Vulcraft Steel Joists and Joist Girders Catalog - Sites at Lafayette

Vulcraft Steel Joists and Joist Girders Catalog - Sites at Lafayette

Vulcraft Steel Joists and Joist Girders Catalog - Sites at Lafayette

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

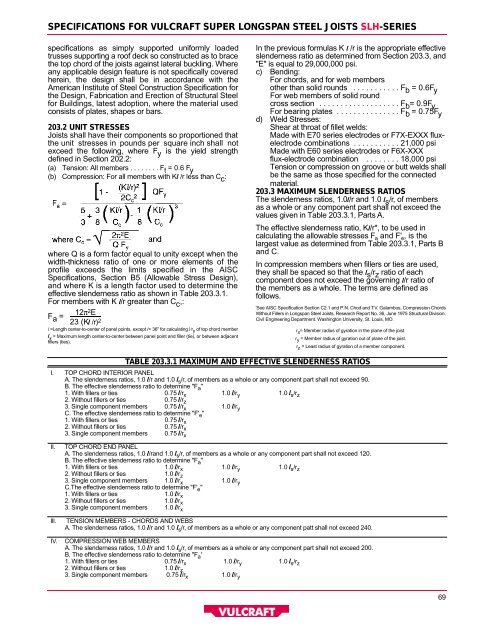

S P E C I F I C ATIONS FOR VULCRAFT SUPER LONGSPAN STEEL JOISTS S L H- S E R I E S<br />

specific<strong>at</strong>ions as simply supported uniformly loaded<br />

trusses supporting a roof deck so constructed as to brace<br />

the top chord of the joists against l<strong>at</strong>eral buckling. Where<br />

any applicable design fe<strong>at</strong>ure is not specifically covered<br />

herein, the design shall be in accordance with the<br />

American Institute of <strong>Steel</strong> Construction Specific<strong>at</strong>ion for<br />

the Design, Fabric<strong>at</strong>ion <strong>and</strong> Erection of Structural <strong>Steel</strong><br />

for Buildings, l<strong>at</strong>est adoption, where the m<strong>at</strong>erial used<br />

consists of pl<strong>at</strong>es, shapes or bars.<br />

203.2 UNIT STRESSES<br />

<strong><strong>Joist</strong>s</strong> shall have their components so proportioned th<strong>at</strong><br />

the unit stresses in pounds per square inch shall not<br />

exceed the following, where F y is the yield strength<br />

defined in Section 202.2:<br />

( a ) Tension: All members . . . . . . . . F t = 0.6 F y<br />

( b ) Compression: For all members with Kl /r less than C c :<br />

where Q is a form factor equal to unity except when the<br />

width-thickness r<strong>at</strong>io of one or more elements of the<br />

profile exceeds the limits specified in the AISC<br />

Specific<strong>at</strong>ions, Section B5 (Allowable Stress Design),<br />

<strong>and</strong> where K is a length factor used to determine the<br />

e ffective slenderness r<strong>at</strong>io as shown in Table 203.3.1.<br />

For rnembers with K l/r gre<strong>at</strong>er than C c ,:<br />

12 π<br />

F a =<br />

2 E<br />

23 (Kl / r ) 2<br />

l =Length center-to-center of panel points, except l= 36" for calcul<strong>at</strong>ing l /r y of top chord member<br />

l s = Maximum length center-to-center between panel point <strong>and</strong> filler (tie), or between adjacent<br />

fillers (ties).<br />

In the previous formulas K l /r is the appropri<strong>at</strong>e eff e c t i v e<br />

slenderness r<strong>at</strong>io as determined from Section 203.3, <strong>and</strong><br />

"E" is equal to 29,000,000 psi.<br />

c ) B e n d i n g :<br />

For chords, <strong>and</strong> for web members<br />

other than solid rounds . . . . . . . . . . . F b = 0.6F y<br />

For web members of solid round<br />

cross section . . . . . . . . . . . . . . . . . . . F b = 0.9F y<br />

For bearing pl<strong>at</strong>es . . . . . . . . . . . . . . . F b = 0.75F y<br />

d ) Weld Stresses:<br />

Shear <strong>at</strong> thro<strong>at</strong> of fillet welds:<br />

Made with E70 series electrodes or F7X-EXXX fluxelectrode<br />

combin<strong>at</strong>ions . . . . . . . . . . . 21,000 psi<br />

Made with E60 series electrodes or F6X-XXX<br />

flux-electrode combin<strong>at</strong>ion . . . . . . . . 18,000 psi<br />

Tension or compression on groove or butt welds shall<br />

be the same as those specified for the connected<br />

m a t e r i a l .<br />

203.3 MAXIMUM SLENDERNESS RAT I O S<br />

The slenderness r<strong>at</strong>ios, 1.0l/r <strong>and</strong> 1.0 l s / r, of members<br />

as a whole or any component part shall not exceed the<br />

values given in Table 203.3.1, Parts A .<br />

The effective slenderness r<strong>at</strong>io, Kl/r*, to be used in<br />

calcul<strong>at</strong>ing the allowable stresses F a <strong>and</strong> F' e , is the<br />

largest value as determined from Table 203.3.1, Parts B<br />

<strong>and</strong> C.<br />

In compression members when fillers or ties are used,<br />

they shall be spaced so th<strong>at</strong> the l s / r z r<strong>at</strong>io of each<br />

component does not exceed the governing l/r r<strong>at</strong>io of<br />

the members as a whole. The terms are defined as<br />

f o l l o w s .<br />

'See AISC Specific<strong>at</strong>ion Section C2.1 <strong>and</strong> P.N. Chod <strong>and</strong> T. V. Galambos, Compression Chords<br />

Without Fillers in Longspan <strong>Steel</strong> <strong><strong>Joist</strong>s</strong>, Research Report No. 36, June 1975 Structural Division,<br />

Civil Engineering Department. Washington University, St. Louis, MO.<br />

r x = Member radius of gyr<strong>at</strong>ion in the plane of the joist.<br />

r y = Member radius of gyr<strong>at</strong>ion out of plane of the joist.<br />

r z = Least radius of gyr<strong>at</strong>ion of a member component.<br />

I .<br />

I I .<br />

I l l .<br />

I V.<br />

TABLE 203.3.1 MAXIMUM AND EFFECTIVE SLENDERNESS RAT I O S<br />

TO P CHORD INTERIOR PA N E L<br />

A. The slenderness r<strong>at</strong>ios, 1.0 l/r <strong>and</strong> 1.0 l s / r, of members as a whole or any component part shall not exceed 90.<br />

B. The effective slenderness r<strong>at</strong>io to determine "F a "<br />

1. With fillers or ties 0.75 l/ r x 1.0 l/ r y 1.0 l s / r z<br />

2. Without fillers or ties 0.75 l/ r z<br />

3. Single component members 0.75 l/ r x 1.0 l/ r y<br />

C. The effective slenderness r<strong>at</strong>io to determine "F' e "<br />

1. With fillers or ties 0.75 l/ r x<br />

2. Without fillers or ties 0.75 l/ r x<br />

3. Single component members 0.75 l/ r x<br />

TO P CHORD END PA N E L<br />

A. The slenderness r<strong>at</strong>ios, 1.0 l/r<strong>and</strong> 1.0 l s / r, of members as a whole or any component part shall not exceed 120.<br />

B. The effective slenderness r<strong>at</strong>io to determine "F a "<br />

1. With fillers or ties 1.0 l/ r x 1.0 l/ r y 1.0 l s / r z<br />

2. Without fillers or ties 1.0 l/ r z<br />

3. Single component members 1.0 l/ r x 1.0 l/ r y<br />

C.The effective slenderness r<strong>at</strong>io to determine "F' e "<br />

1. With fillers or ties 1.0 l/ r x<br />

2. Without fillers or ties 1.0 l/ r x<br />

3. Single component members 1.0 l/ r x<br />

TENSION MEMBERS - CHORDS AND WEBS<br />

A. The slenderness r<strong>at</strong>ios, 1.0 l/r <strong>and</strong> 1.0 l s / r, of members as a whole or any component p<strong>at</strong>t shall not exceed 240.<br />

COMPRESSION WEB MEMBERS<br />

A. The slenderness r<strong>at</strong>ios, 1.0 l/r <strong>and</strong> 1.0 l s / r, of members as a whole or any component part shall not exceed 200.<br />

B. The effective slenderness r<strong>at</strong>io to determine "F a '<br />

1. With fillers or ties 0.75 l/ r x 1.0 l/ r y 1.0 l s / r z<br />

2. Without fillers or ties 1.0 l/ r z<br />

3. Single component members 0.75 l/ r x 1.0 l/ r y<br />

6 9