by<br />

enabling oil and gas industries to run more effectively,<br />

by obtaining the right temperature for the fluids that<br />

they process. For example, in the compression streams<br />

of natural gas used for its liquefaction, the gas is<br />

heated during the adiabatic compression. The heat<br />

exchangers, located between the different compression<br />

stages, facilitate the gradual extraction of heat from the<br />

compression process. Without this, the liquefaction of<br />

the gas and its shipment in a liquefied form would be<br />

impossible. Our exchangers are therefore an essential<br />

link in the liquefaction process of the gas and therefore<br />

also in the diversification of the energy supply.<br />

Organization<br />

The Process Heat Exchangers business consists of one<br />

company established in France, one in Belgium as well<br />

as a joint venture in Saudi Arabia and a new joint<br />

venture in South Korea.