6 - Kuwait Oil Company

6 - Kuwait Oil Company

6 - Kuwait Oil Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Insoluble low gravity solids are drilled cuttings that<br />

are ground up so fine that cannot be removed by<br />

mechanical means. LGS are the worst enemy of<br />

the drilling fluids. In any mud system, the problems<br />

associated with solids are mainly due to low gravity<br />

solids. Controlling the low gravity solids are vital<br />

for the success. If the particle size is less than 5<br />

microns, then the drilled solids remain in the mud.<br />

Indications of High Solids in the Drilling Fluid<br />

There are several indications from which one can<br />

monitor the solid build-up in the drilling mud.<br />

- The first visible indication of solids building up on<br />

the mud is an increase in mud viscosity without the<br />

addition of a viscosifier. This takes place gradually and<br />

it is understood that most significant contribution to<br />

the fluid viscosity comes from the low gravity solids.<br />

- Progressive increase in the plastic viscosity is<br />

another main indicator of building up of LGS<br />

in the mud. PV primarily depends on the size,<br />

shape and the number of solids in the mud.<br />

- Sometimes in the mud, it can be observed that<br />

phenomenal increases occur in the YP and gel strengths.<br />

This happens due to high LGS in the mud system. In<br />

this case any mud treatment will be less effective.<br />

- Increase in fluid loss and deteriorated filter cake.<br />

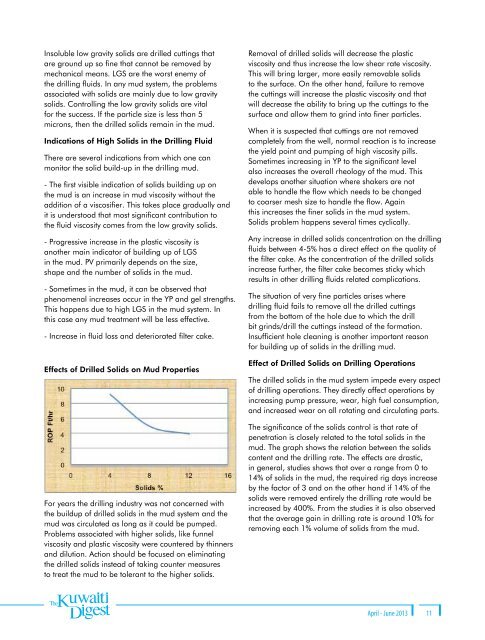

Effects of Drilled Solids on Mud Properties<br />

For years the drilling industry was not concerned with<br />

the buildup of drilled solids in the mud system and the<br />

mud was circulated as long as it could be pumped.<br />

Problems associated with higher solids, like funnel<br />

viscosity and plastic viscosity were countered by thinners<br />

and dilution. Action should be focused on eliminating<br />

the drilled solids instead of taking counter measures<br />

to treat the mud to be tolerant to the higher solids.<br />

Removal of drilled solids will decrease the plastic<br />

viscosity and thus increase the low shear rate viscosity.<br />

This will bring larger, more easily removable solids<br />

to the surface. On the other hand, failure to remove<br />

the cuttings will increase the plastic viscosity and that<br />

will decrease the ability to bring up the cuttings to the<br />

surface and allow them to grind into finer particles.<br />

When it is suspected that cuttings are not removed<br />

completely from the well, normal reaction is to increase<br />

the yield point and pumping of high viscosity pills.<br />

Sometimes increasing in YP to the significant level<br />

also increases the overall rheology of the mud. This<br />

develops another situation where shakers are not<br />

able to handle the flow which needs to be changed<br />

to coarser mesh size to handle the flow. Again<br />

this increases the finer solids in the mud system.<br />

Solids problem happens several times cyclically.<br />

Any increase in drilled solids concentration on the drilling<br />

fluids between 4-5% has a direct effect on the quality of<br />

the filter cake. As the concentration of the drilled solids<br />

increase further, the filter cake becomes sticky which<br />

results in other drilling fluids related complications.<br />

The situation of very fine particles arises where<br />

drilling fluid fails to remove all the drilled cuttings<br />

from the bottom of the hole due to which the drill<br />

bit grinds/drill the cuttings instead of the formation.<br />

Insufficient hole cleaning is another important reason<br />

for building up of solids in the drilling mud.<br />

Effect of Drilled Solids on Drilling Operations<br />

The drilled solids in the mud system impede every aspect<br />

of drilling operations. They directly affect operations by<br />

increasing pump pressure, wear, high fuel consumption,<br />

and increased wear on all rotating and circulating parts.<br />

The significance of the solids control is that rate of<br />

penetration is closely related to the total solids in the<br />

mud. The graph shows the relation between the solids<br />

content and the drilling rate. The effects are drastic,<br />

in general, studies shows that over a range from 0 to<br />

14% of solids in the mud, the required rig days increase<br />

by the factor of 3 and on the other hand if 14% of the<br />

solids were removed entirely the drilling rate would be<br />

increased by 400%. From the studies it is also observed<br />

that the average gain in drilling rate is around 10% for<br />

removing each 1% volume of solids from the mud.<br />

April - June 2013 11