6 - Kuwait Oil Company

6 - Kuwait Oil Company

6 - Kuwait Oil Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

the application window and should be used carefully<br />

by trained Engineer. The expert system does not<br />

replace the expert but does aid the engineer in the<br />

decision and speed up the selection process and<br />

minimize the dependence on A/L consultants.<br />

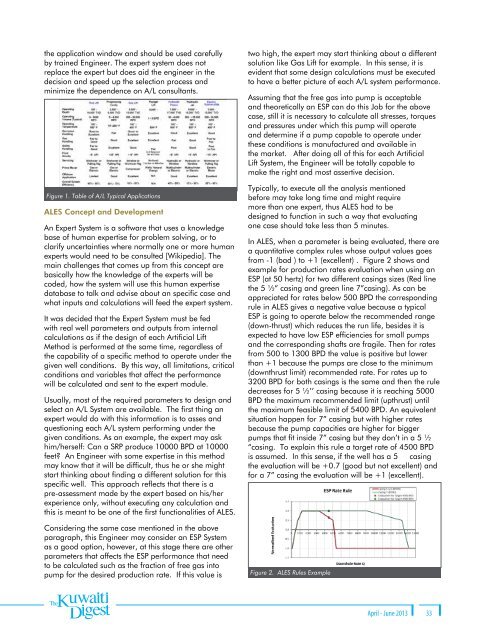

Figure 1. Table of A/L Typical Applications<br />

ALES Concept and Development<br />

An Expert System is a software that uses a knowledge<br />

base of human expertise for problem solving, or to<br />

clarify uncertainties where normally one or more human<br />

experts would need to be consulted [Wikipedia]. The<br />

main challenges that comes up from this concept are<br />

basically how the knowledge of the experts will be<br />

coded, how the system will use this human expertise<br />

database to talk and advise about an specific case and<br />

what inputs and calculations will feed the expert system.<br />

It was decided that the Expert System must be fed<br />

with real well parameters and outputs from internal<br />

calculations as if the design of each Artificial Lift<br />

Method is performed at the same time, regardless of<br />

the capability of a specific method to operate under the<br />

given well conditions. By this way, all limitations, critical<br />

conditions and variables that affect the performance<br />

will be calculated and sent to the expert module.<br />

Usually, most of the required parameters to design and<br />

select an A/L System are available. The first thing an<br />

expert would do with this information is to asses and<br />

questioning each A/L system performing under the<br />

given conditions. As an example, the expert may ask<br />

him/herself: Can a SRP produce 10000 BPD at 10000<br />

feet An Engineer with some expertise in this method<br />

may know that it will be difficult, thus he or she might<br />

start thinking about finding a different solution for this<br />

specific well. This approach reflects that there is a<br />

pre-assessment made by the expert based on his/her<br />

experience only, without executing any calculation and<br />

this is meant to be one of the first functionalities of ALES.<br />

Considering the same case mentioned in the above<br />

paragraph, this Engineer may consider an ESP System<br />

as a good option, however, at this stage there are other<br />

parameters that affects the ESP performance that need<br />

to be calculated such as the fraction of free gas into<br />

pump for the desired production rate. If this value is<br />

two high, the expert may start thinking about a different<br />

solution like Gas Lift for example. In this sense, it is<br />

evident that some design calculations must be executed<br />

to have a better picture of each A/L system performance.<br />

Assuming that the free gas into pump is acceptable<br />

and theoretically an ESP can do this Job for the above<br />

case, still it is necessary to calculate all stresses, torques<br />

and pressures under which this pump will operate<br />

and determine if a pump capable to operate under<br />

these conditions is manufactured and available in<br />

the market. After doing all of this for each Artificial<br />

Lift System, the Engineer will be totally capable to<br />

make the right and most assertive decision.<br />

Typically, to execute all the analysis mentioned<br />

before may take long time and might require<br />

more than one expert, thus ALES had to be<br />

designed to function in such a way that evaluating<br />

one case should take less than 5 minutes.<br />

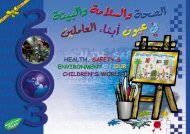

In ALES, when a parameter is being evaluated, there are<br />

a quantitative complex rules whose output values goes<br />

from -1 (bad ) to +1 (excellent) . Figure 2 shows and<br />

example for production rates evaluation when using an<br />

ESP (at 50 hertz) for two different casings sizes (Red line<br />

the 5 ½” casing and green line 7”casing). As can be<br />

appreciated for rates below 500 BPD the corresponding<br />

rule in ALES gives a negative value because a typical<br />

ESP is going to operate below the recommended range<br />

(down-thrust) which reduces the run life, besides it is<br />

expected to have low ESP efficiencies for small pumps<br />

and the corresponding shafts are fragile. Then for rates<br />

from 500 to 1300 BPD the value is positive but lower<br />

than +1 because the pumps are close to the minimum<br />

(downthrust limit) recommended rate. For rates up to<br />

3200 BPD for both casings is the same and then the rule<br />

decreases for 5 ½’’ casing because it is reaching 5000<br />

BPD the maximum recommended limit (upthrust) until<br />

the maximum feasible limit of 5400 BPD. An equivalent<br />

situation happen for 7” casing but with higher rates<br />

because the pump capacities are higher for bigger<br />

pumps that fit inside 7” casing but they don’t in a 5 ½<br />

“casing. To explain this rule a target rate of 4500 BPD<br />

is assumed. In this sense, if the well has a 5 ½ casing<br />

the evaluation will be +0.7 (good but not excellent) and<br />

for a 7” casing the evaluation will be +1 (excellent).<br />

Figure 2. ALES Rules Example<br />

April - June 2013 33