Issue 014 - Bike Business Magazine Home Page

Issue 014 - Bike Business Magazine Home Page

Issue 014 - Bike Business Magazine Home Page

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

t e c h o t a l k<br />

Oxygen Sensors<br />

Written by Clive Ward, www.motorcyclebiz.com.au<br />

The way they work, the effect they<br />

have on the engine management system<br />

and a way of testing them.<br />

In most Oxygen Sensors there is a<br />

Zirconia element that, when heated to<br />

temperatures above approximately 300<br />

deg C, produce voltages that are based<br />

on the oxygen content surrounding the<br />

sensor tip, as compared to the oxygen in<br />

the atmosphere.<br />

Oxygen sensors perform this<br />

comparison through an atmospheric<br />

reference orifice in the sensor housing.<br />

If the atmospheric reference orifice<br />

is blocked with road grime, mud or<br />

in some cases, dried crankcase oil,<br />

the performance of the sensor will<br />

be impaired to a point that will cause<br />

poor fuel economy, excessive exhaust<br />

emissions and in severe cases,<br />

motorcycle rideability problems.<br />

Always visually inspect the oxygen<br />

sensor. If the sensor is externally<br />

covered with any form of contaminant<br />

there is a very good likelihood that the<br />

sensor will not perform to optimum<br />

capacity due to the atmospheric<br />

reference orifice being blocked.<br />

Pay particular attention to oxygen<br />

sensors that are located on off-road<br />

Motorcycles as they are prone to mud<br />

contamination.<br />

Another easy to perform physical<br />

test, is to determine whether or not<br />

the sensor is securely tightened in the<br />

exhaust system. Because any electrical<br />

circuit has to be complete before the<br />

current can flow, poor contact between<br />

the sensor securing thread (sensor<br />

grounding point) and the exhaust system<br />

will cause erratic, poor, or incorrect<br />

oxygen sensor signals to be sent to the<br />

ECU, also check that the exhaust is tight.<br />

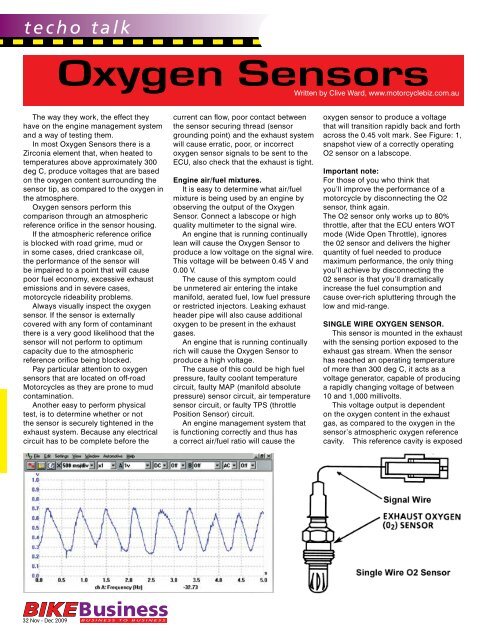

Engine air/fuel mixtures.<br />

It is easy to determine what air/fuel<br />

mixture is being used by an engine by<br />

observing the output of the Oxygen<br />

Sensor. Connect a labscope or high<br />

quality multimeter to the signal wire.<br />

An engine that is running continually<br />

lean will cause the Oxygen Sensor to<br />

produce a low voltage on the signal wire.<br />

This voltage will be between 0.45 V and<br />

0.00 V.<br />

The cause of this symptom could<br />

be unmetered air entering the intake<br />

manifold, aerated fuel, low fuel pressure<br />

or restricted injectors. Leaking exhaust<br />

header pipe will also cause additional<br />

oxygen to be present in the exhaust<br />

gases.<br />

An engine that is running continually<br />

rich will cause the Oxygen Sensor to<br />

produce a high voltage.<br />

The cause of this could be high fuel<br />

pressure, faulty coolant temperature<br />

circuit, faulty MAP (manifold absolute<br />

pressure) sensor circuit, air temperature<br />

sensor circuit, or faulty TPS (throttle<br />

Position Sensor) circuit.<br />

An engine management system that<br />

is functioning correctly and thus has<br />

a correct air/fuel ratio will cause the<br />

oxygen sensor to produce a voltage<br />

that will transition rapidly back and forth<br />

across the 0.45 volt mark. See Figure: 1,<br />

snapshot view of a correctly operating<br />

O2 sensor on a labscope.<br />

Important note:<br />

For those of you who think that<br />

you’ll improve the performance of a<br />

motorcycle by disconnecting the O2<br />

sensor, think again.<br />

The O2 sensor only works up to 80%<br />

throttle, after that the ECU enters WOT<br />

mode (Wide Open Throttle), ignores<br />

the 02 sensor and delivers the higher<br />

quantity of fuel needed to produce<br />

maximum performance, the only thing<br />

you’ll achieve by disconnecting the<br />

02 sensor is that you’ll dramatically<br />

increase the fuel consumption and<br />

cause over-rich spluttering through the<br />

low and mid-range.<br />

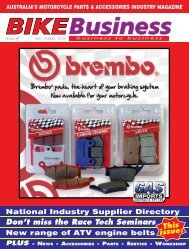

SINGLE WIRE OXYGEN SENSOR.<br />

This sensor is mounted in the exhaust<br />

with the sensing portion exposed to the<br />

exhaust gas stream. When the sensor<br />

has reached an operating temperature<br />

of more than 300 deg C, it acts as a<br />

voltage generator, capable of producing<br />

a rapidly changing voltage of between<br />

10 and 1,000 millivolts.<br />

This voltage output is dependent<br />

on the oxygen content in the exhaust<br />

gas, as compared to the oxygen in the<br />

sensor’s atmospheric oxygen reference<br />

cavity. This reference cavity is exposed<br />

BIKE<strong>Business</strong><br />

32 Nov - Dec 2009 b u s i n e s s t o b u s i n e s s