POWER UP A WINNER - Plant Services

POWER UP A WINNER - Plant Services

POWER UP A WINNER - Plant Services

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

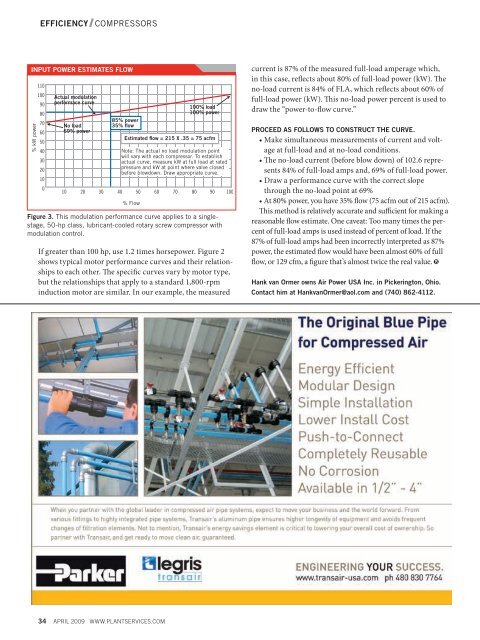

0 13 25 48 50 63 75 88 100<br />

% Power (kW)<br />

Note:<br />

Efficiency / Compressors<br />

1. These operating characteristics will vary with motor type,<br />

basic design, motor efficiency, constant or variable speed, etc.<br />

2. Amperage will vary indirectly with changes in rated voltage.<br />

It is best to measure kW directly.<br />

3. 87% amp = 80% power<br />

Input power estimates flow<br />

% kW power<br />

110<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

Actual modulation<br />

performace curve<br />

No load<br />

69% power<br />

85% power<br />

35% flow<br />

% Flow<br />

100% load<br />

100% power<br />

Estimated flow = 215 X .35 = 75 acfm<br />

Note: The actual no load modulation point<br />

will vary with each compressor. To establish<br />

actual curve, measure kW at full load at rated<br />

pressure and kW at point where valve closed<br />

before blowdown. Draw appropriate curve.<br />

10 20 30 40 50 60 70 80 90 100<br />

Figure 3. This modulation performance curve applies to a singlestage,<br />

50-hp class, lubricant-cooled rotary screw compressor with<br />

modulation control.<br />

If greater than 100 hp, use 1.2 times horsepower. Figure 2<br />

shows typical motor performance curves and their relationships<br />

to each other. The specific curves vary by motor type,<br />

but the relationships that apply to a standard 1,800-rpm<br />

induction motor are similar. In our example, the measured<br />

current is 87% of the measured full-load amperage which,<br />

in this case, reflects about 80% of full-load power (kW). The<br />

no-load current is 84% of FLA, which reflects about 60% of<br />

full-load power (kW). This no-load power percent is used to<br />

draw the “power-to-flow curve.”<br />

Proceed as follows to construct the curve.<br />

• Make simultaneous measurements of current and voltage<br />

at full-load and at no-load conditions.<br />

• The no-load current (before blow down) of 102.6 represents<br />

84% of full-load amps and, 69% of full-load power.<br />

• Draw a performance curve with the correct slope<br />

through the no-load point at 69%<br />

• At 80% power, you have 35% flow (75 acfm out of 215 acfm).<br />

This method is relatively accurate and sufficient for making a<br />

reasonable flow estimate. One caveat: Too many times the percent<br />

of full-load amps is used instead of percent of load. If the<br />

87% of full-load amps had been incorrectly interpreted as 87%<br />

power, the estimated flow would have been almost 60% of full<br />

flow, or 129 cfm, a figure that’s almost twice the real value.<br />

Hank van Ormer owns Air Power USA Inc. in Pickerington, Ohio.<br />

Contact him at HankvanOrmer@aol.com and (740) 862-4112.<br />

34 APRIL 2009 www.PLANTSERVICES.com