6 - Kuwait Oil Company

6 - Kuwait Oil Company

6 - Kuwait Oil Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

stagnant areas with the intrusion of foreign materials.<br />

KOC came across many situations where hydrocarbon<br />

release incidents occurred due to accelerated excessive<br />

internal corrosion on the walls of the dead legs. The<br />

root cause of such acceleration is the accumulation of<br />

trapped corroding materials referred to as ‘stagnant<br />

oily water’ on the internal walls of the dead legs.<br />

But how are these dead legs responsible for that<br />

hazard Export Operations teams discovered that there<br />

were two immediate causes to this. The first immediate<br />

cause is the perforation of the girth welds at the 6<br />

o’clock position. The perforation (corrosion) was caused<br />

by water separation from crude at the dead legs. The<br />

perforation was then accelerated by the imperfections in<br />

welds (deep incomplete penetration effect). The second<br />

immediate cause was wherever there was excessive<br />

material loss due to pitting corrosion (in some cases<br />

45-65% reduction in original pipe/elbow thickness),<br />

which rendered the drain pipe segment completely<br />

unreliable. Even if it were not leaking at the time of<br />

the inspection, a leak may occur should the location of<br />

the heavy corrosion coincide with external corrosion,<br />

excessive loads or when there is a pipe surge due to bad<br />

operations. Both immediate causes of deposit corrosion<br />

will eventually lead to the failure of the drain segment.<br />

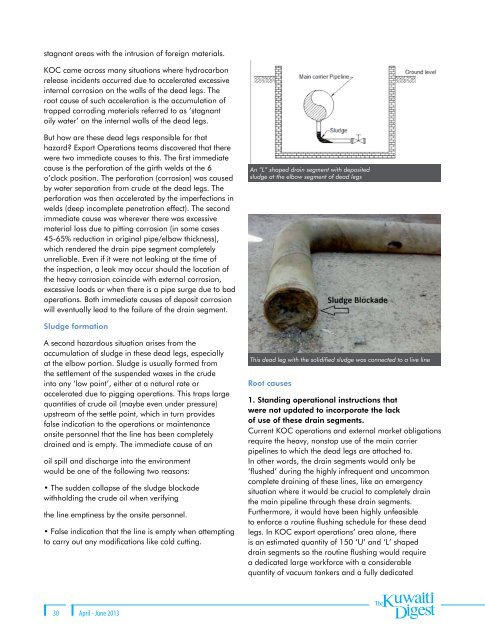

An “L” shaped drain segment with deposited<br />

sludge at the elbow segment of dead legs<br />

Sludge formation<br />

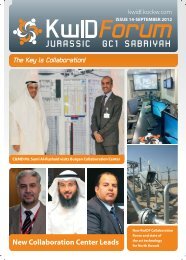

A second hazardous situation arises from the<br />

accumulation of sludge in these dead legs, especially<br />

at the elbow portion. Sludge is usually formed from<br />

the settlement of the suspended waxes in the crude<br />

into any ‘low point’, either at a natural rate or<br />

accelerated due to pigging operations. This traps large<br />

quantities of crude oil (maybe even under pressure)<br />

upstream of the settle point, which in turn provides<br />

false indication to the operations or maintenance<br />

onsite personnel that the line has been completely<br />

drained and is empty. The immediate cause of an<br />

oil spill and discharge into the environment<br />

would be one of the following two reasons:<br />

• The sudden collapse of the sludge blockade<br />

withholding the crude oil when verifying<br />

the line emptiness by the onsite personnel.<br />

• False indication that the line is empty when attempting<br />

to carry out any modifications like cold cutting.<br />

This dead leg with the solidified sludge was connected to a live line<br />

Root causes<br />

1. Standing operational instructions that<br />

were not updated to incorporate the lack<br />

of use of these drain segments.<br />

Current KOC operations and external market obligations<br />

require the heavy, nonstop use of the main carrier<br />

pipelines to which the dead legs are attached to.<br />

In other words, the drain segments would only be<br />

‘flushed’ during the highly infrequent and uncommon<br />

complete draining of these lines, like an emergency<br />

situation where it would be crucial to completely drain<br />

the main pipeline through these drain segments.<br />

Furthermore, it would have been highly unfeasible<br />

to enforce a routine flushing schedule for these dead<br />

legs. In KOC export operations’ area alone, there<br />

is an estimated quantity of 150 ‘U’ and ‘L’ shaped<br />

drain segments so the routine flushing would require<br />

a dedicated large workforce with a considerable<br />

quantity of vacuum tankers and a fully dedicated<br />

30<br />

April - June 2013